Overview of high-temperature 3D printers with Formnext 2017

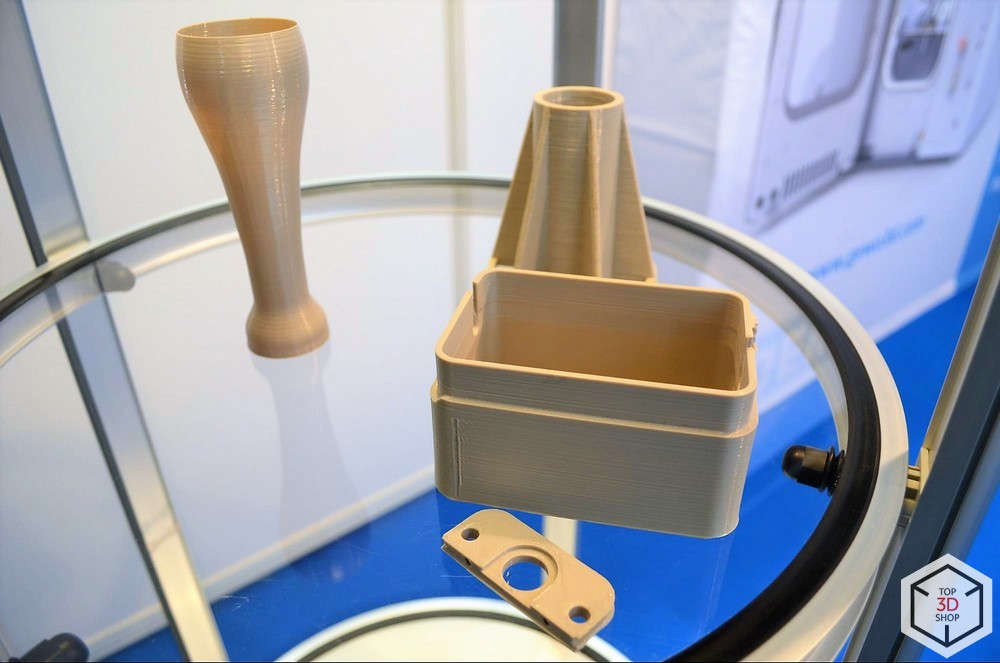

We continue to publish materials on the results of the Formnext 2017 exhibition held in Frankfurt am Main. For a general overview of the new products, read here . Today we note a significant increase in the number of 3D printers for working with high-temperature engineering plastics since last year, starting with polycarbonate and then to polyamides, Ultem, PEEK, PPSU and composites based on them.

These materials are used in the aerospace industry, chemical industry, medicine - where such properties as low weight, resistance to high temperatures, mechanical strength, chemical inertness, biocompatibility are in demand. We wrote more about engineering filaments and their application here.

Differences industrial 3D printers

To work with engineering plastics, the printer must have a high-temperature extruder. Here there are two classes of equipment. Junior - up to 300 ° C, this is enough for modifications of ABS, polycarbonate and polyamides. The oldest is above 300 ° C. For PEEK or Ultem you need about 400.

Extruder is not all. A heated platform or vacuum table is imperative to hold the part in place. And the printing should take place in a working chamber isolated from the outside world, with the support of the set temperature. Failure to comply with the regime leads to deformation or violation of the integrity of the printed object.

So, consider the samples seen.

Intamsys

The Chinese manufacturer offers four models of 3D printers. Basic Funmat and Funmat Pro work with familiar plastics, from PLA to nylon, and composites. Funmat HT and Funmat Pro HT are already able to print from PEEK, Ultem and PPSU.

Intamsys FUNMAT , FUNMAT HT

- Working chamber: 260 x 260 x 260 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.4 mm;

- FUNMAT: extruder temperature up to 280 ° C, table up to 150 ° C;

- FUNMAT HT: extruder temperature up to 450 ° C, table temperature up to 160 ° C.

Compact printers with a closed working chamber, for the HT version it is equipped with heating, the maximum temperature is 90 ° C.

Intamsys FUNMAT PRO , FUNMAT PRO HT

- Working chamber: 450 x 450 x 600 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.4 mm;

- FUNMAT PRO: extruder temperature up to 280 ° C, table up to 150 ° C, chambers up to 60 ° C;

- FUNMAT PRO HT: extruder temperature up to 450 ° C, table up to 160 ° C, chambers up to 120 ° C.

Industrial printers for printing large parts with high-temperature plastics, equipped with a heated working chamber.

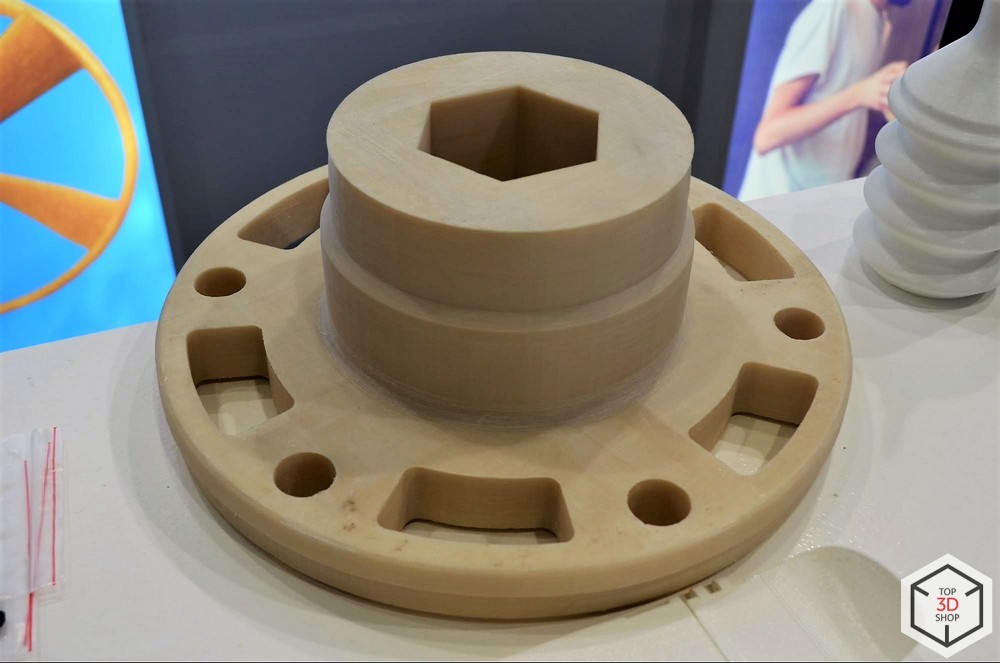

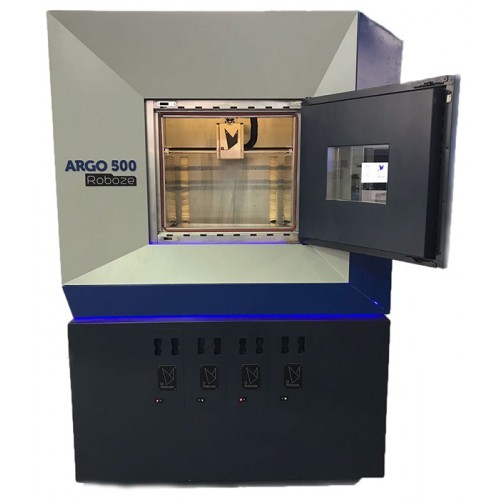

ROBOZE

One of the leading companies for the production of high-temperature 3D-printers, we wrote about it in more detail here . Offers three printers for working with engineering filaments. Roboze One - the base model, for ordinary plastics - from PLA, to polyamide inclusive. Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - large installation, with a working chamber of 500 x 500 x 500 mm. Printers Roboze interesting rejection of the drive belts and use to move the print head transfer gear-gear.

Roboze One +400

- Working chamber: 200 x 200 x 200 mm;

- extruder temperature: up to 400 ° C;

- layer thickness: from 50 microns.

The printer is designed with an emphasis on reliability, all parts of the extruder are made of metal.

Roboze Argo 500

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 550 ° C;

- chamber temperature: up to 180 ° C.

In the older model, the Roboze has a vacuum table to hold the part. Filament compartments are heated. When one coil ends, the unit automatically switches to the next.

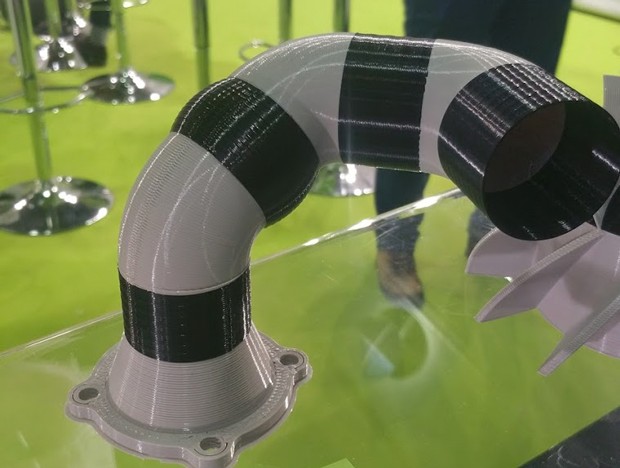

VSHAPER

Polish manufacturer, whose product range includes high-temperature medical printers and five-axis 3D printing presses.

VSHAPER 270 Med

- Working chamber: 270 x 270 x 200 mm;

- extruder temperature: up to 450 ° C;

- layer thickness: from 50 microns.

A medical-oriented printer with an anti-bacterial coating of the working chamber and an integrated UV sterilizer sterilizing each layer during printing. The main purpose is to print implants and accessories for surgical operations.

VSHAPER 5-Axis Machine

- Work area: cylinder with a diameter of 300 mm and a height of 300 mm;

- automatic hotband change;

- heated chamber;

- possibility of printing one model with several materials.

Five-axis design allows you to print complex shapes without support. The ability to print one model with several materials with different properties allows you to create complex parts, for example, with an internal core of a more durable material, or with a coating or inserts of flexible. For convenience of printing, the platform is also optimized with different materials - it is divided into cells, which can be used to set different heating temperatures.

The printer is already available for pre-order, and shipments will begin, according to the manufacturer, from January 2019.

3DGENCE INDUSTRY F340

- Working chamber: 260 x 340 x 340 mm;

- layer thickness: from 150 microns;

- chamber temperature: up to 85 ˚C;

- extruder temperature: up to 500 C.

The printer can be equipped with one of three printing modules. Standard - up to 265 C, medium - up to 350 C, high-temperature - up to 500 ˚C. Printed modules - with two hotandami, for the main and auxiliary materials. Among other interesting features, we note the pre-heating of plastic and the coil mass sensor.

Apium

Apium Additive Technologies GmbH is a German company that manufactures small printers for working with high-temperature filaments such as PEEK, Ultem and PPSU, as well as composites. Apium is translated from Latin as “celery”. For products claimed to support printing metal-filled filaments for further baking.

Apium P155

- Working chamber: 155 x 155 x 155 mm;

- extruder temperature: up to 520 ° C;

- table temperature: up to 160 ° C;

- layer thickness: from 100 microns.

Desktop high temperature printer with a small printing area. It is the heir to Indmatec HPP 155. Apium offers a slightly larger model - the P220 , with a printed area of 200 x 160 x 160 mm.

GEWO 3D

The German manufacturer offers one high-temperature printer, with a very serious margin on the heating temperature of the printing platform and the working chamber.

GEWO HTP 260

- Working chamber: 350 x 150 x 165 mm;

- layer thickness: from 20 microns;

- extruder temperature: up to 450 ° C;

- table temperature: up to 270 ° C;

- chamber temperature: up to 260 ° C.

Prints with all common engineering plastics, equipped with two extruders. The possibility of installing a spindle for machining parts.

MiniFactory Innovator 2

- Working chamber: 300 x 160 x 160 mm;

- layer thickness: from 30 microns.

Finnish two-extruder printer, manufacturer focuses on PEEK printing. Other engineering plastics such as ABS, polycarbonate or Ultem are also supported.

Omni3D Factory 2.0

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 360 ° C;

- table temperature: up to 130 ° C;

- chamber temperature: up to 70 ° C.

An industrial printer from Poland is equipped with two extruders and can print large-sized parts made from ABS, polycarbonate, polyamide and composites based on them.

DynamicalTools DT600

- Working chamber: 600 x 450 x 450 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 500 ° C;

- table temperature: up to 150 ° C.

The Spanish printer with two independent print heads, besides the usual printing, supports the modes of printing two identical or mirror details simultaneously. Works with all high-temperature filaments up to PEEK, Ultem, PPSU. Equipped with plastic heating systems and automatic change coils.

HAGE3D 140L

- Working chamber: 700 x 500 x 400 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 450 ° C;

- chamber temperature: up to 85 ° C.

Austrian industrial apparatus supporting work with most engineering filaments and composites. Heated working chamber, three-zone heating table.

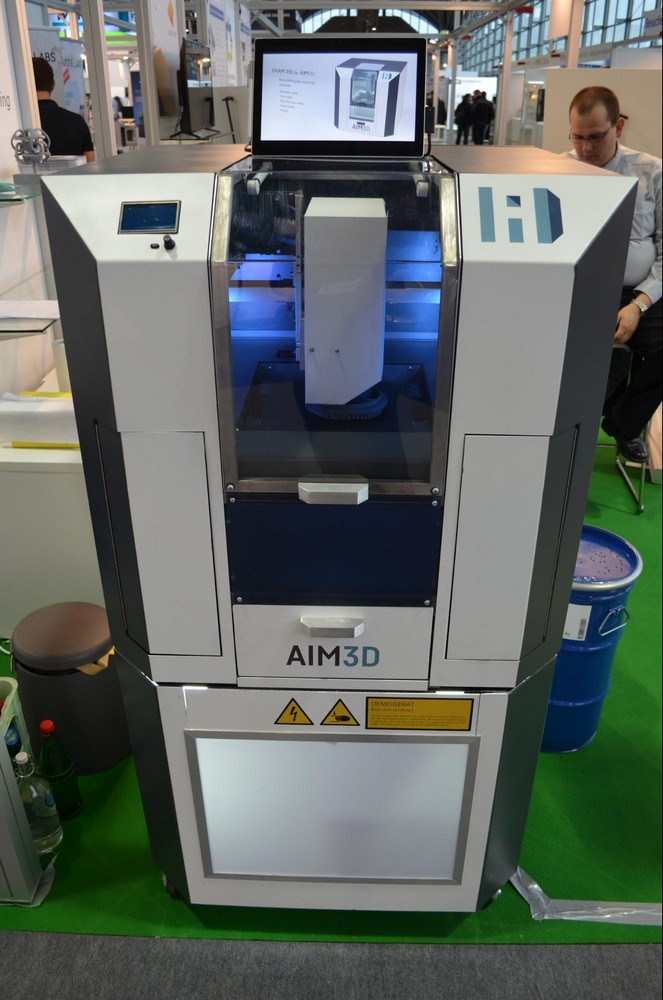

AIM3D

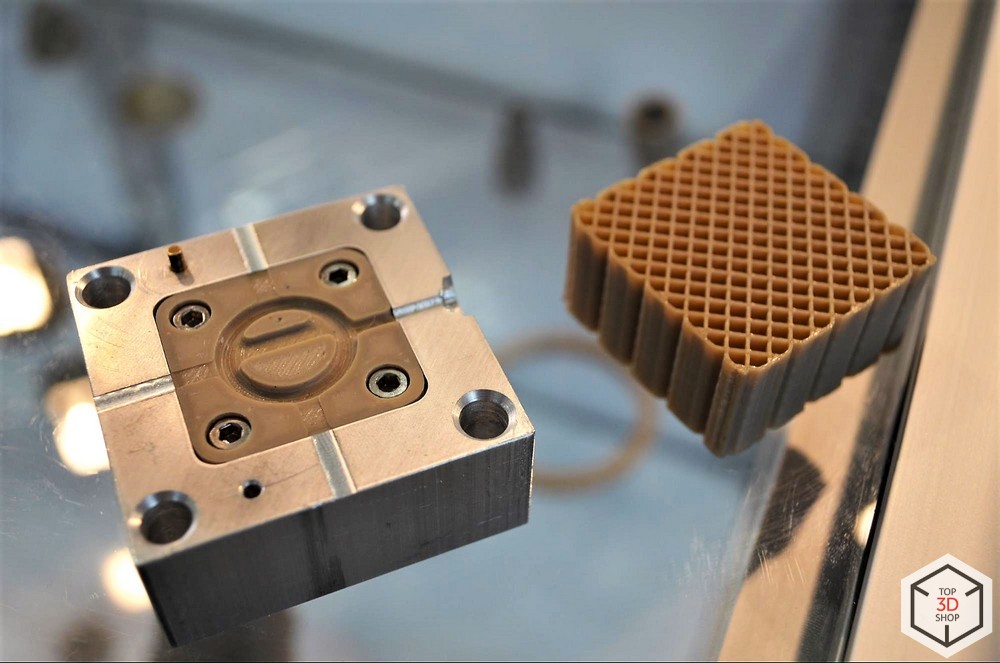

The company offers a complex of equipment for the manufacture of metal objects. At the first stage, the part is printed on a 3D printer, on the second - it is placed in a furnace where the bonding plastic burns out and the metal filler is sintered.

AIM3D ExAM 255

- Working chamber: 255 x 255 x 255 mm;

- layer thickness from: 20 microns;

- table temperature: up to 120 ° C.

The printer does not work with the filament, but with the granules. This allows the use of raw materials for FDM printing, which are commonly used in MIM, Metal Injection Molding installations. You can also print with plastic granules; this is usually cheaper than using a filament.

AIM3D ExSO 90

- diameter of workpieces, up to: 90 mm;

- 6 sided heating;

- isolation and collection of vapors formed during sintering;

- temperature: up to 1350 ° C.

A furnace for high-temperature sintering of parts printed on AIM3D ExAM 255 in an inert gas atmosphere.

How to purchase an industrial 3D printer

Are you choosing an industrial 3D printer? Top 3D Shop is the official representative of most of the manufacturers mentioned in the review, we are ready for equipment delivery, commissioning, training and maintenance.

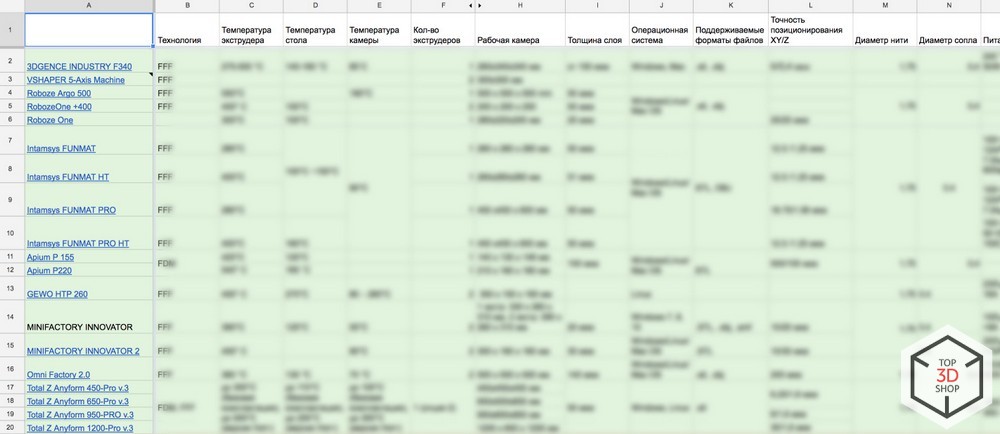

We made a comparative table for these machines, with technical nuances - temperature of printing and camera, materials used, number of extruders and estimated cost.

Prices for 3D printers that print with high-temperature plastics, like industrial equipment, often depend on a very flexible pricing policy of the manufacturer.

The price may vary from delivery to delivery, depending on many factors, and some manufacturers are categorically opposed to the publication of final prices in the public domain, because we do not specify prices in the article, and provide a table on request.

For detailed information and assistance in choosing an industrial high-temperature 3D printer, please contact Top 3D Shop specialists.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

All Articles