[CASE] How we made a copy of the Worker and Collective Farm Women for the European Parliament Museum

Order

Employees of the Shchusev Moscow Museum of Architecture applied to the Top 3D Shop.

Museum workers came to us with a contract to copy a sculptural composition - a prototype of the monument Worker and Kolkhoz Woman, which was created by sculptor Vera Mukhina.

The original of the sculpture, after which the well-known 24.5-meter steel monument was subsequently created, is located in the museum itself.

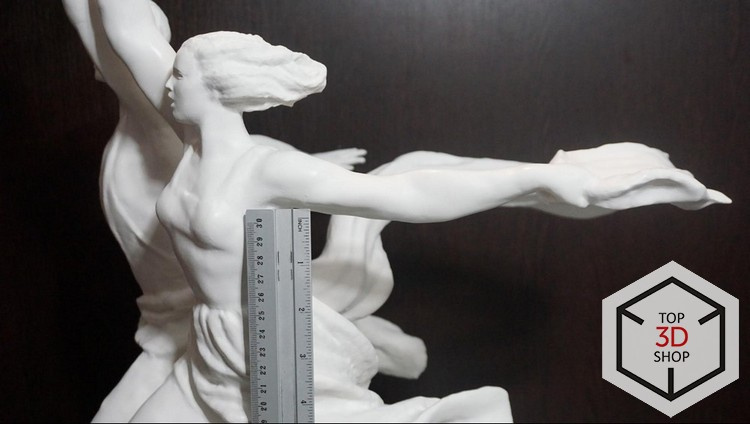

This is a plaster composition with a height of human height. We had to scan this piece of art and print a copy of 33% of the original.

The customer is the House of European History Museum in Brussels, owned by the European Parliament. He collects copies of works of art and monuments related to the history of Europe. We contacted the assistant curator of the museum, clarified the details and began work.

As it happens

Without the use of 3D scanning and printing, copying would have had to be done for a long time by the sculptor specially hired for this, within the walls of the museum, in direct contact with the original, which is administratively and organizationally very difficult. Obvious disadvantages of this approach: duration, high cost, inaccurate transfer of proportions and forms, in general - the human factor.

How we did it

Scanning

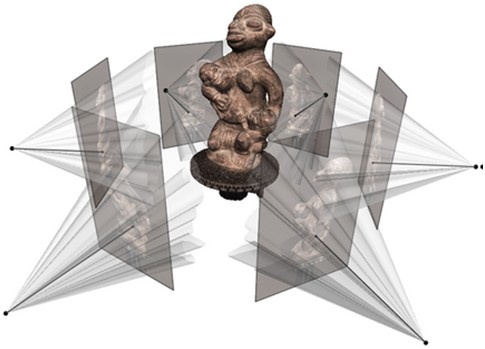

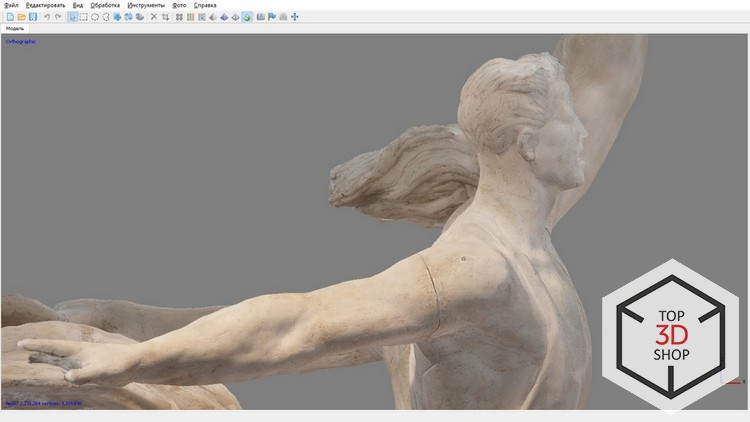

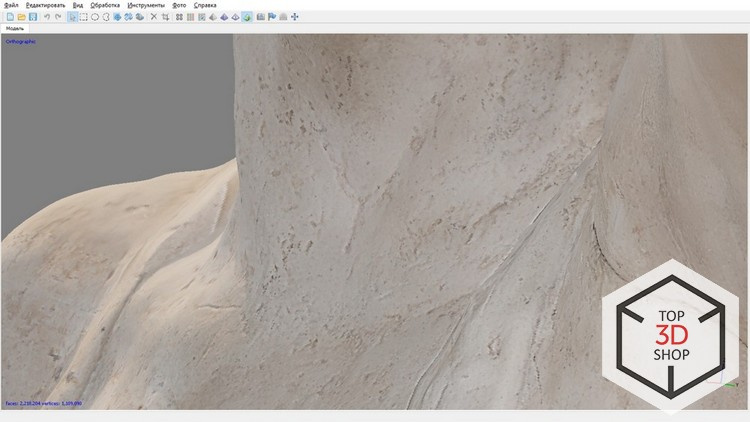

We conducted a detailed photogrammetry of the object - scanning a series of photographs, followed by connection into a three-dimensional digital object. Photogrammetry is performed as follows :

Or so, with multiple cameras at the same time:

In our case, it was one employee with a camera. This scanning technology was chosen for several reasons, such as the absence of the need to cover the scanned object with a matting spray, which would be unacceptable in the case of the original work of art, and the high accuracy of detail transmission.

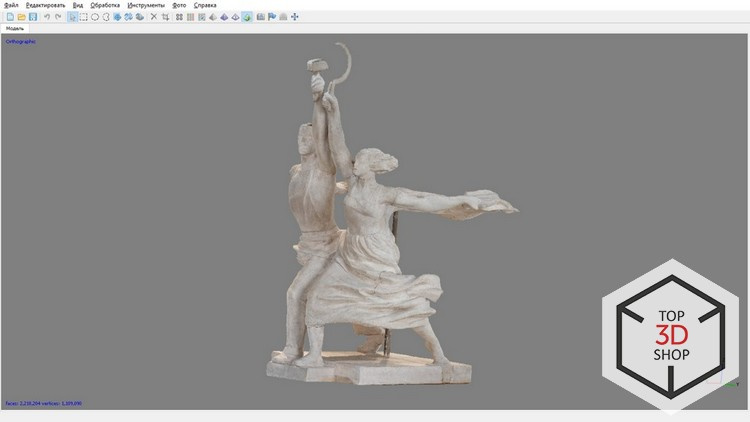

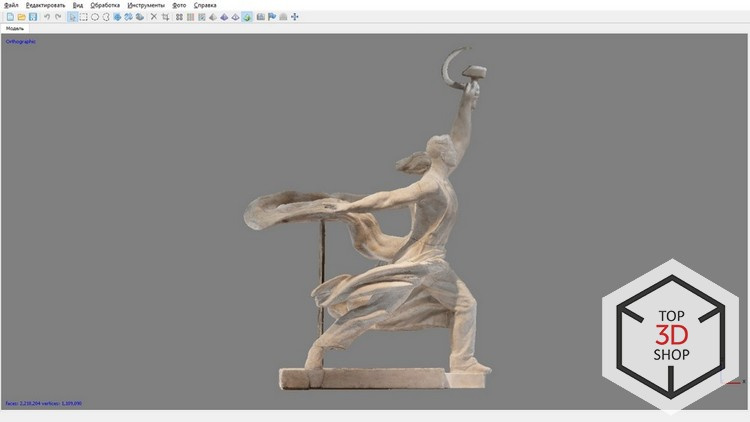

There could be difficulties with the lighting, but the museum staff kindly moved the sculpture to the illuminated place and we took 400 photographs, which we then programmatically combined into a three-dimensional model.

Scanning took four hours, the subsequent processing of the digital model, gluing, removal of artifacts - another day.

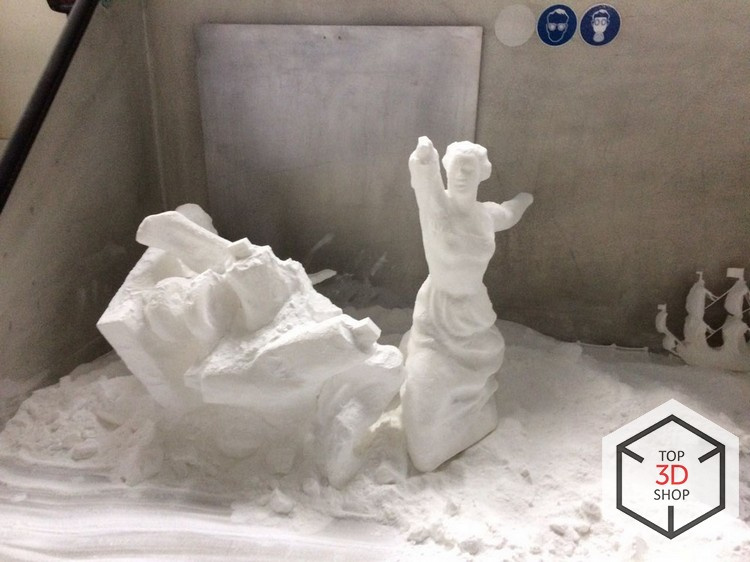

Printed from PA 2200 polyamide, on EOS Formiga 3D printer.

This is a professional 3D printer, working on the technology of selective laser sintering, printing objects with sizes up to 200 x 250 x 330 mm, with a layer thickness of 60 microns and a speed of 20 mm / hour. The printer was chosen for accuracy and speed of work, and the material for external similarity of printouts with the surface of the original.

The polymer powder in the printer is applied in layers, and the laser fuses it into a monolithic structure.

For greater accuracy in the transfer of forms, the model was made composite - separately the platform, the figures of people, the sickle and the hammer.

After printing, the product was assembled, glued together with epoxy.

Then polished.

Painting

Especially for this order, we found professional restorers who painted the model so that the polyamide copy looked like a plaster original, only a new one, acquired only a small gloss. All parts retain the original geometry.

Packaging

After painting, the product was carefully packaged to ensure its safety during shipment.

It takes about a month to make such an order, including scanning, processing a digital model, printing, assembling and painting. The amount of the order can not be called, it is confidential information.

Benefit

In Top 3D Shop you can order an exact copy of any available for scanning or already existing digital sculpture, in order to decorate with it a museum or exhibition exposition, an apartment, a restaurant, a country house or an office. Can use the 3D-technology and sculptors, if they prefer to work with a digital model, rather than manually.

Order 3D scanning and 3D printing of any objects in the Top 3D Shop.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

All Articles