Under the wings of a swan. Engineering secrets of the main arch of Lakhta Center

At the end of the summer in Lakhta Center they accepted a new challenge. This is about the installation of the Arch of the main entrance. Builders really need to have time to assemble basic metal structures to zero degrees.

The winter is coming. It is important to make it to her.

The arch of the main entrance itself is interesting not only by this fact. I do not want to use the description already wiped in relation to Lakhta Center - “a unique construction”, but there is no way out. The entrance to the complex is a unique design.

Firstly, because the unsupported span of the arch is 125 meters. At the same time, the generally accepted point of reference for the uniqueness of large-span and unsupported is “only” 60 meters.

Secondly - the functionality of the arch: this is the entrance to the tower, but made in the form of a separate building.

Why did they do that? How will this long-span magnificence hold on? Why keep up before the cold? All answers - under the cut.

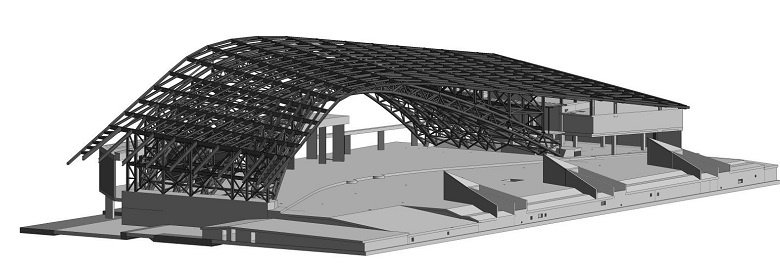

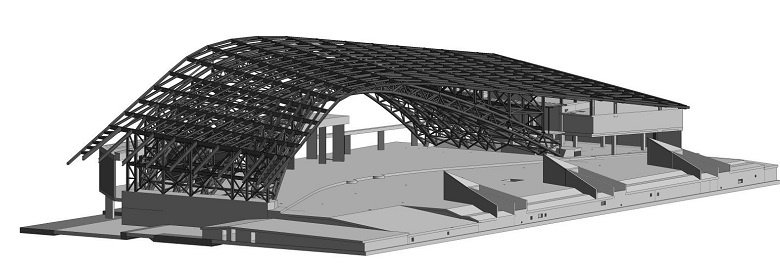

Visualization of the Arch of the main entrance to Lakhta Center

The arch is perhaps one of the most monumental architectural elements and, of course, the stingy definition “curvilinear overlapping of the aperture between two supports” does not convey its essence.

Modern architecture is the most complex area in which science and art are harmoniously combined. The most ambitious architectural solutions - akin to launching a rocket into space: the most accurate mathematical calculations, plus the subtlest understanding of the laws of physics and the ability to use them to their advantage. But at the same time, objectively, most of these decisions are an attempt to repeat, and ultimately surpass the creations of the greatest architect, nature. This fully applies to the arched structures. Just look at the largest natural arch in the world - the Fay Xiangren Bridge in northwest China with a 120-meter span.

Fei Xiangren, China

Or the world's oldest Landscape Arch at Arches National Park in Utah. The span is also rather big - 63 m, and in the thinnest part the width of the arch does not exceed 2 m.

Landscape Arch, USA

Of course, the “Gateway of the West” arch in St. Louis (Missouri, USA) is a larger facility (192 m at the top and 192 m wide at the base is a world record) and geometrically adjusted. But there are no fundamental differences from natural arches.

"Gateway of the West", USA, 1965

The most famous in the world, of course, is the “Triumphal Arch” on Charles de Gaulle Square in Paris, erected by architect Jean Shalgren in 1806–36 in commemoration of the victories of the Napoleonic army. Perhaps it is this image that occurs in the thoughts of most people in the world with the word “arch”.

Arc de Triomphe, Paris, 1836

Although Muscovites will probably present the Triumphal Gate on Kutuzovsky,

Triumphal Gate, Moscow. Copy, 1968. The original was erected on the square of the Tverskaya gates in 1829-1834, dismantled in 1936.

Petersburgers - Narva Gates.

Narva Triumphal Gate, St. Petersburg, 1834

All these structures are impressive, beautiful, but perform primarily a decorative function. Even despite the observation deck, located at the top of the "Gateway of the West" or small museums in the interior of the Paris Arc de Triomphe or the St. Petersburg Narva Gate, these objects are difficult to call functional.

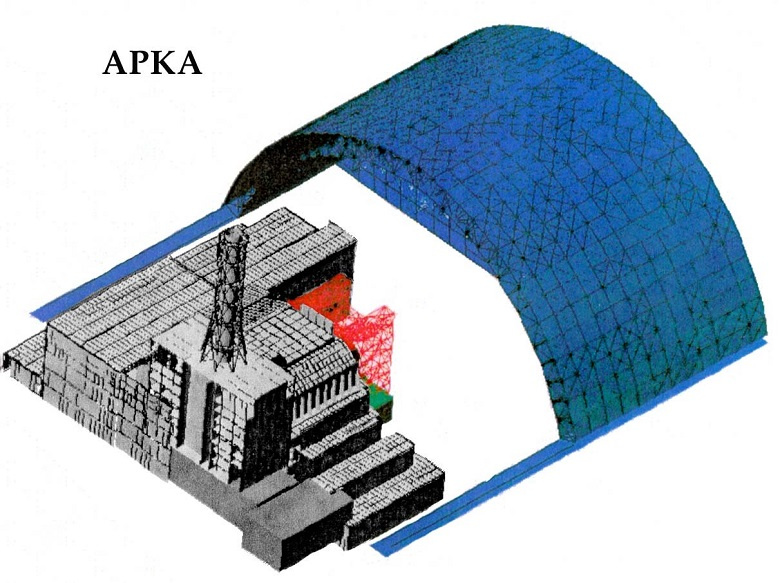

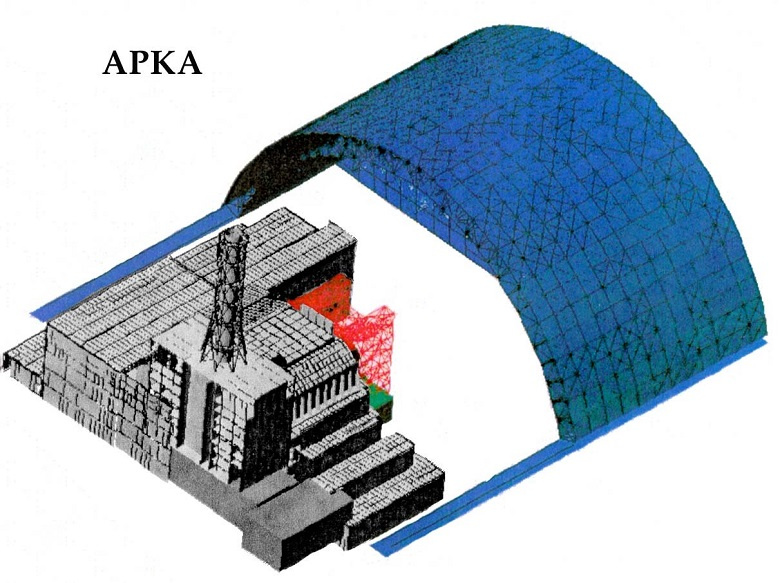

However, arched structures can perform very specific and important tasks. For example, as "Shelter-2", which closed the old crumbling sarcophagus, built over the fourth power unit of the Chernobyl nuclear power plant.

Shelter-2. Scheduled for commissioning in November 2017

This is a grand structure with a width of 257 m and a height of 110 m, weighing 36.2 thousand tons, moreover, is mobile.

New sarcophagus of the Chernobyl nuclear power plant. Design - 2016.

Rather, it was. After completion of the installation, the Shelter-2 was rolled onto the ChNPP building with an emergency reactor.

At the time of construction, Shelter-2 was the largest mobile ground structure. In the photo - part of the team of builders - French companies Bouygues and Vinci. A source

Another - not a gloomy, but a positive example of the functional use of arched structures - the Sydney Opera House. The roof in the form of shells, sails (and in fact orange peel), invented and embodied in concrete by the Danish Jorn Utzon is known to the whole world. The shells are made of precast concrete panels in the shape of a triangle, which are supported by 32 precast concrete ribs.

The structure weighing more than 26,700 tons is held by steel cables with a total length of 350 km.

Arches of Sydney Opera. And the roof is good, and tourists like

Lakhta Center also has its own planned - Arch of the main entrance. It will be like in Sydney Opera - big, beautiful and at the same time functional.

About the functionality and the internal space of the arch building, the designers say this:

Inside the main entrance arch - visualization.

In fact, the arch is a large, separate hall through which the main access to the skyscraper and other zones of the complex opens. A separate entrance building in the form of an arch has never been done before.

In the design documentation, the appearance of the structure is described as:

True to the conversation, the architects themselves prefer to use a more poetic description:

We estimate the similarity:

Arch outside

From a different angle:

Seem to be?

But the arch is interesting not so much by ornithological allusions as by solving a complex engineering puzzle.

What is the arch in terms of constructive.

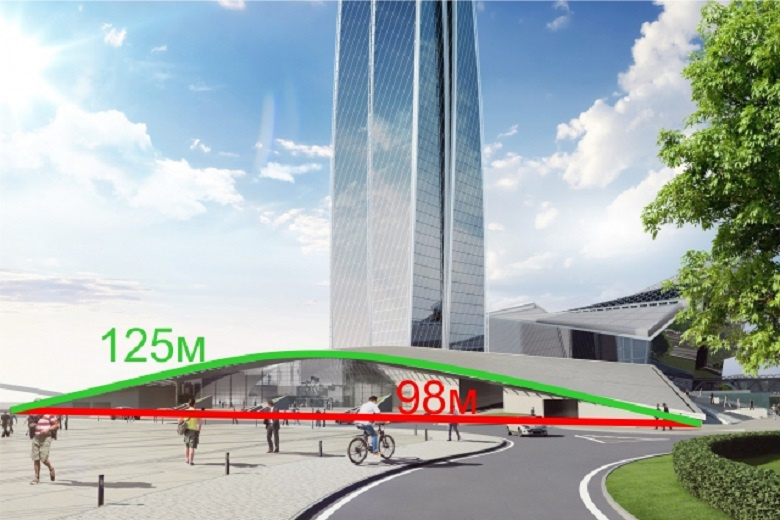

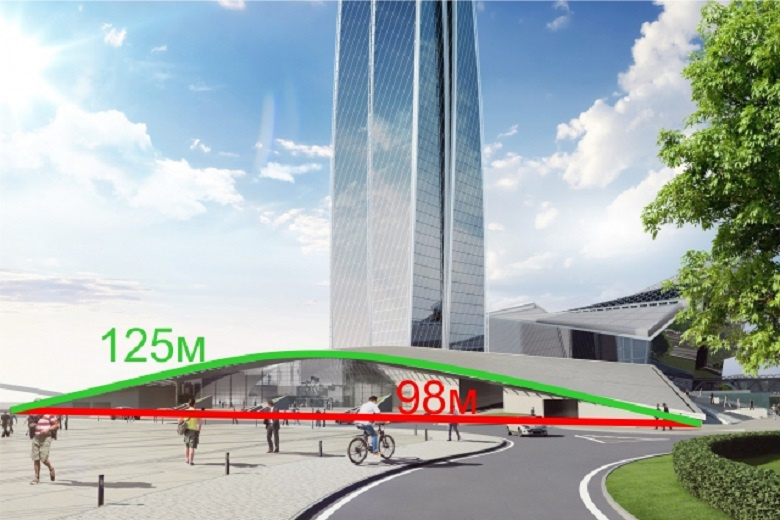

As seen in the visualizations, the construction is of different height. The maximum height of the arch building on the east side is 17.81 m, on the west side - 23.8 m from the zero mark. According to the projection, the span exceeds 125 m, but the more common principle of calculation - according to the vanishing points of the axes - is 98 m.

The main thing is that there is no intermediate support. This is unexpected even by modern architectural standards.

The soaring bridge in Zaryadye. A direct comparison, of course, is not correct - just as an illustration of a modern, unsupported, long-span structure. Here the unsupported departure of the console is 70 meters and this is a lot - the Moscow mayor's office wants to register a Guinness record. PS Someone was at the opening of the bridge? Share your impressions?

But back to Lakhta. Such a large, unsupported part provides the building with the necessary lightness, but at the same time it creates basic difficulties during its implementation.

The main bearing structures are four arches with different lifting booms, different in shape and configuration. Two of them are triangular rectilinear spatial trusses, another one is a composite construction from a planar rectilinear truss, to which two planar elements of smaller size are connected. The most complex element is a spatial truss, which also represents a triangle in section, but, moreover, is curved and inclined.

The construct is a combination of spatial and flat arched trusses.

All arched trusses are assembled from cold-bent steel pipes, which the manufacturer, CIMOLAI, attaches to the necessary shape at its factory in Italy, and then sends them to Chelyabinsk, where another CIMOLAI enterprise assembles shipping sections from them. Each arch consists of nine such sections, which are delivered from the Ural to the Neva on low-frame trawls.

At the factory

Transportation of the shipping section on the trawl

Arrived at the site!

Scale

The shipping section is only one of the nine segments of only one arched arc.

At the construction site, mounting elements are formed of mounting elements - three for each arch (two supporting and one bottomhole). These elements alternately rise to the mounting level. At first two basic are established, then downhole, supported by special support jacks are joined to them. In principle, the technology is the same as that used in the construction of bridges.

Mounting elements in the case of:

When the sending sections are folded into the mounting elements, the accuracy of the connection of the segments is jeweler. The permissible gap should not exceed 0.1 mm. In order to reach the arch, in fact, they are not going to once, but twice. First, a test assembly is carried out at the plant in Chelyabinsk to make sure that all the fixtures hit the right points. Only after this, the farm reassembled to the departure sections is sent to the construction site.

Preliminary assembly - special attention to the connecting nodes

Between the elements connect bolted friction joints. This method is more technological than welding - it is only necessary to clean the joining surfaces well and tighten the bolts with a precisely calculated force using a torque wrench. The result is an absolutely rigid assembly - after tightening the bolts do not experience alternating stress, bending and destructive actions - the force smoothly flows to the mounting plates due to the friction force.

Elements of a frictional coupling connection

Different forces will act on the arch, which can destroy the structure.

In order to cope with the spacer forces acting on the distribution beams, the designers used a very interesting method. The arch has no classical foundation for a complex with piles in the ground. The beams are integrated into the overlap of the underground parking floor.

Reinforcement of reinforced concrete slabs. Immediately, the channel builders, which will be discussed now, are arranged.

The vertical component of the impact force on the supports is successfully perceived by three-meter beams.

With the horizontal component, "pushing" the supporting parts of the arch in this case is more difficult to handle. Exit found in the technology of cable-stayed bridges.

In the slab laid 14 sleeves channel formers, each of which contains 10 high-strength steel ropes with a diameter of 12.5 mm.

Pipeline close-up. They lay steel ropes

With the help of special devices, these ropes are tightened, compensating for the pushing force.

If it’s very simplistic, it’s like a bow strung out, where the shoulders are moving along the arch supporting parts, and the bowstring is the ropes

Before the installation of metal structures, the tension of the ropes is only 50% of the worker - otherwise the force of the impact of the compensating cables themselves will be destructive for overlapping. After installation, the arch's own weight compensates for the tension of the ropes, after which the force is measured and brought to the design, designed to compensate not only for the static impact of the arch, but also for the additional forces that appear due to external influences, such as rain, snow.

After that, a special solution is pumped into the channel-former, transforming the rope bundles into a monolithic cable. To control the force during the operation of the building, strain gauges are installed in the tension nodes and in the pipe former, the information from which is transmitted to the general monitoring system of the Lakhta Center.

All the arches on each side come on a single support leg, while the supporting elements of the arches are not fixed rigidly, but in a fixed-hinged way, the human joint would be the best analogy to the supporting nodes (large plates fixed on the floor). In fact, the arch only rests on the supporting nodes, held in them only at the expense of its own weight. The fact is that the arch itself is quite mobile, its elements “play”, move due to external influence - wind, temperature difference. If it is firmly fixed on the base, in the end, the supporting elements will simply break.

Knots support plates:

For the same basic reason, until the very end of the arch installation, the 1.5 m expansion joint between the stylobate plate and the base of the arch is not poured so that the deformations that occur during the tension of the cables are not transferred to the rest of the structure.

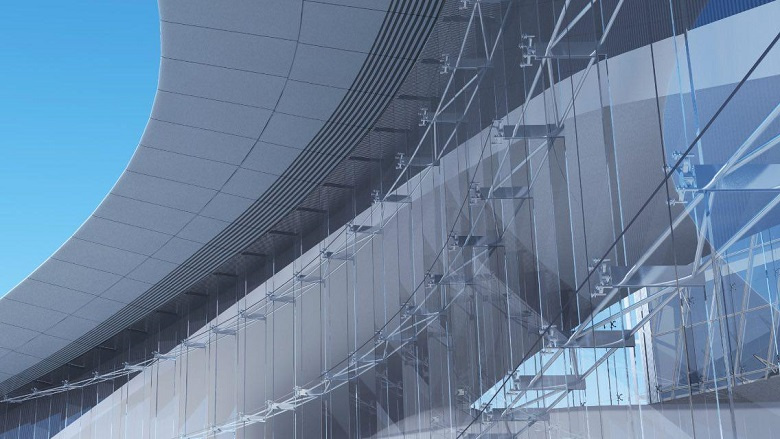

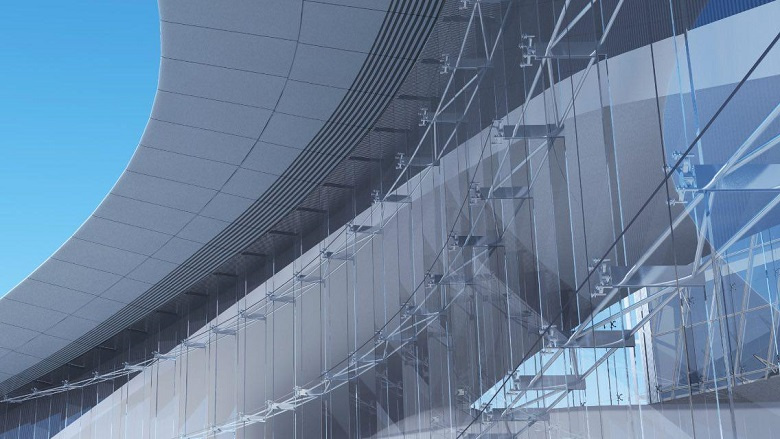

In order to protect the elements of the facade from moving the arch, while ensuring their tightness, special components were designed. And these movements are quite serious. For example, the deflection is of the order of 100-150 mm, which requires compensation for the damaging effects, given that the facade will be completely glass. Completely is not an exaggeration. Even 27-meter vertical posts will be made of glass, on which they fasten the elements of the facade.

Glass racks, which fix the facade elements of the arch. Visualization

General view of the glass facade of the arch - so far too on the visualization

All these technological difficulties - again I quote the project documentation: "due to the architectural ideology of the object." That is, just to be beautiful. Surely it will. But builders will have to work very quickly. According to the regulations, the assembly of the arch structure can be carried out in the temperature range from 0 ° C to 20 ° C. Otherwise, to compensate for thermal deformations, it will be necessary to carry out large-scale calculations just in order not to overtighten or not tighten the bolts.

In the construction of the Arch of the main entrance helped to understand the construction control engineer Igor Romanenko

The winter is coming. It is important to make it to her.

The arch of the main entrance itself is interesting not only by this fact. I do not want to use the description already wiped in relation to Lakhta Center - “a unique construction”, but there is no way out. The entrance to the complex is a unique design.

Firstly, because the unsupported span of the arch is 125 meters. At the same time, the generally accepted point of reference for the uniqueness of large-span and unsupported is “only” 60 meters.

Secondly - the functionality of the arch: this is the entrance to the tower, but made in the form of a separate building.

Why did they do that? How will this long-span magnificence hold on? Why keep up before the cold? All answers - under the cut.

Visualization of the Arch of the main entrance to Lakhta Center

Natural arch vs man-made

The arch is perhaps one of the most monumental architectural elements and, of course, the stingy definition “curvilinear overlapping of the aperture between two supports” does not convey its essence.

Modern architecture is the most complex area in which science and art are harmoniously combined. The most ambitious architectural solutions - akin to launching a rocket into space: the most accurate mathematical calculations, plus the subtlest understanding of the laws of physics and the ability to use them to their advantage. But at the same time, objectively, most of these decisions are an attempt to repeat, and ultimately surpass the creations of the greatest architect, nature. This fully applies to the arched structures. Just look at the largest natural arch in the world - the Fay Xiangren Bridge in northwest China with a 120-meter span.

Fei Xiangren, China

Or the world's oldest Landscape Arch at Arches National Park in Utah. The span is also rather big - 63 m, and in the thinnest part the width of the arch does not exceed 2 m.

Landscape Arch, USA

Of course, the “Gateway of the West” arch in St. Louis (Missouri, USA) is a larger facility (192 m at the top and 192 m wide at the base is a world record) and geometrically adjusted. But there are no fundamental differences from natural arches.

"Gateway of the West", USA, 1965

The most famous in the world, of course, is the “Triumphal Arch” on Charles de Gaulle Square in Paris, erected by architect Jean Shalgren in 1806–36 in commemoration of the victories of the Napoleonic army. Perhaps it is this image that occurs in the thoughts of most people in the world with the word “arch”.

Arc de Triomphe, Paris, 1836

Although Muscovites will probably present the Triumphal Gate on Kutuzovsky,

Triumphal Gate, Moscow. Copy, 1968. The original was erected on the square of the Tverskaya gates in 1829-1834, dismantled in 1936.

Petersburgers - Narva Gates.

Narva Triumphal Gate, St. Petersburg, 1834

All these structures are impressive, beautiful, but perform primarily a decorative function. Even despite the observation deck, located at the top of the "Gateway of the West" or small museums in the interior of the Paris Arc de Triomphe or the St. Petersburg Narva Gate, these objects are difficult to call functional.

Arch decorative vs functional

However, arched structures can perform very specific and important tasks. For example, as "Shelter-2", which closed the old crumbling sarcophagus, built over the fourth power unit of the Chernobyl nuclear power plant.

Shelter-2. Scheduled for commissioning in November 2017

This is a grand structure with a width of 257 m and a height of 110 m, weighing 36.2 thousand tons, moreover, is mobile.

New sarcophagus of the Chernobyl nuclear power plant. Design - 2016.

Rather, it was. After completion of the installation, the Shelter-2 was rolled onto the ChNPP building with an emergency reactor.

At the time of construction, Shelter-2 was the largest mobile ground structure. In the photo - part of the team of builders - French companies Bouygues and Vinci. A source

Another - not a gloomy, but a positive example of the functional use of arched structures - the Sydney Opera House. The roof in the form of shells, sails (and in fact orange peel), invented and embodied in concrete by the Danish Jorn Utzon is known to the whole world. The shells are made of precast concrete panels in the shape of a triangle, which are supported by 32 precast concrete ribs.

The structure weighing more than 26,700 tons is held by steel cables with a total length of 350 km.

Arches of Sydney Opera. And the roof is good, and tourists like

Lakhta Center also has its own planned - Arch of the main entrance. It will be like in Sydney Opera - big, beautiful and at the same time functional.

About the functionality and the internal space of the arch building, the designers say this:

"... In its volume the central place is occupied by a snow-white ramp, one turn raising to the cantilever level where the cafe is located and the exit to the square in front of the Tower. The lower level of the Arch occupies a spacious lobby with a reception desk in the main lobby of the Tower ... "

Inside the main entrance arch - visualization.

In fact, the arch is a large, separate hall through which the main access to the skyscraper and other zones of the complex opens. A separate entrance building in the form of an arch has never been done before.

In the design documentation, the appearance of the structure is described as:

"... The main entrance arch has a complex asymmetrical geometric surface of double positive curvature in the form of a truncated cone side surface. The projection of the roof on a horizontal plane has the shape of a curved sickle-shaped trapezium ..".

True to the conversation, the architects themselves prefer to use a more poetic description:

"... The arch resembles a bent swan, which has spread its wings, and, as it were, inviting guests to the Lakhta Center."

We estimate the similarity:

Arch outside

From a different angle:

Seem to be?

But the arch is interesting not so much by ornithological allusions as by solving a complex engineering puzzle.

Technical specifications

What is the arch in terms of constructive.

As seen in the visualizations, the construction is of different height. The maximum height of the arch building on the east side is 17.81 m, on the west side - 23.8 m from the zero mark. According to the projection, the span exceeds 125 m, but the more common principle of calculation - according to the vanishing points of the axes - is 98 m.

The main thing is that there is no intermediate support. This is unexpected even by modern architectural standards.

The soaring bridge in Zaryadye. A direct comparison, of course, is not correct - just as an illustration of a modern, unsupported, long-span structure. Here the unsupported departure of the console is 70 meters and this is a lot - the Moscow mayor's office wants to register a Guinness record. PS Someone was at the opening of the bridge? Share your impressions?

But back to Lakhta. Such a large, unsupported part provides the building with the necessary lightness, but at the same time it creates basic difficulties during its implementation.

Arch construction

The main bearing structures are four arches with different lifting booms, different in shape and configuration. Two of them are triangular rectilinear spatial trusses, another one is a composite construction from a planar rectilinear truss, to which two planar elements of smaller size are connected. The most complex element is a spatial truss, which also represents a triangle in section, but, moreover, is curved and inclined.

The construct is a combination of spatial and flat arched trusses.

Manufacturing and assembly

All arched trusses are assembled from cold-bent steel pipes, which the manufacturer, CIMOLAI, attaches to the necessary shape at its factory in Italy, and then sends them to Chelyabinsk, where another CIMOLAI enterprise assembles shipping sections from them. Each arch consists of nine such sections, which are delivered from the Ural to the Neva on low-frame trawls.

At the factory

Transportation of the shipping section on the trawl

Arrived at the site!

Scale

The shipping section is only one of the nine segments of only one arched arc.

At the construction site, mounting elements are formed of mounting elements - three for each arch (two supporting and one bottomhole). These elements alternately rise to the mounting level. At first two basic are established, then downhole, supported by special support jacks are joined to them. In principle, the technology is the same as that used in the construction of bridges.

Mounting elements in the case of:

When the sending sections are folded into the mounting elements, the accuracy of the connection of the segments is jeweler. The permissible gap should not exceed 0.1 mm. In order to reach the arch, in fact, they are not going to once, but twice. First, a test assembly is carried out at the plant in Chelyabinsk to make sure that all the fixtures hit the right points. Only after this, the farm reassembled to the departure sections is sent to the construction site.

Preliminary assembly - special attention to the connecting nodes

Between the elements connect bolted friction joints. This method is more technological than welding - it is only necessary to clean the joining surfaces well and tighten the bolts with a precisely calculated force using a torque wrench. The result is an absolutely rigid assembly - after tightening the bolts do not experience alternating stress, bending and destructive actions - the force smoothly flows to the mounting plates due to the friction force.

Elements of a frictional coupling connection

Fight against destructive forces

Different forces will act on the arch, which can destroy the structure.

In order to cope with the spacer forces acting on the distribution beams, the designers used a very interesting method. The arch has no classical foundation for a complex with piles in the ground. The beams are integrated into the overlap of the underground parking floor.

Reinforcement of reinforced concrete slabs. Immediately, the channel builders, which will be discussed now, are arranged.

The vertical component of the impact force on the supports is successfully perceived by three-meter beams.

With the horizontal component, "pushing" the supporting parts of the arch in this case is more difficult to handle. Exit found in the technology of cable-stayed bridges.

In the slab laid 14 sleeves channel formers, each of which contains 10 high-strength steel ropes with a diameter of 12.5 mm.

Pipeline close-up. They lay steel ropes

With the help of special devices, these ropes are tightened, compensating for the pushing force.

If it’s very simplistic, it’s like a bow strung out, where the shoulders are moving along the arch supporting parts, and the bowstring is the ropes

Before the installation of metal structures, the tension of the ropes is only 50% of the worker - otherwise the force of the impact of the compensating cables themselves will be destructive for overlapping. After installation, the arch's own weight compensates for the tension of the ropes, after which the force is measured and brought to the design, designed to compensate not only for the static impact of the arch, but also for the additional forces that appear due to external influences, such as rain, snow.

After that, a special solution is pumped into the channel-former, transforming the rope bundles into a monolithic cable. To control the force during the operation of the building, strain gauges are installed in the tension nodes and in the pipe former, the information from which is transmitted to the general monitoring system of the Lakhta Center.

Support point for supportless span

All the arches on each side come on a single support leg, while the supporting elements of the arches are not fixed rigidly, but in a fixed-hinged way, the human joint would be the best analogy to the supporting nodes (large plates fixed on the floor). In fact, the arch only rests on the supporting nodes, held in them only at the expense of its own weight. The fact is that the arch itself is quite mobile, its elements “play”, move due to external influence - wind, temperature difference. If it is firmly fixed on the base, in the end, the supporting elements will simply break.

Knots support plates:

For the same basic reason, until the very end of the arch installation, the 1.5 m expansion joint between the stylobate plate and the base of the arch is not poured so that the deformations that occur during the tension of the cables are not transferred to the rest of the structure.

In order to protect the elements of the facade from moving the arch, while ensuring their tightness, special components were designed. And these movements are quite serious. For example, the deflection is of the order of 100-150 mm, which requires compensation for the damaging effects, given that the facade will be completely glass. Completely is not an exaggeration. Even 27-meter vertical posts will be made of glass, on which they fasten the elements of the facade.

Glass racks, which fix the facade elements of the arch. Visualization

General view of the glass facade of the arch - so far too on the visualization

All these technological difficulties - again I quote the project documentation: "due to the architectural ideology of the object." That is, just to be beautiful. Surely it will. But builders will have to work very quickly. According to the regulations, the assembly of the arch structure can be carried out in the temperature range from 0 ° C to 20 ° C. Otherwise, to compensate for thermal deformations, it will be necessary to carry out large-scale calculations just in order not to overtighten or not tighten the bolts.

In the construction of the Arch of the main entrance helped to understand the construction control engineer Igor Romanenko

All Articles