Nuclear fuel disposal

Spent nuclear fuel (SNF) is one of the unpleasant problems and to some extent a pain point of nuclear energy. Fresh SNF is extremely deadly - standing at a meter from the fuel assembly from a reactor, you risk a lethal dose in 10–20 seconds. The spent 30 years spent spent nuclear fuel becomes less destructive from the point of view of radiation, but its radiotoxicity (ie, toxicity from irradiation of body tissues from the inside) remains quite at the level - a piece of 20-30 mg of spent nuclear fuel is lethal.

The topic of today's post is the geological disposal of spent nuclear fuel. The most advanced project is Finnish, which presumes storage in such wells deep underground

The atomic industry, however, is saved by the relative insignificance of SNF volumes. If a gigawatt coal-fired CHP plant deals with hundreds of thousands of tons of ash per year, then NPPs have only 30 tons of SNF (~ 40 cartridges). Nevertheless, during the operation of 400 units during decades of SNF, quite a lot of accumulated in the world - about 280 thousand tons, hundreds of thousands of fuel assemblies. Of course, for many decades there has been a question “what to do with this SNF” and the same number of answers:

In spite of the obviousness of decision 3, until now no one in the world has dumped spent nuclear fuel on an industrial basis. The reason, it seems to me, is that along with the finality of the burial, comes the end of shifting responsibility for this step. The responsibility here lies primarily in the fact that the repository may turn out to be unreliable, and flow not after 600 thousand years, but after 10 thousand. And it’s not that this would worry the management of such projects much - they are more concerned with the evidence of the unreliability of the repositories even during their lifetime. After all, justification of reliability for hundreds of thousands of years requires extreme extrapolation - from experimental observations of a potential burial site in a couple of decades to, in fact, hundreds of thousands, similarly to corrosion issues. In the last moment, rounding errors in experimental measurements can mean a choice between the results of “project through 5000 years” and “will stand 500000.

The exposition of the site of the Finnish project Onkalo - in the foreground above-ground structures and the entrance to the tunnel is visible. In the background is the Olkiluoto three-unit NPP, which, by the way, has its own underground burial for medium and low level radioactive waste

The second point around which torments revolve with the implementation of final disposal projects is the value of SNF. Potentially, each ton of spent nuclear fuel contains one and a half percent of fissile substances (odd isotopes of plutonium and uranium 235), as well as the order of a kilogram of palladium and ruthenium - precious metals. Today, the extraction of this from SNF does not pay off the fuss with radiochemistry, but for a long time there was a feeling that energy plutonium was still very useful when launching mass CNFC programs.

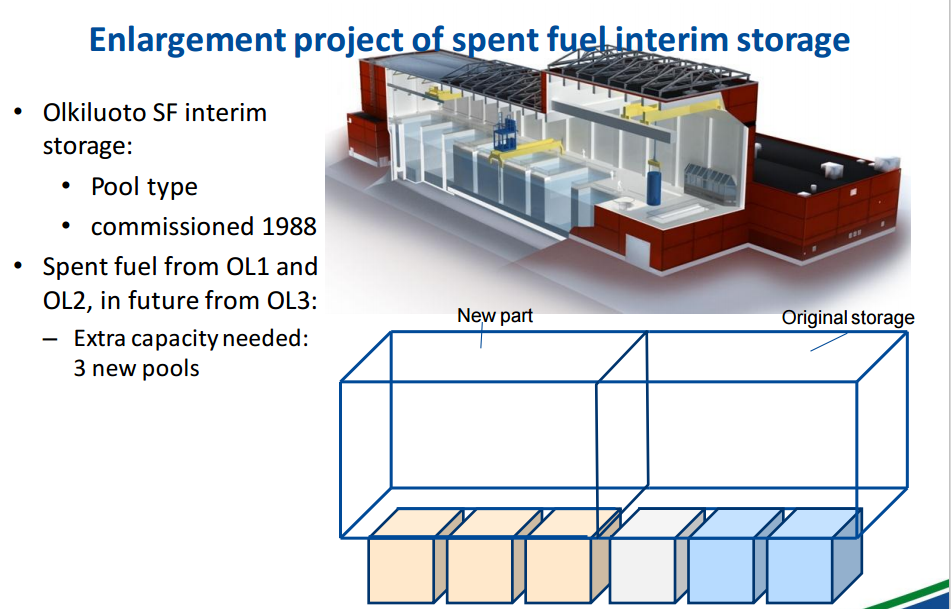

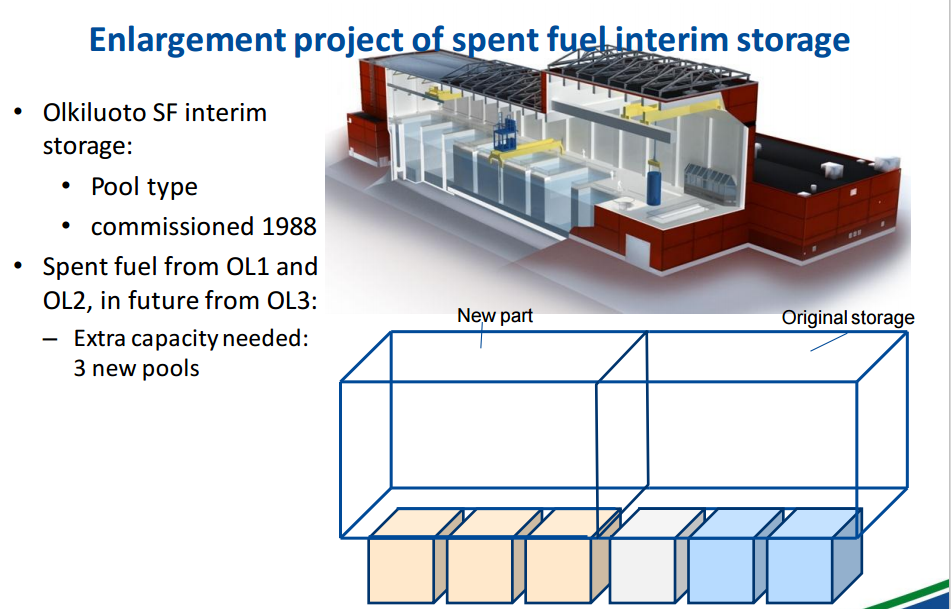

While SNF storage at Finnish NPP Onkalo and Loviisa is carried out in wet storage facilities, as in the picture

In general, today there are two countries that have spat on these throwings and are implementing final geological disposal programs - these are Finland and Sweden and several countries that are seriously investing in the study of specific sites for final disposal of SNF (these are the United States, South Korea, Taiwan and some measure Japan). At the same time, in countries where they are seriously involved in reprocessing spent nuclear fuel (France, Russia, UK) they look closely at the geological disposal of highly active remnants of reprocessing spent nuclear fuel, a technology that, in principle, can be changed into direct disposal of spent nuclear fuel when needed.

After a slightly prolonged preface, I suggest looking at the Finnish approach to burial, implemented by Posiva Oy at the Onkalo site, a couple of kilometers from Olkiluoto NPP.

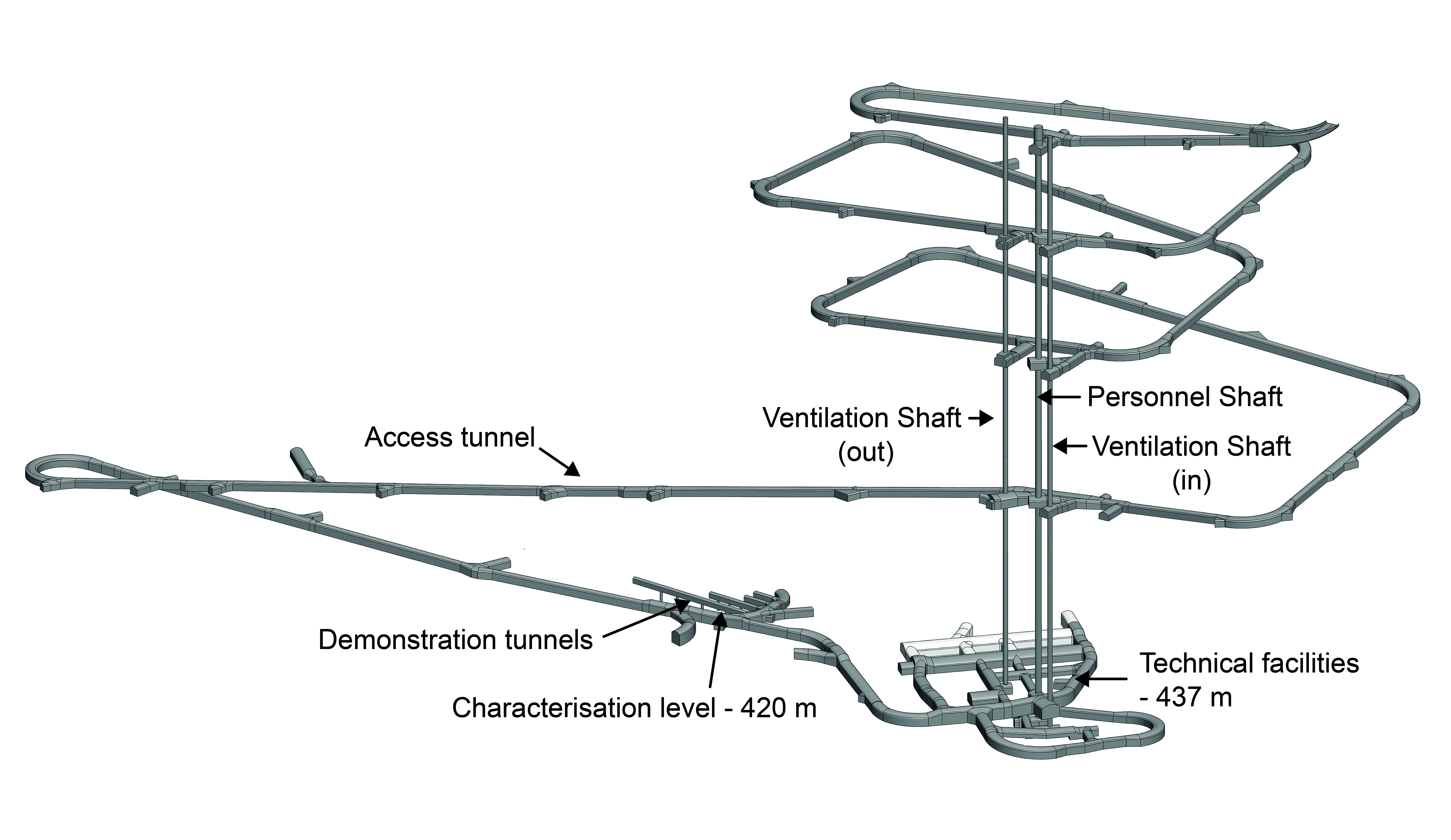

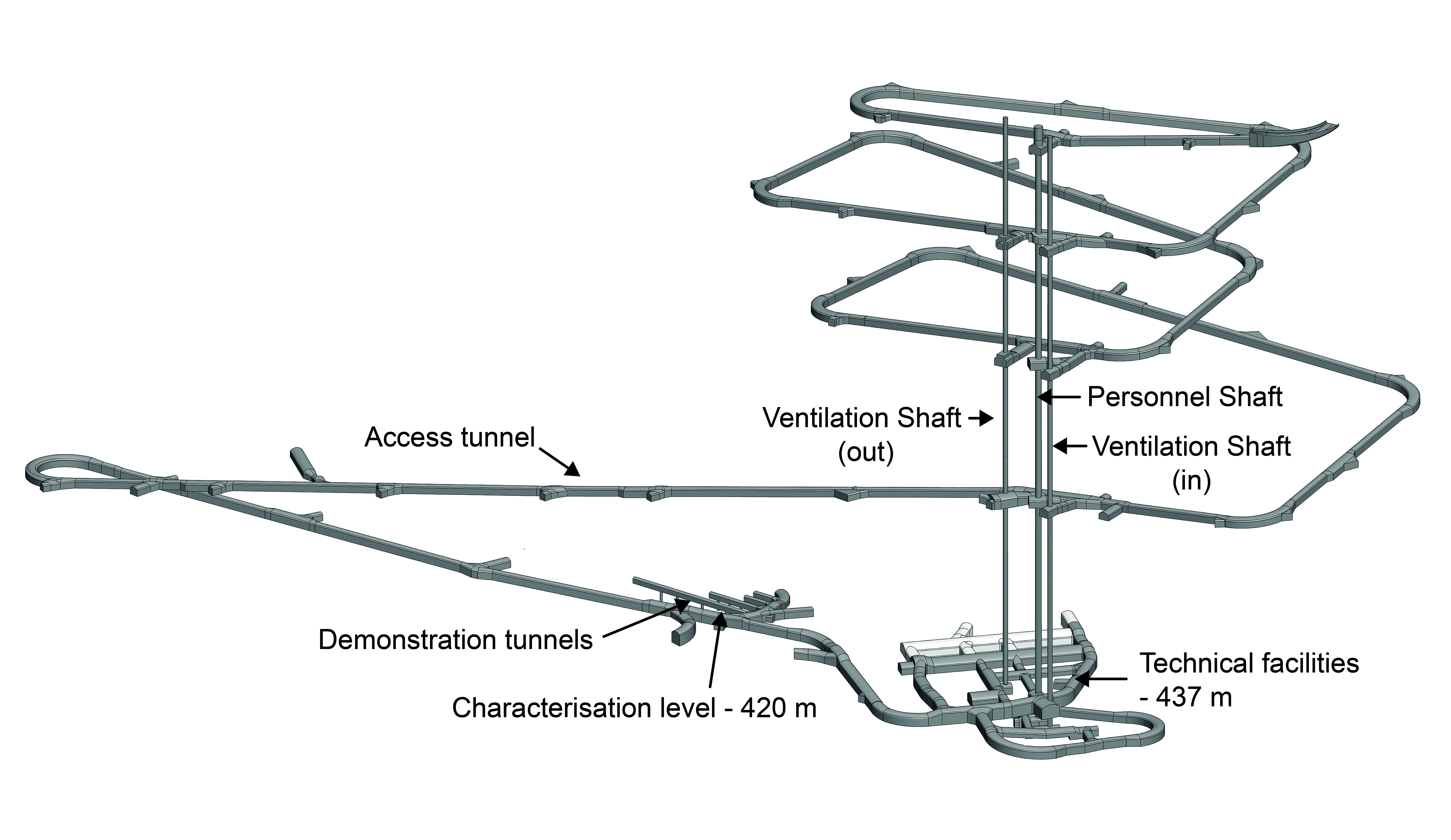

Diagram of the existing underground workings of Onkalo. Approximately from the position of "Technical facilities" tunnels for the placement of SNF will diverge

The burial is supposed to be carried out in a granite massif at a depth of about 420 meters during a project of about a hundred years duration (the beginning of the actual location is 2020e, ending not earlier than 2120), involving the construction of a rather grandiose underground complex. Now the plans are built on existing NPPs, which implies the placement of ~ 2,800 canisters for three types of fuel assemblies (which are in Finland - VVER-440, ASEA BWR and the EPR-1600 that has not yet been commissioned). In principle, the “area” of burial may be enough for all promising nuclear power plants (including Hanhikivi), but so far the volume has been left so.

Onkalo is built by the blasting method. In the frame is just a machine for drilling holes

Fuel assemblies of spent nuclear fuel with a minimum aging period of 20 years will be disposed of, which facilitates work with them. The design work with fuel assemblies looks like this - unloading from a transport container, laying into a vacuum-drying device stored in one canister batch (8 VVER or BWR or 5 EPR-1600), then reloading into the canister. The case is a cast-iron cast construction with grooves for fuel assembly, which is located in a shell of 50 mm copper (which in oxygen-free conditions is the most resistant to long-term corrosion from industrial metals). Next, the canister is evacuated and filled with argon, transported to the station of welding of the lid (copper). The lid is sealed, inspected, after which the canister is ready for burial.

OL-1 type case for storing cassettes from BWR reactors. Copper cover after assembly will be brewed by electron beam welding, robots in vacuum - Finland, as always, is famous for its vacuum, robots and electron beams ...

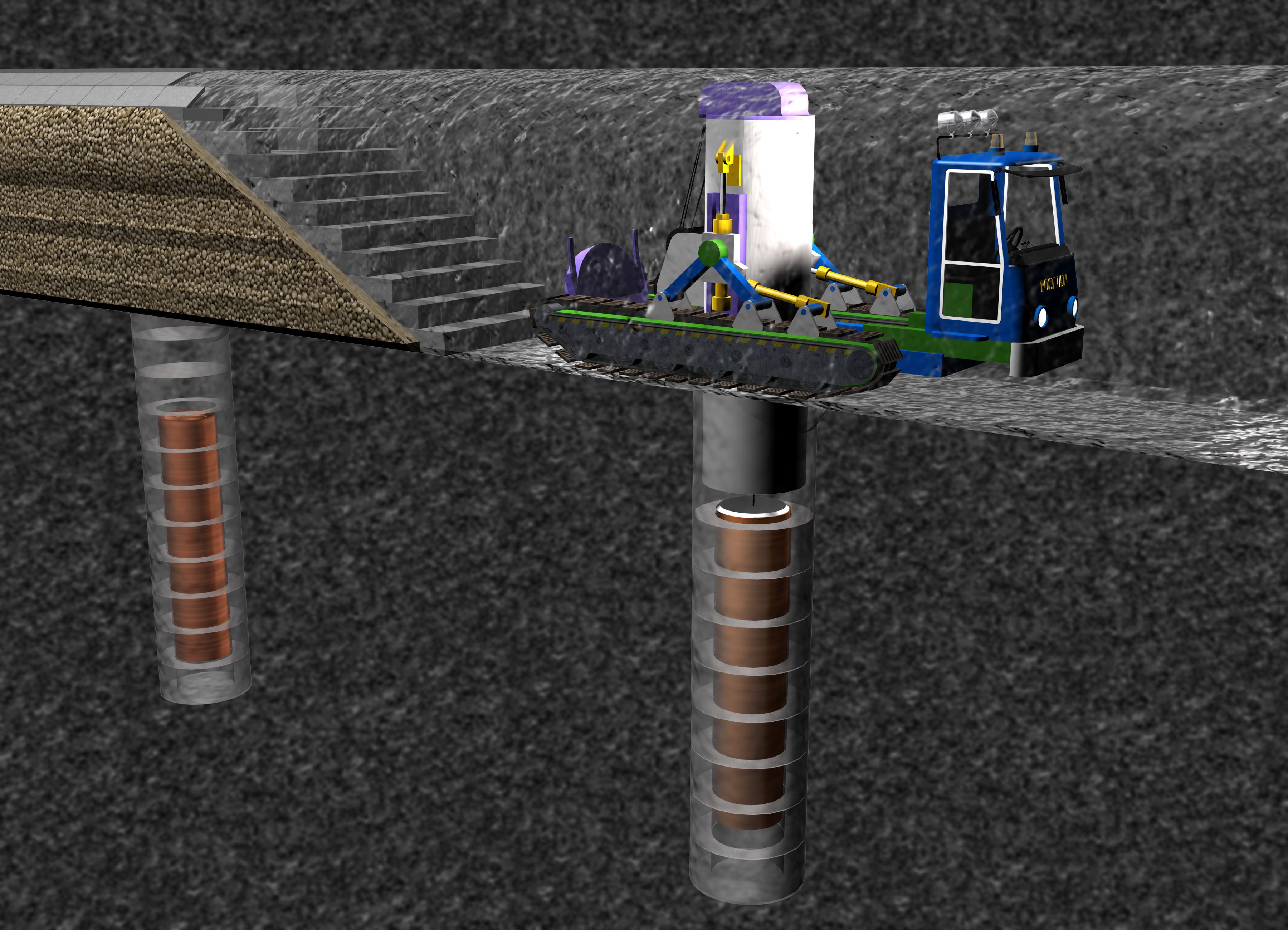

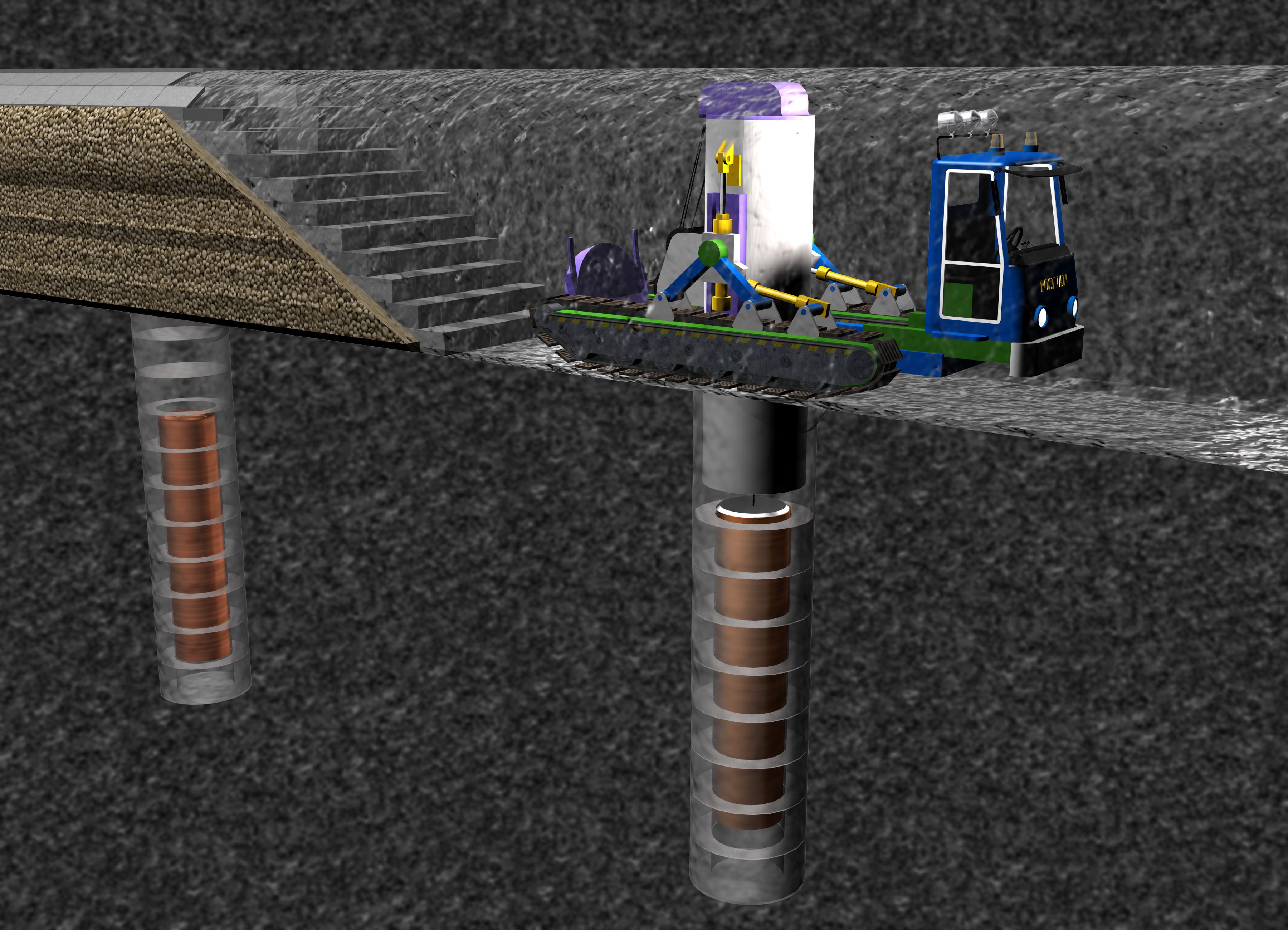

After descending to the burial horizon, the canister is transported to a placement tunnel - measuring 3.5x4 meters, in the floor of which a well of 8 depth and 1.8 meter diameter is drilled every 10 meters. The cases themselves have a diameter of a pig-iron core of 1052 mm, a length of 4 to 6 meters (for different types of fuel assemblies) and a weight of 30-40 tons. The entire space between the canister and the walls of the well is filled with pressed blocks of bentonite (which, as far as you can understand, act as a moisture absorber), and subsequently the tunnel itself must be filled with dry bentonite, and after complete exhaustion of the places at the beginning of the tunnel a large concrete plug is poured.

In general, judging by the thickness of the lid of the canister, the attenuation of gamma-radiation from SNF will not be as great, so the installation of canisters under the ground will be quite difficult with t. engineering task

To move the canisters and bentonite blocks, appropriate underground equipment is being developed.

This video demonstrates how the system installs bentonite plugs. Laser positioning and widespread mechanization suggests that technical requirements for non-proliferation barriers (density and strength, including) are quite complex.

Machine for drilling wells burial.

Currently, the underground infrastructure is almost completed and ready ... by the beginning of the burial experiment - an experimental test of the “burial” procedure will be carried out next year, and then, from 2018 to 2023-27, a controlled experiment will be conducted to measure the real situation around the canister validating all of the safety justifications that Posiva has developed over the past 40 years (yes, that is how many years research has been going on on this topic) and submitted to the Finnish nuclear supervision STUK. If all goes well, an operational license will be obtained and real work will begin to reduce the amount of spent nuclear fuel in Finland.

The planned volumes of lifting workings are impressive.

By the way, the beginning of the 80s to 1996, Finland sent the Loviisa nuclear fuel from the WWER-440 reactors to the USSR / Russia for reprocessing, and as far as I can understand, the HLW from this reprocessing is still stored at Mayak. Then this activity was evaluated by Finami as unprofitable. It is difficult to say how much the processing of HLW at Mayak cost in the 80s, but now they usually operate on figures of 1000-1500 dollars per kg of recycled heavy metals. At the same time, about 150 kg of highly active vitrified waste is obtained from each tonne of SNF, which must also be disposed of.

Onkalo

At the same time, the Onkalo project is currently estimated at 1.1 billion euros (it’s not clear for how long), it is planned to dispose of 1,000 tons of SNF in the very near future and 6,500 tons of everything, which makes costs less than for reprocessing + disposal. There is also an estimate of the total cost of 3.1 billion euros (obviously at current prices) until 2114. The costs will be covered by deductions of Finnish nuclear power plants in the amount of 0.17 cents per kWh (ie, they make up an insignificant part of the selling price of electricity).

Summing up, I would like to say that the start of a real burial (not earlier than 2024, however) can give a tangible impetus to this trend and make it cheaper in the future. This is good, because along with the problematic ZFFC, an alternative, low-cost branch of atomic energy is being built - with uranium mining at sea at a cost of about 300-400 dollars per kg (or rather less in the future) and disposal of SNF as described above - out of mind and out of sight. The cost of such electricity can be comparable to the prospective cost of e / e RES with balancing, while no revolutionary developments will be required.

The topic of today's post is the geological disposal of spent nuclear fuel. The most advanced project is Finnish, which presumes storage in such wells deep underground

The atomic industry, however, is saved by the relative insignificance of SNF volumes. If a gigawatt coal-fired CHP plant deals with hundreds of thousands of tons of ash per year, then NPPs have only 30 tons of SNF (~ 40 cartridges). Nevertheless, during the operation of 400 units during decades of SNF, quite a lot of accumulated in the world - about 280 thousand tons, hundreds of thousands of fuel assemblies. Of course, for many decades there has been a question “what to do with this SNF” and the same number of answers:

- Do nothing, store on the grounds , leave the problem to descendants. Very technologically, conveniently and cheaply, but sometimes morally uncomfortable.

- Recycle . BUT! That is probably the solution to the problem? Not really. In this case, reprocessing is essentially the concentration / sorting of radioactivity of SNF according to the degree of harmfulness, but at the same time the radionuclides themselves do not go anywhere. As a bonus - reduced volumes for burial

- Burial Isolation of spent nuclear fuel under the ground in such a way that over the next 100-500 thousand years it will remain there, without getting into the human world. It is also necessary for option 2, although there are some nuances.

In spite of the obviousness of decision 3, until now no one in the world has dumped spent nuclear fuel on an industrial basis. The reason, it seems to me, is that along with the finality of the burial, comes the end of shifting responsibility for this step. The responsibility here lies primarily in the fact that the repository may turn out to be unreliable, and flow not after 600 thousand years, but after 10 thousand. And it’s not that this would worry the management of such projects much - they are more concerned with the evidence of the unreliability of the repositories even during their lifetime. After all, justification of reliability for hundreds of thousands of years requires extreme extrapolation - from experimental observations of a potential burial site in a couple of decades to, in fact, hundreds of thousands, similarly to corrosion issues. In the last moment, rounding errors in experimental measurements can mean a choice between the results of “project through 5000 years” and “will stand 500000.

The exposition of the site of the Finnish project Onkalo - in the foreground above-ground structures and the entrance to the tunnel is visible. In the background is the Olkiluoto three-unit NPP, which, by the way, has its own underground burial for medium and low level radioactive waste

The second point around which torments revolve with the implementation of final disposal projects is the value of SNF. Potentially, each ton of spent nuclear fuel contains one and a half percent of fissile substances (odd isotopes of plutonium and uranium 235), as well as the order of a kilogram of palladium and ruthenium - precious metals. Today, the extraction of this from SNF does not pay off the fuss with radiochemistry, but for a long time there was a feeling that energy plutonium was still very useful when launching mass CNFC programs.

While SNF storage at Finnish NPP Onkalo and Loviisa is carried out in wet storage facilities, as in the picture

In general, today there are two countries that have spat on these throwings and are implementing final geological disposal programs - these are Finland and Sweden and several countries that are seriously investing in the study of specific sites for final disposal of SNF (these are the United States, South Korea, Taiwan and some measure Japan). At the same time, in countries where they are seriously involved in reprocessing spent nuclear fuel (France, Russia, UK) they look closely at the geological disposal of highly active remnants of reprocessing spent nuclear fuel, a technology that, in principle, can be changed into direct disposal of spent nuclear fuel when needed.

After a slightly prolonged preface, I suggest looking at the Finnish approach to burial, implemented by Posiva Oy at the Onkalo site, a couple of kilometers from Olkiluoto NPP.

Diagram of the existing underground workings of Onkalo. Approximately from the position of "Technical facilities" tunnels for the placement of SNF will diverge

The burial is supposed to be carried out in a granite massif at a depth of about 420 meters during a project of about a hundred years duration (the beginning of the actual location is 2020e, ending not earlier than 2120), involving the construction of a rather grandiose underground complex. Now the plans are built on existing NPPs, which implies the placement of ~ 2,800 canisters for three types of fuel assemblies (which are in Finland - VVER-440, ASEA BWR and the EPR-1600 that has not yet been commissioned). In principle, the “area” of burial may be enough for all promising nuclear power plants (including Hanhikivi), but so far the volume has been left so.

Onkalo is built by the blasting method. In the frame is just a machine for drilling holes

Fuel assemblies of spent nuclear fuel with a minimum aging period of 20 years will be disposed of, which facilitates work with them. The design work with fuel assemblies looks like this - unloading from a transport container, laying into a vacuum-drying device stored in one canister batch (8 VVER or BWR or 5 EPR-1600), then reloading into the canister. The case is a cast-iron cast construction with grooves for fuel assembly, which is located in a shell of 50 mm copper (which in oxygen-free conditions is the most resistant to long-term corrosion from industrial metals). Next, the canister is evacuated and filled with argon, transported to the station of welding of the lid (copper). The lid is sealed, inspected, after which the canister is ready for burial.

OL-1 type case for storing cassettes from BWR reactors. Copper cover after assembly will be brewed by electron beam welding, robots in vacuum - Finland, as always, is famous for its vacuum, robots and electron beams ...

After descending to the burial horizon, the canister is transported to a placement tunnel - measuring 3.5x4 meters, in the floor of which a well of 8 depth and 1.8 meter diameter is drilled every 10 meters. The cases themselves have a diameter of a pig-iron core of 1052 mm, a length of 4 to 6 meters (for different types of fuel assemblies) and a weight of 30-40 tons. The entire space between the canister and the walls of the well is filled with pressed blocks of bentonite (which, as far as you can understand, act as a moisture absorber), and subsequently the tunnel itself must be filled with dry bentonite, and after complete exhaustion of the places at the beginning of the tunnel a large concrete plug is poured.

In general, judging by the thickness of the lid of the canister, the attenuation of gamma-radiation from SNF will not be as great, so the installation of canisters under the ground will be quite difficult with t. engineering task

To move the canisters and bentonite blocks, appropriate underground equipment is being developed.

This video demonstrates how the system installs bentonite plugs. Laser positioning and widespread mechanization suggests that technical requirements for non-proliferation barriers (density and strength, including) are quite complex.

Machine for drilling wells burial.

Currently, the underground infrastructure is almost completed and ready ... by the beginning of the burial experiment - an experimental test of the “burial” procedure will be carried out next year, and then, from 2018 to 2023-27, a controlled experiment will be conducted to measure the real situation around the canister validating all of the safety justifications that Posiva has developed over the past 40 years (yes, that is how many years research has been going on on this topic) and submitted to the Finnish nuclear supervision STUK. If all goes well, an operational license will be obtained and real work will begin to reduce the amount of spent nuclear fuel in Finland.

The planned volumes of lifting workings are impressive.

By the way, the beginning of the 80s to 1996, Finland sent the Loviisa nuclear fuel from the WWER-440 reactors to the USSR / Russia for reprocessing, and as far as I can understand, the HLW from this reprocessing is still stored at Mayak. Then this activity was evaluated by Finami as unprofitable. It is difficult to say how much the processing of HLW at Mayak cost in the 80s, but now they usually operate on figures of 1000-1500 dollars per kg of recycled heavy metals. At the same time, about 150 kg of highly active vitrified waste is obtained from each tonne of SNF, which must also be disposed of.

Onkalo

At the same time, the Onkalo project is currently estimated at 1.1 billion euros (it’s not clear for how long), it is planned to dispose of 1,000 tons of SNF in the very near future and 6,500 tons of everything, which makes costs less than for reprocessing + disposal. There is also an estimate of the total cost of 3.1 billion euros (obviously at current prices) until 2114. The costs will be covered by deductions of Finnish nuclear power plants in the amount of 0.17 cents per kWh (ie, they make up an insignificant part of the selling price of electricity).

Summing up, I would like to say that the start of a real burial (not earlier than 2024, however) can give a tangible impetus to this trend and make it cheaper in the future. This is good, because along with the problematic ZFFC, an alternative, low-cost branch of atomic energy is being built - with uranium mining at sea at a cost of about 300-400 dollars per kg (or rather less in the future) and disposal of SNF as described above - out of mind and out of sight. The cost of such electricity can be comparable to the prospective cost of e / e RES with balancing, while no revolutionary developments will be required.

All Articles