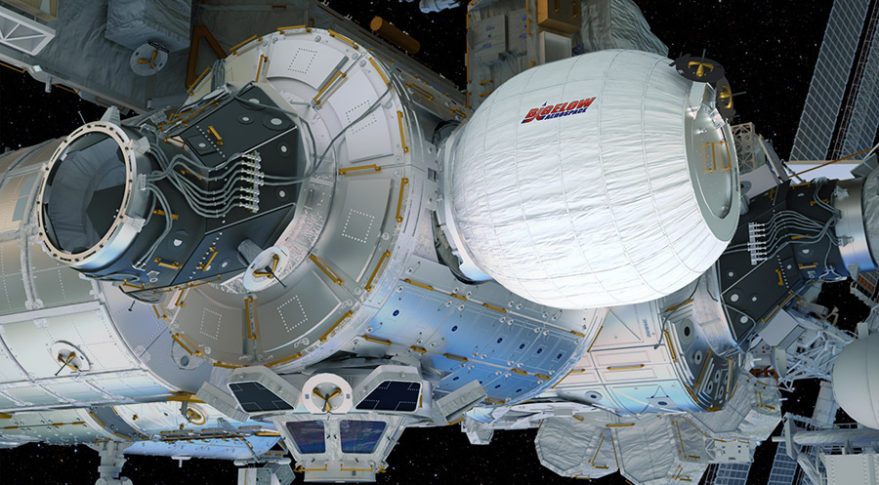

Inflatable Bigelow module on the ISS for a year, everything goes according to plan

A whole year has passed since NASA managed to dock the Bigelow inflatable module from the company Bigelow Aerospace with the ISS, after which the filling of the module with air and bringing its volume to the planned one ended with success. The agency hopes that in the future such modules will be able to be delivered without problems into orbit, making up fairly complex structures that can serve almost any need.

It was necessary only to check whether the walls of the module can withstand a collision with particles of space debris. In that case, of course, if such collisions occur. After all, we must not forget that the wall of Bigelow could not be as reliable as the wall of the usual, "solid" module of the ISS. This reliability, of course, is only imaginary, since a more or less significant object can pierce that soft wall, which is hard. But still, no one wants to be in an air-filled bubble in outer space when this bubble starts to deflate. As it turned out, all the fears are in vain: the Bigelow module is working perfectly - for the whole year there were no particularly significant incidents.

Its walls are not just a fabric, but a material with a complex structure consisting of Kevlar-like fibers, which resists mechanical stress well. Sensors located in the walls showed that there were probably collisions with some particles. According to scientists, micrometeorites and small fragments of space debris crashed into the module's material, but they could not cause any damage to the shell.

In principle, the developers talked about this a year ago, arguing that inflatable modules are no worse than ordinary ones confronting particles of space debris. Well, since the shell is made of special fiber, astronauts should feel much more comfortable in such a module for the simple reason that the fiber does not provide such strong sound effects as plating made of hard materials.

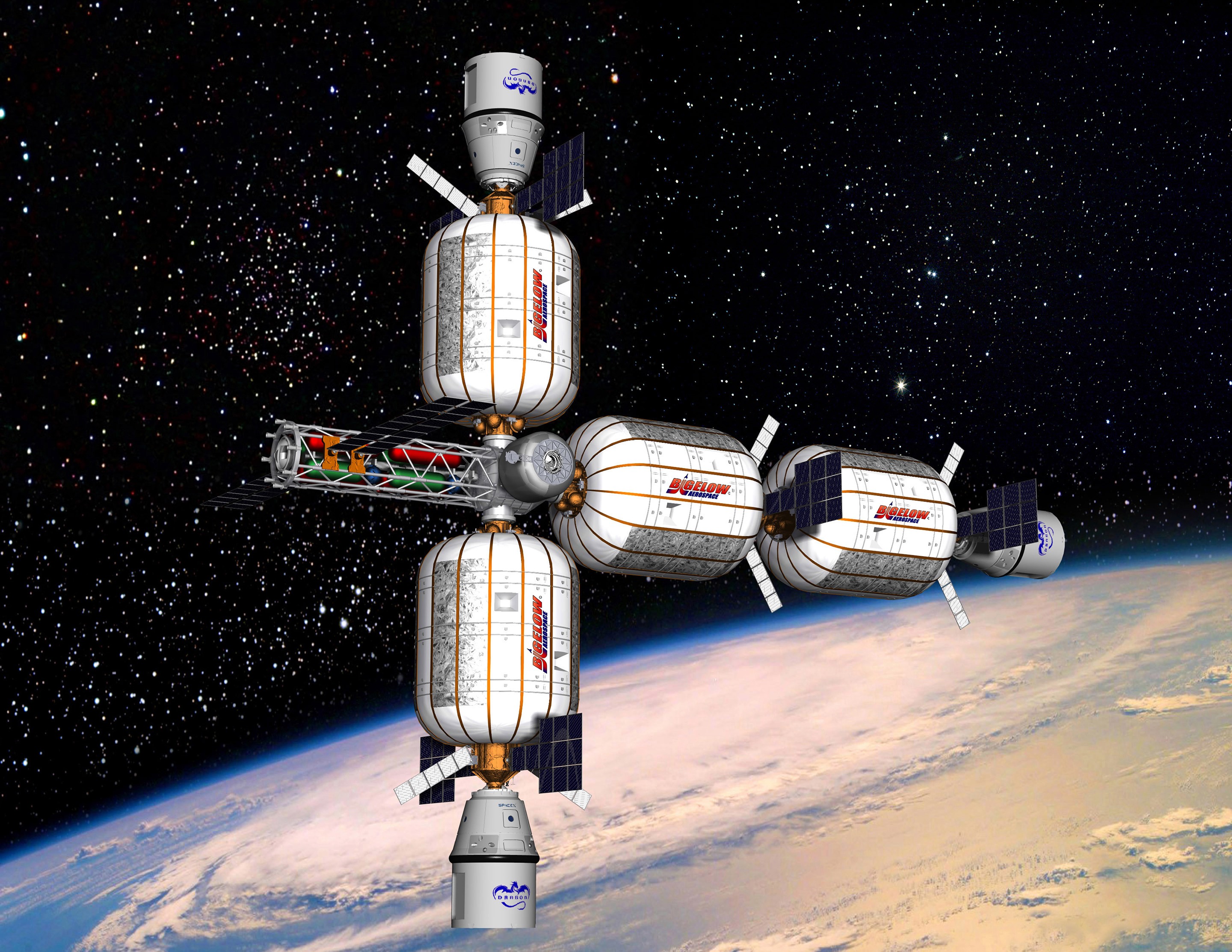

Perhaps this is what future space stations will look like.

It is worth noting that the entire first year of operation of the module in outer space was devoted to testing its strength. Now NASA will not forget about checks of this kind, but the focus has shifted slightly in a different direction. Now the agency will address the issue of cosmic radiation and its influence on people and equipment inside the module.

According to the developers of the module, its walls are as good in terms of protecting the inhabitants from radiation as the walls of conventional modules of the ISS, and it is possible that the development of Bigelow in this regard and exceeds the "competitors". By the way, here the fiber is also better than metal, since it partially disperses the radiation of the Sun, and the fiber of the plating of the inflatable module does not.

Inside the module were installed special sensors that measured the level of radiation during this year. According to NASA experts, the radiation level was not exceeded - the figures are about the same as in conventional ISS modules. The engineers at Bigelow Aerospace, they said, were happy to hear this news, but work on improving the structure of the modules continues.

Scientists are going to conduct further experiments. So, using a 3D printer developed by Madi In Space, astronauts are going to print a special radiation shield. They will close one of the two sensors inside the module. The thickness of the first screen is only 1.1 mm, but in the future it is planned to print shields and thicker ones - 3.3 mm and 10 mm. The task is simple - to understand whether the astronauts, using available tools, to protect themselves from radiation without help from the Earth.

The inflatable module from Bigelow Aerospace is about 9 times lighter than a standard module with an aluminum shell. The mass of the inflatable module is slightly more than a ton, 1360 kilograms. And the mass of the aluminum module Unity, which is now used on the ISS - more than 11 tons, 11793 kilograms. Plus, the Beam is easier to put into orbit, since it initially occupies a small volume, and then expands into orbit.

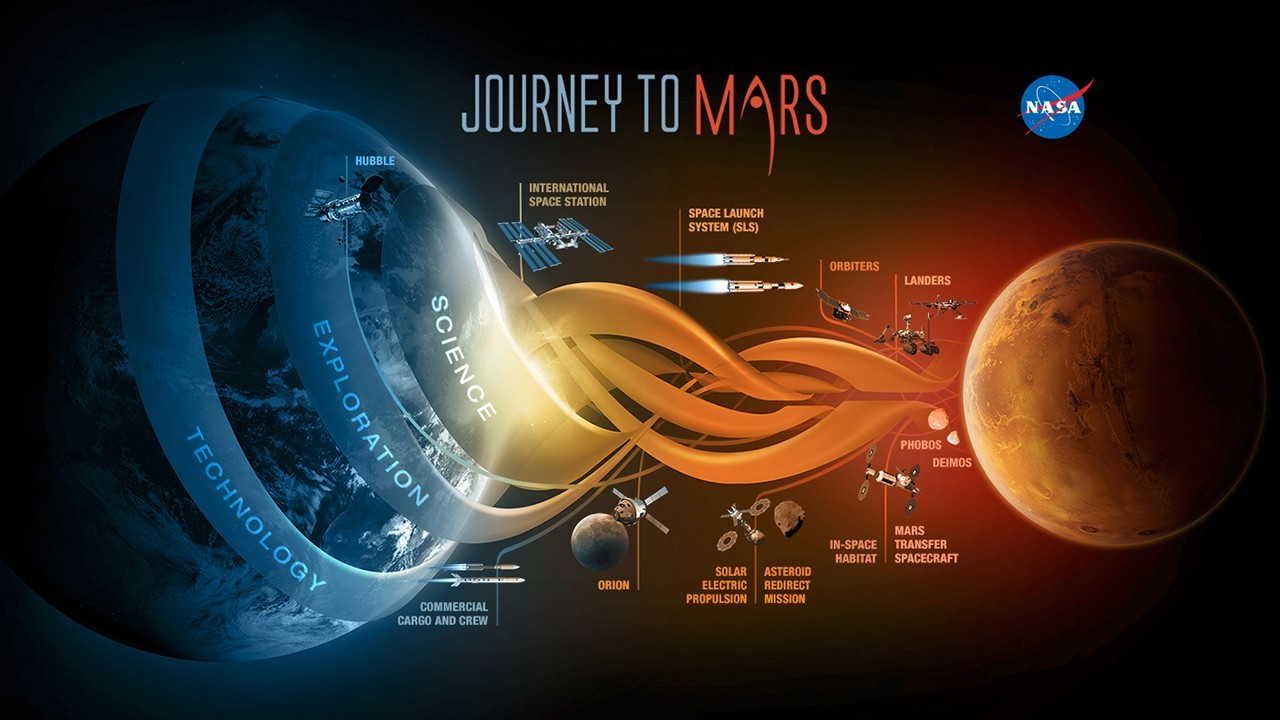

Las Vegas-based Bigelow Aerospace is one of six companies that collaborate with NASA on a commercial basis as part of a project to develop prototype residential modules in deep space. These developments, according to NASA's plan, will be used to create orbital stations on the Moon and Mars, not to mention the Earth. As part of this cooperation, NASA allocates six companies $ 65 million over two years, with the possibility of additional funding in the next, 2018. In addition, each of the partners should be able to cover at least 30% of the cost of the work at their own expense. The partnership itself is called Next Space Technologies for Exploration Partnerships-2 (NextSTEP-2).

All Articles