Our metallic. Something curious about the metalwork of Lakhta Center

The Lakhta Center Tower is sometimes compared with the work of bard-Dura architects, widely advertised by J.R.R. Tolkien.

Such a comparison even makes me a little happy - it has a romantic look at building realities. However, the further “legendization” of the skyscraper in this direction will soon become impossible. In the fabulous form, the supermassive core and the hardcore frame made of metals and composites in six months will finally turn into glass and forever disappear from sight.

by boyarskaya_48

In the meantime, our Atlantis has not disappeared, it's time to talk about the metal - an important component of the frame Supertoll.

At the end of June correspondent Anton Ratnikov visited the construction site. Read the material prepared by him specifically for our blog.

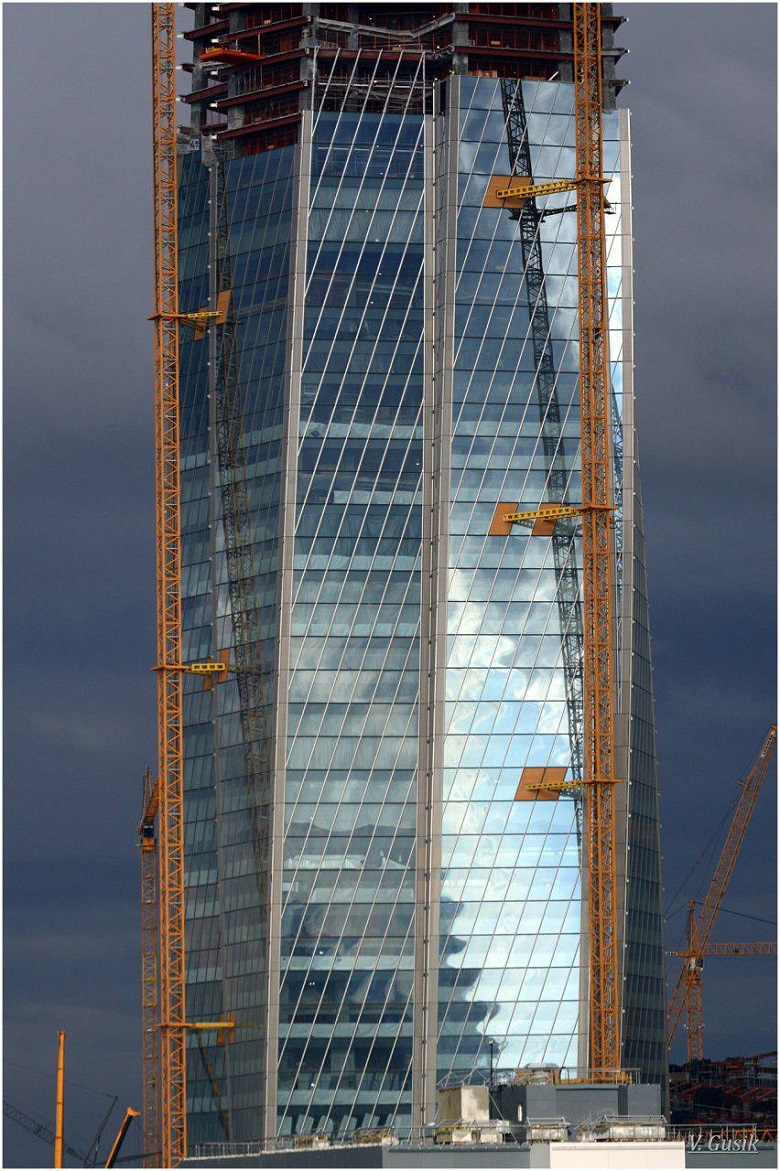

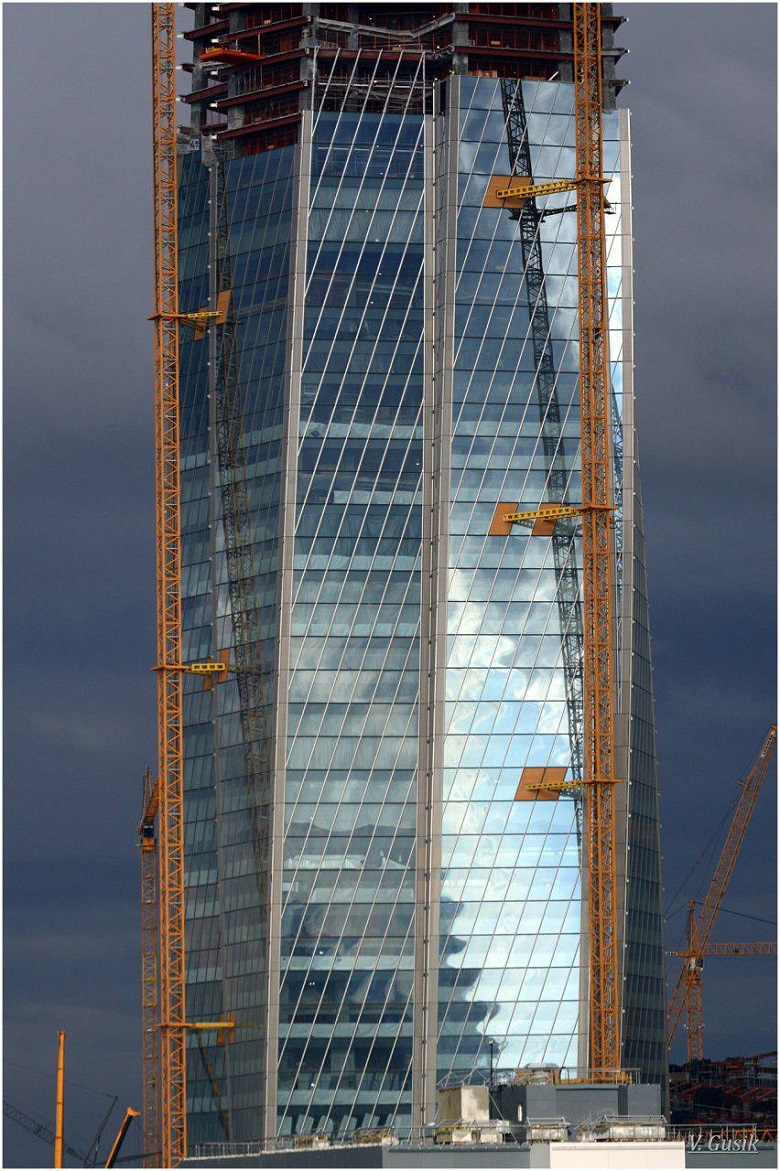

Unusually hot Petersburg day. We are sitting in a temporary building, mounted on the Lakhta Center construction site. In the middle - a round table for meetings. The window shows how the workers are engaged in the glazing of the building. The work goes well. Movement does not stop for a second.

Glazing MFZ

I’ve been watching this scene for a while with construction control engineer Igor Romanenko.

“I didn’t have such a number of metal constructions,” we return to the topic of our meeting, “and I, believe me, built a lot of large-scale projects,” says Igor.

How much metal are we talking about?

On the tower itself you need 22 thousand tons of "with a tail" of metal structures. Another 2 thousand tons will go to the spire. The framing MFZ skyscraper — plus about 24 thousand tons — is an approximate weight of an average ocean cruise liner.

( Photo Source )

If to express tons in pieces, then it is - 189 thousand various metal structures only for the tower.

Not counting hardware!

Bringing such quantities of metal to the site is a logistic task of the 80th level.

- You can imagine, about thirty percent of the structures we delivered to the site as oversized with the support of special services! - says Igor.

Especially builders are proud that while they manage to avoid traffic jams on the Primorskoe highway, which is key for the city. Logistics is calculated by the minute and thought out so that the intervention of tractors in city life was minimal.

Another difficulty is operational storage. A small stock of metal structures is stored on the site. Most need to immediately, "from the wheels", to put into work, otherwise the construction site will turn into an impassable metal forest.

To arrange large warehouses with such a dense building is simply nowhere

You need to act quickly and accurately. Usually it is mutually exclusive concepts. And then there are tens of thousands of parts - just two repetitive.

This is due to the complex tower configuration. Each floor has its own area - either wider or previous. Therefore, metal structures at each level have their own specific features.

The tower expands to the 16th floor. then tapers, plus - torsion. Photo - Victor Gusik

So how do you manage to assemble the metal frame quickly and without errors?

In fact, Lakhta Center is a huge metal 3D puzzle. Only if, when collecting a model at home, you can take a break, drink coffee, or just start all over again, is there no right to carelessness.

The secret of the assembly is that every detail has been equipped with a barcode. The data is entered into a common online database. Everyone at the site can see which construction is where at each moment in time. Conveniently? Conveniently!

“If this system did not exist, it would be impossible to work,” Romanenko says.

By the way, as a result, the developer convinced the plants to introduce this system at the production stage. And the plants liked it. Some even decided to apply it in the subsequent work. We met new technologies.

Metal structures for Lakhta Center are made at twelve factories. This is perhaps a record. Of the twelve industries - ten Russian.

“All large factories are working on our construction site,” says Igor.

Even at the production stage, all the structures, like astronauts, are tested directly at the plants before the flight into space. And that only do not do with them. Only if the centrifuge is not squeezed.

Designers and engineering company of the project are also details from and to. As a result, you can avoid marriage.

Another miracle - the columns around the perimeter of the building. In the construction used technology of composite columns - reinforced concrete with steel core. From the point of view of builders, "a work of art." And it is true. If you look at the column in cross section - you will find that you see the Maltese cross. She has such an elegant form.

Sometimes the words of Igor Romanenko about these metal structures even resemble poetry.

“Our column has a bend, a torsion, a moment, and a compression ...” he almost recites.

Yes, each column has a slope and turn. The deviation for each is 2.89 degrees for each section. This is how the unusual twisting effect takes place, which today is already clearly visible.

“Composite columns are a joint work of two materials: metal and concrete,” Romanenko continues the story. - In general, we are the first civil construction in Russia, where such technology is used. Previously, such standards simply did not exist. The designers had to coordinate all this in the relevant ministries. And now the composite columns can be built by those who follow us. Roughly speaking, we pushed the forest ...

The last columns are going to be installed closer to the end of the summer. Then go to the spire. That, which in the future can compete with the main spire of St. Petersburg - in Petropavlovka.

The spire will be 92 meters high and weigh two thousand tons. Unlike the main building, there will be no core inside - the structure is hollow. The design decision is such that from the side of the spire it will seem like a continuation of the glass facade. From the ground you will not notice where one ends and the other begins. And the top of the spire will often be hidden behind the usual Petersburg clouds.

Igor Romanenko finally says:

- I sometimes get funny questions. Well, for example, what will happen if all the people in the tower gather on one side of it: Will it really tilt? I just laugh back. Nothing will happen to her. The design is super reliable. And unique to the country.

Igor Romanenko was telling - Lakhta Center construction control engineer.

Anton Ratnikov visited the site.

-

Photo news can be viewed on our Telegram channel .

Such a comparison even makes me a little happy - it has a romantic look at building realities. However, the further “legendization” of the skyscraper in this direction will soon become impossible. In the fabulous form, the supermassive core and the hardcore frame made of metals and composites in six months will finally turn into glass and forever disappear from sight.

by boyarskaya_48

In the meantime, our Atlantis has not disappeared, it's time to talk about the metal - an important component of the frame Supertoll.

At the end of June correspondent Anton Ratnikov visited the construction site. Read the material prepared by him specifically for our blog.

SO MANY METAL WERE NOT

Unusually hot Petersburg day. We are sitting in a temporary building, mounted on the Lakhta Center construction site. In the middle - a round table for meetings. The window shows how the workers are engaged in the glazing of the building. The work goes well. Movement does not stop for a second.

Glazing MFZ

I’ve been watching this scene for a while with construction control engineer Igor Romanenko.

“I didn’t have such a number of metal constructions,” we return to the topic of our meeting, “and I, believe me, built a lot of large-scale projects,” says Igor.

How much metal are we talking about?

On the tower itself you need 22 thousand tons of "with a tail" of metal structures. Another 2 thousand tons will go to the spire. The framing MFZ skyscraper — plus about 24 thousand tons — is an approximate weight of an average ocean cruise liner.

( Photo Source )

LOGS 80-LEVEL

If to express tons in pieces, then it is - 189 thousand various metal structures only for the tower.

Not counting hardware!

Bringing such quantities of metal to the site is a logistic task of the 80th level.

- You can imagine, about thirty percent of the structures we delivered to the site as oversized with the support of special services! - says Igor.

Especially builders are proud that while they manage to avoid traffic jams on the Primorskoe highway, which is key for the city. Logistics is calculated by the minute and thought out so that the intervention of tractors in city life was minimal.

Another difficulty is operational storage. A small stock of metal structures is stored on the site. Most need to immediately, "from the wheels", to put into work, otherwise the construction site will turn into an impassable metal forest.

To arrange large warehouses with such a dense building is simply nowhere

You need to act quickly and accurately. Usually it is mutually exclusive concepts. And then there are tens of thousands of parts - just two repetitive.

This is due to the complex tower configuration. Each floor has its own area - either wider or previous. Therefore, metal structures at each level have their own specific features.

The tower expands to the 16th floor. then tapers, plus - torsion. Photo - Victor Gusik

So how do you manage to assemble the metal frame quickly and without errors?

PUZZLE HIGH IN 462 METERS

In fact, Lakhta Center is a huge metal 3D puzzle. Only if, when collecting a model at home, you can take a break, drink coffee, or just start all over again, is there no right to carelessness.

The secret of the assembly is that every detail has been equipped with a barcode. The data is entered into a common online database. Everyone at the site can see which construction is where at each moment in time. Conveniently? Conveniently!

“If this system did not exist, it would be impossible to work,” Romanenko says.

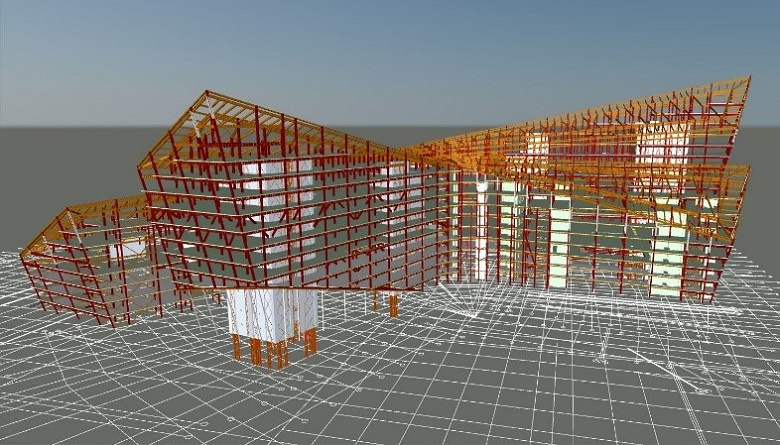

This labeling system is based on BIM technology - an intelligent building model that combines all project documentation with changes over time.

BIM-model of MFZ Lakhta Center

By the way, as a result, the developer convinced the plants to introduce this system at the production stage. And the plants liked it. Some even decided to apply it in the subsequent work. We met new technologies.

HOW STEEL GOT

Metal structures for Lakhta Center are made at twelve factories. This is perhaps a record. Of the twelve industries - ten Russian.

“All large factories are working on our construction site,” says Igor.

Even at the production stage, all the structures, like astronauts, are tested directly at the plants before the flight into space. And that only do not do with them. Only if the centrifuge is not squeezed.

Designers and engineering company of the project are also details from and to. As a result, you can avoid marriage.

METAL POETRY

Another miracle - the columns around the perimeter of the building. In the construction used technology of composite columns - reinforced concrete with steel core. From the point of view of builders, "a work of art." And it is true. If you look at the column in cross section - you will find that you see the Maltese cross. She has such an elegant form.

The form of the Maltese cross is formed by two I-profiles welded together. I-beam - a historic element. It originated from the development of a rail rail form and became the first standardized building element.

Sometimes the words of Igor Romanenko about these metal structures even resemble poetry.

“Our column has a bend, a torsion, a moment, and a compression ...” he almost recites.

Yes, each column has a slope and turn. The deviation for each is 2.89 degrees for each section. This is how the unusual twisting effect takes place, which today is already clearly visible.

“Composite columns are a joint work of two materials: metal and concrete,” Romanenko continues the story. - In general, we are the first civil construction in Russia, where such technology is used. Previously, such standards simply did not exist. The designers had to coordinate all this in the relevant ministries. And now the composite columns can be built by those who follow us. Roughly speaking, we pushed the forest ...

WHAT WILL BE IF IF EVERYONE COLLATES ON ONE SIDE OF THE TOWER

The last columns are going to be installed closer to the end of the summer. Then go to the spire. That, which in the future can compete with the main spire of St. Petersburg - in Petropavlovka.

The spire will be 92 meters high and weigh two thousand tons. Unlike the main building, there will be no core inside - the structure is hollow. The design decision is such that from the side of the spire it will seem like a continuation of the glass facade. From the ground you will not notice where one ends and the other begins. And the top of the spire will often be hidden behind the usual Petersburg clouds.

Igor Romanenko finally says:

- I sometimes get funny questions. Well, for example, what will happen if all the people in the tower gather on one side of it: Will it really tilt? I just laugh back. Nothing will happen to her. The design is super reliable. And unique to the country.

Igor Romanenko was telling - Lakhta Center construction control engineer.

Anton Ratnikov visited the site.

Video about the metalwork

-

Photo news can be viewed on our Telegram channel .

All Articles