Overview of 3D printer Zenit 3D from the company 3Dtool

Welcome, dear readers Geektimes! With you, 3DTool, and today we will discuss a fairly well-known FDM 3D printer fully developed and made in Russia under the name ZENIT.

In addition to the text review, please watch the video review with lots of additional information about the printer (recommended).

Driven by the desire to give a competitive response to similar Russian and Western developments, having spent many months on implementation and testing. At the end of 2015, Zenit3D presented its own 3D printer with the same name Zenit.

In total there are 2 versions of this printer: This is Zenit, which we describe in this review, and Zenit DUO, which is characterized by the presence of two extruders. But first things first.

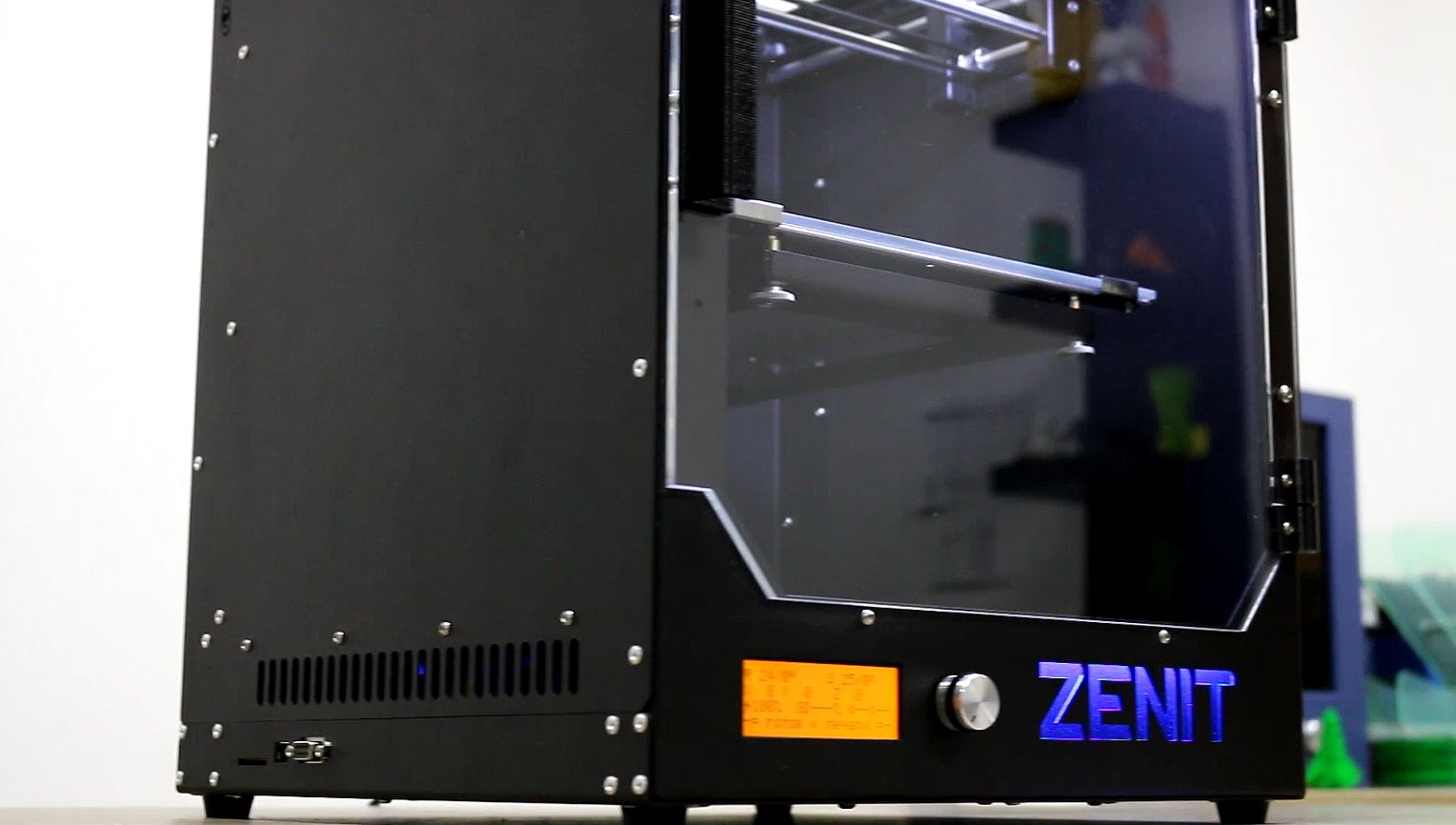

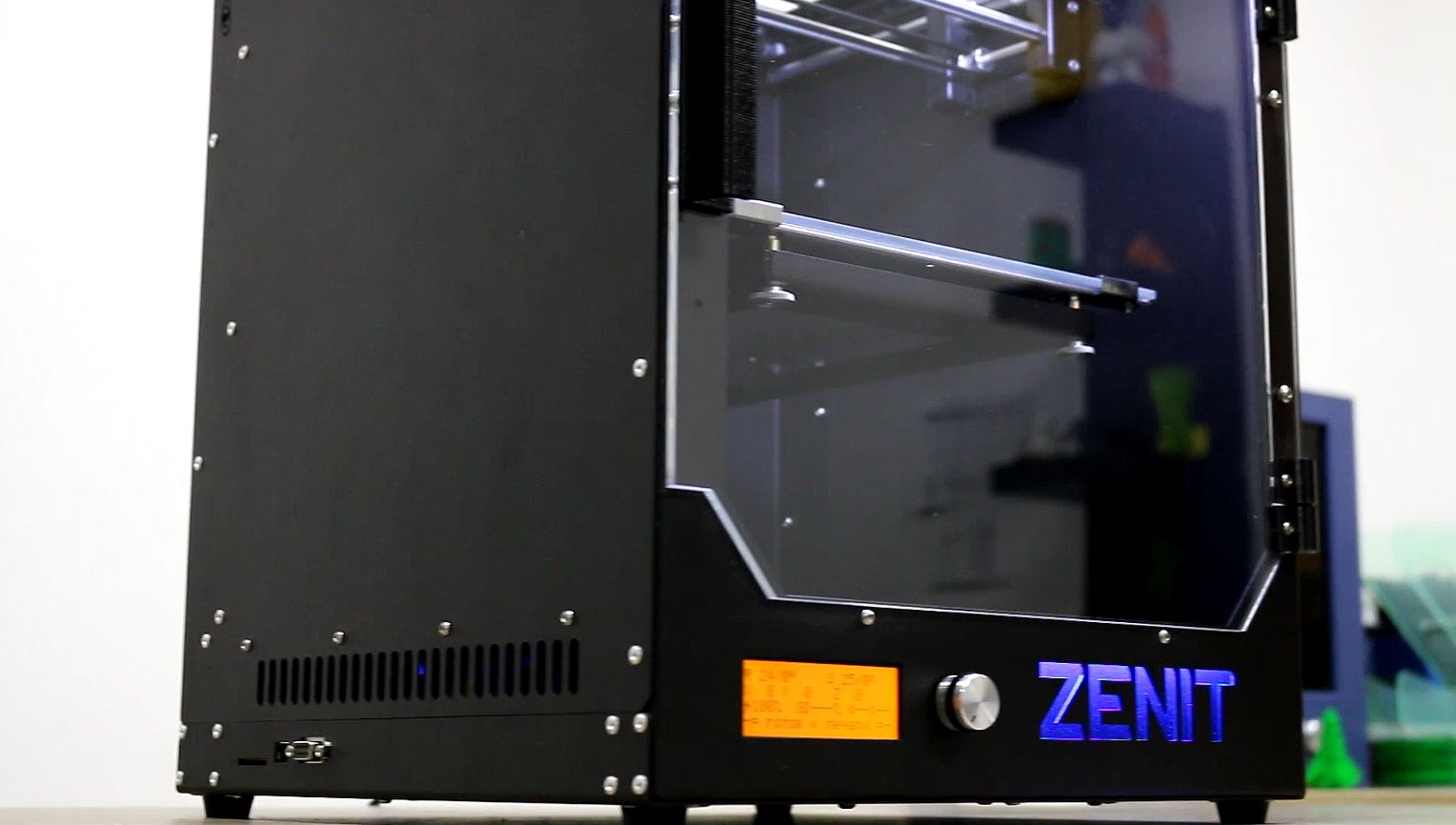

The first thing we see is a metal case that provides vibration resistance. The weight of the printer is about 20 kg.

On the front side of the printer, there is a transparent door of acrylic for easy monitoring of 3D printing and access to the working chamber.

The top of the 3D printer is not closed. Since the plastic for the printer is charged in the upper part of the extruder, it is convenient.

The plastic coil stand is a separate design. It comes with the printer included.

Also, the printer has a LCD display on the front panel, which makes its use convenient and ergonomic. Fully Russian-language interface. Management through the rotating joystick. Due to this, during printing we can control the printer and track parameters without being connected to a computer.

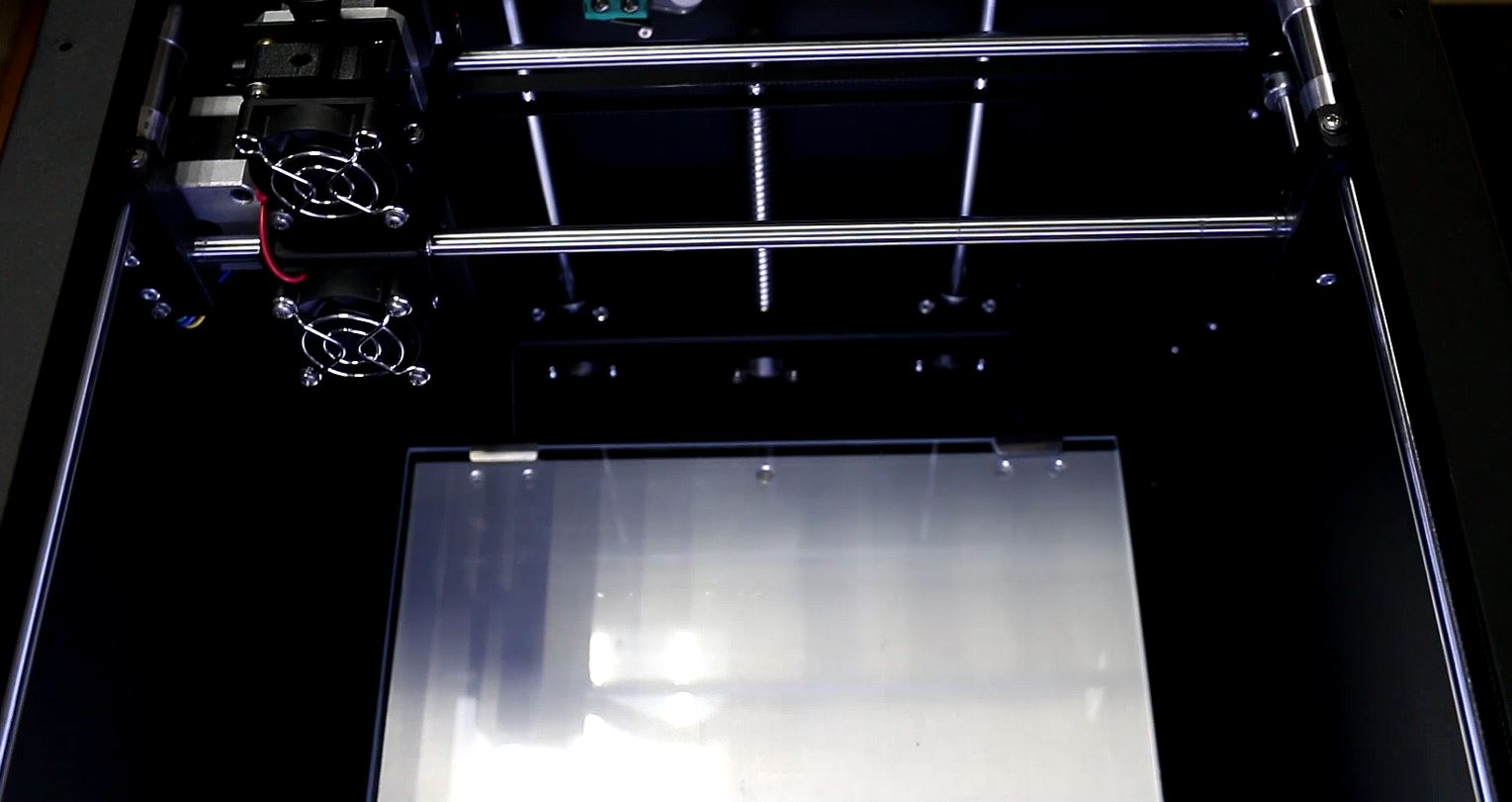

Now look inside.

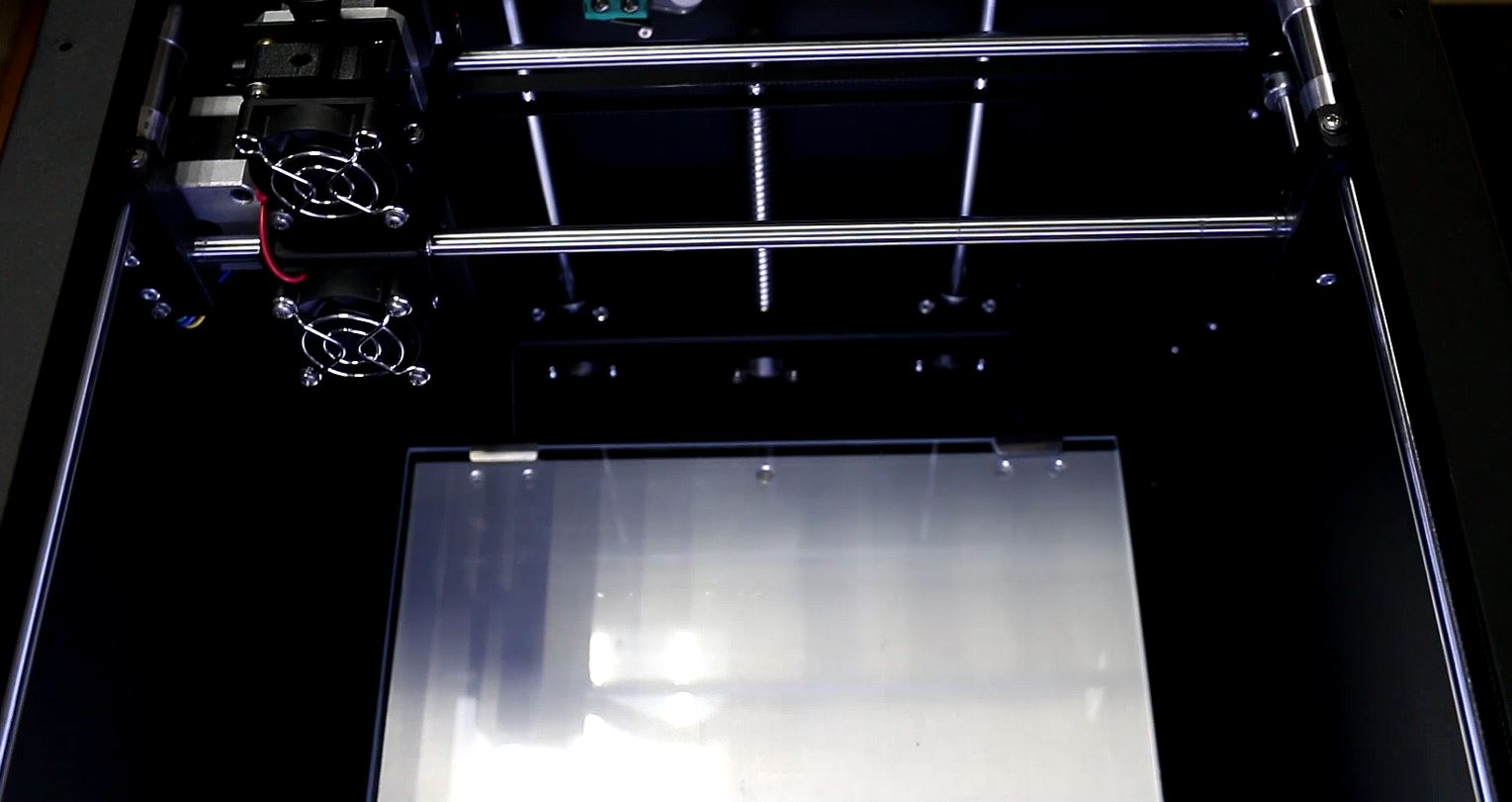

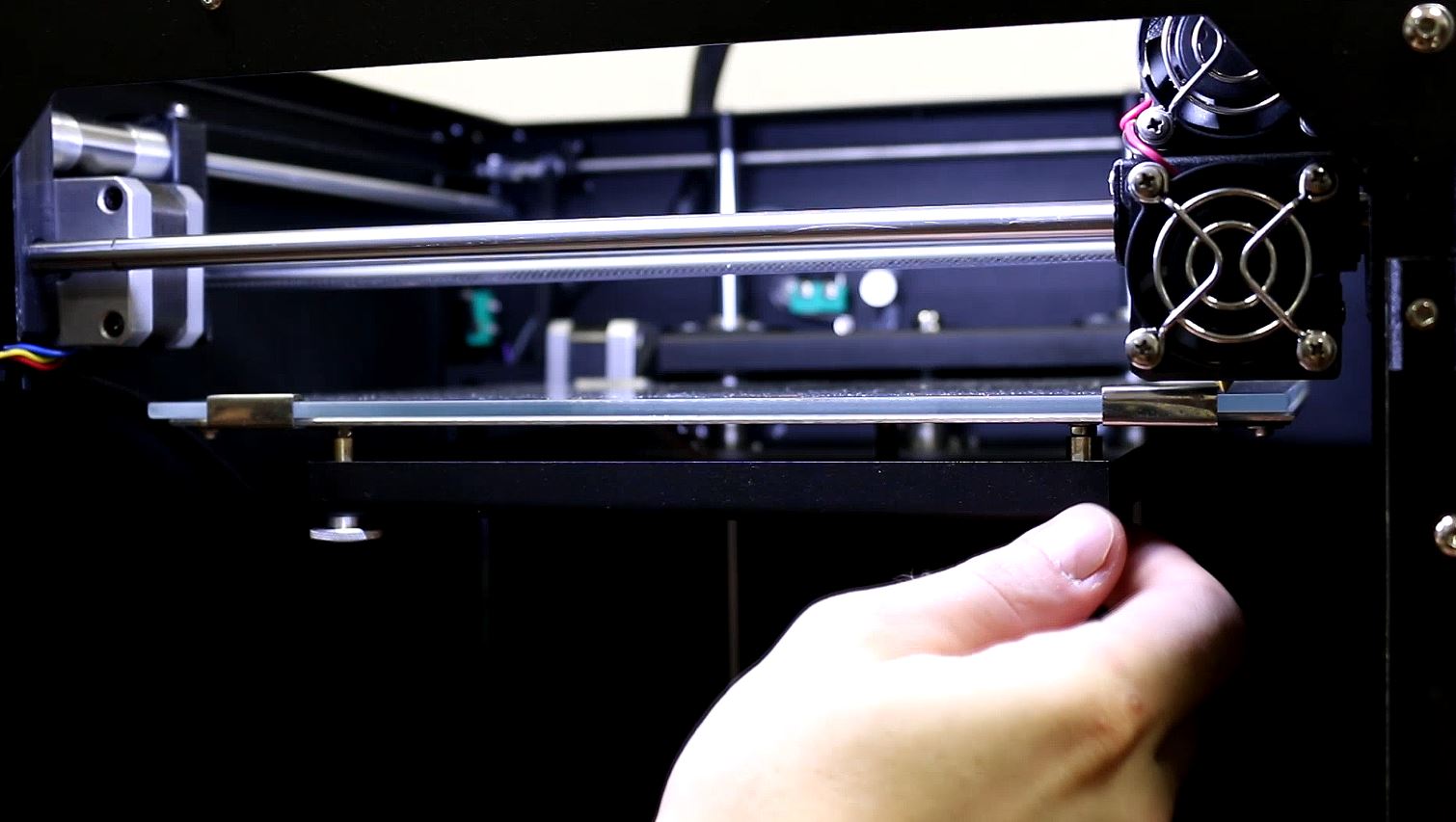

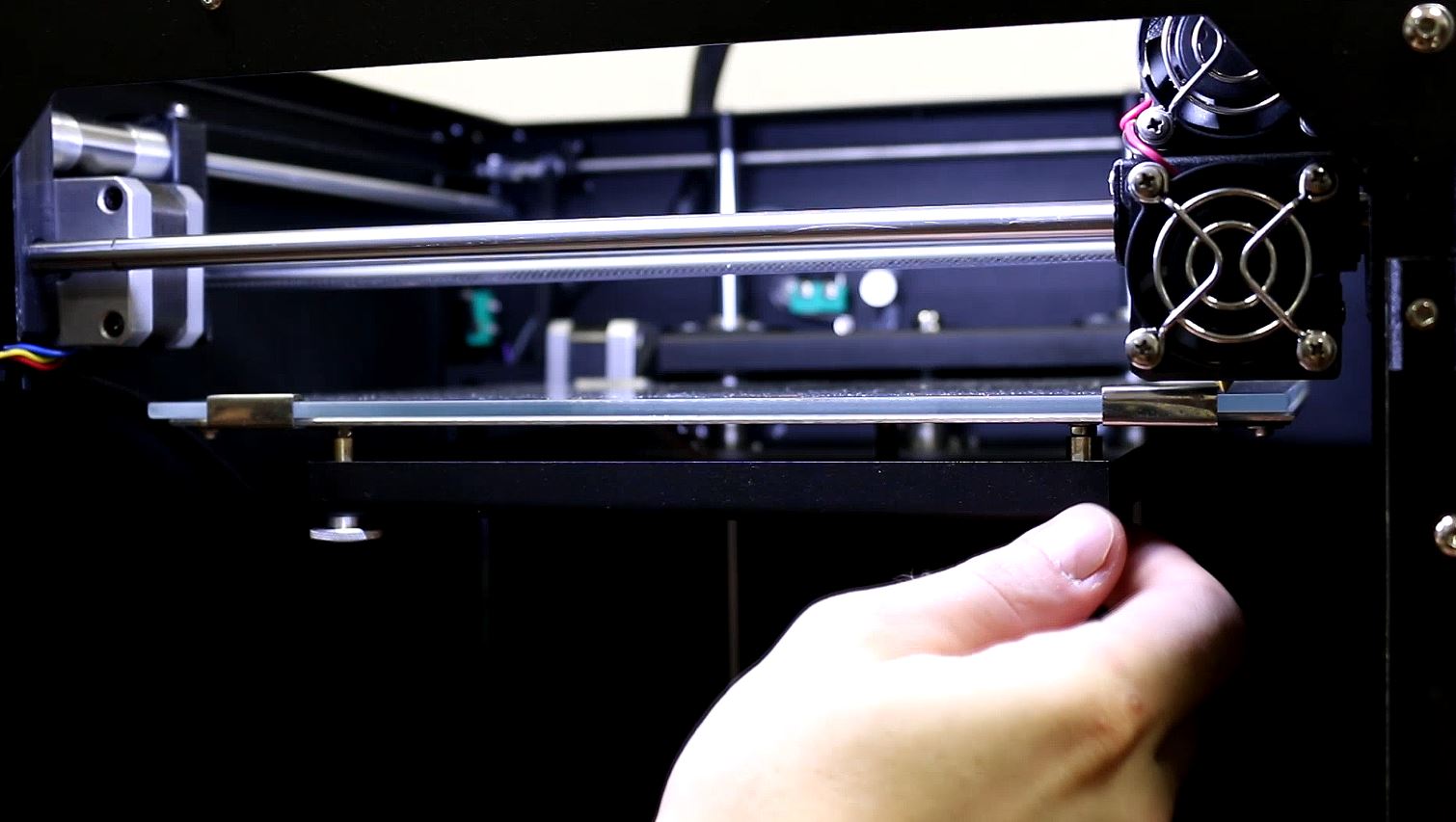

Open the door and immediately see the heated desk, made of aluminum, and for greater convenience there is also a removable glass.

There is also an indication of the heating of the table when it is cold, the inscription ZENIT glows blue,

and when the temperature rose to working — red.

The table itself heats up in less than 2 minutes, and its maximum temperature is 110 ° C.

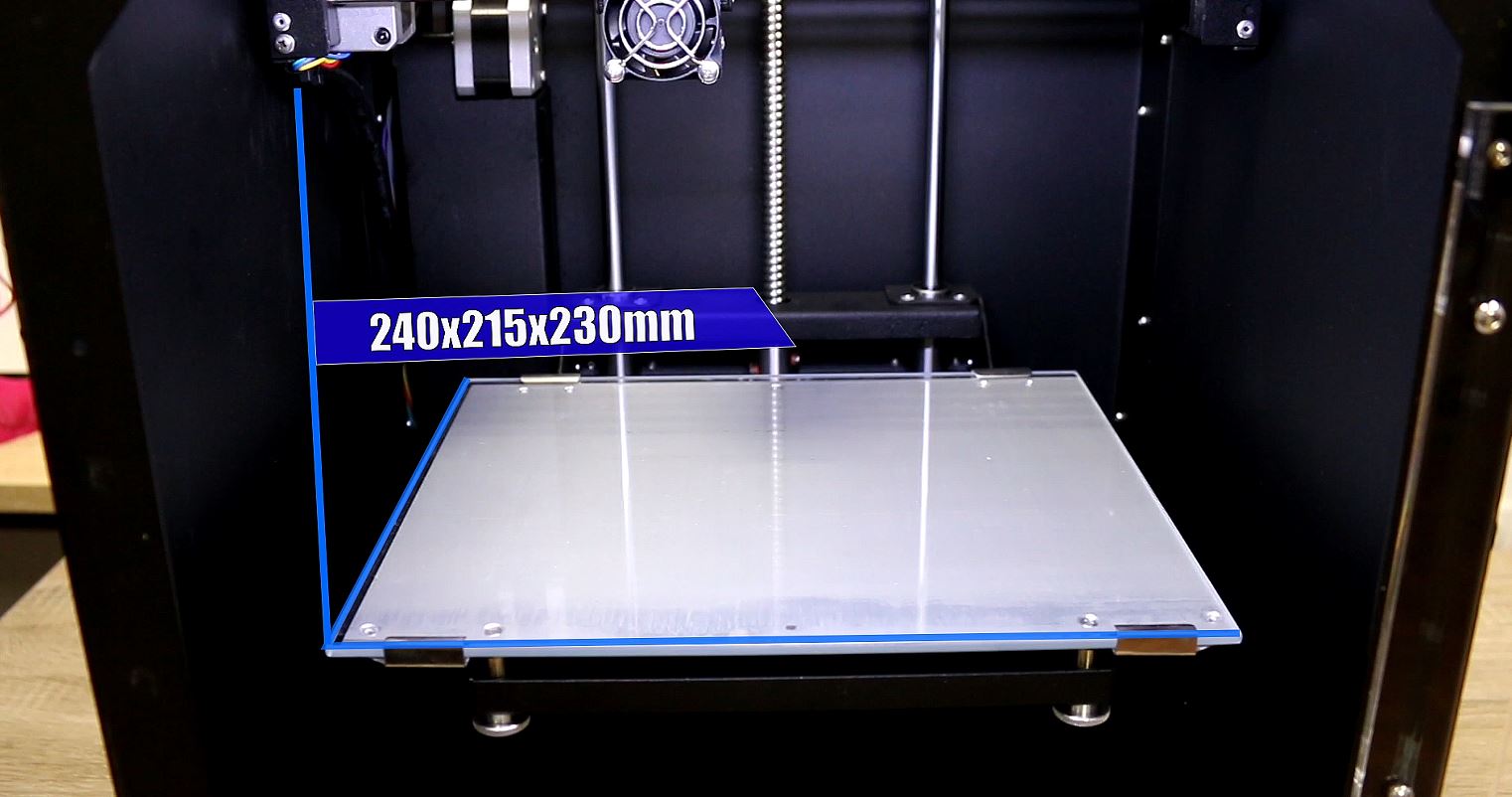

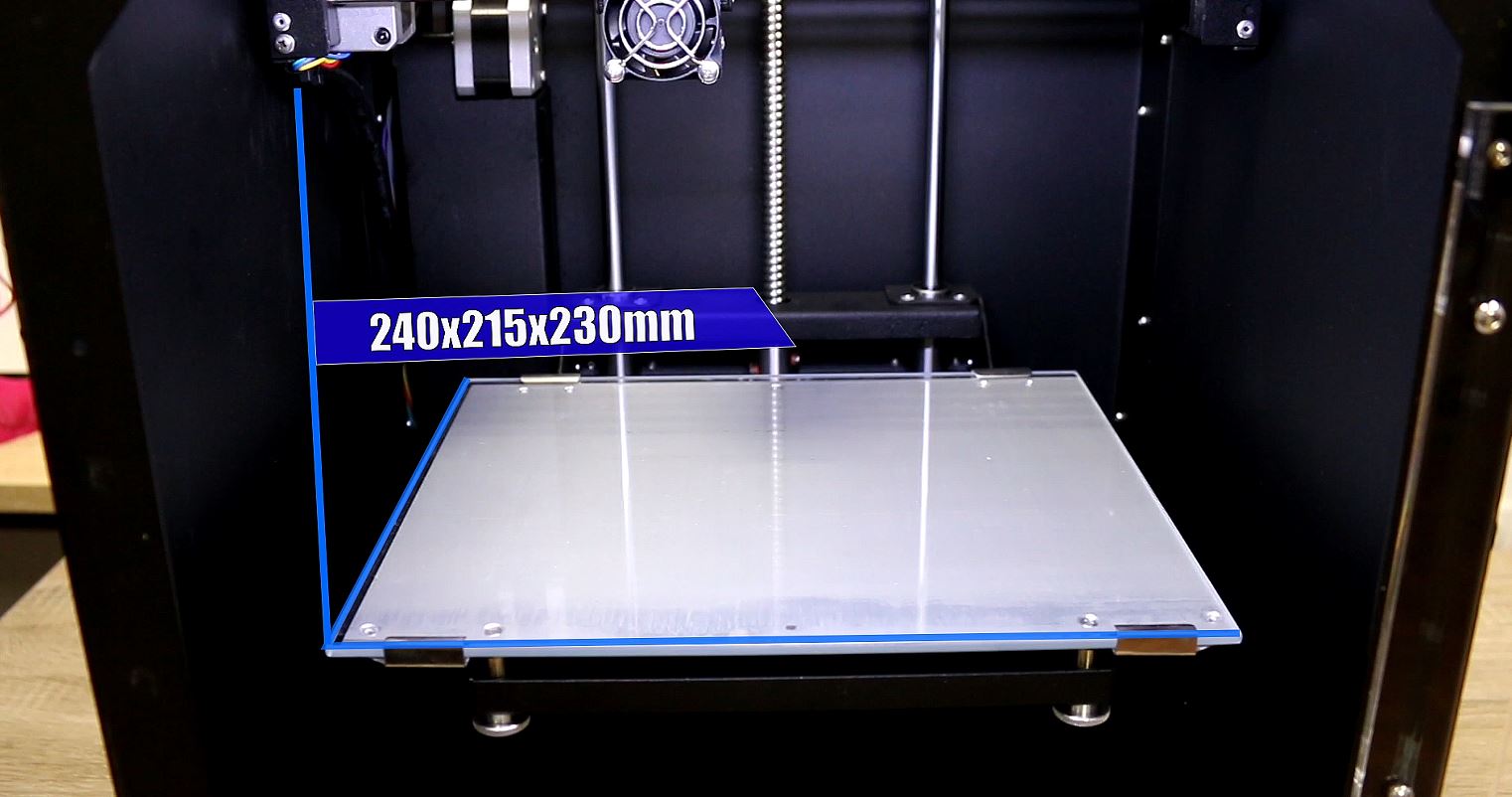

The maximum part size that can be printed in this printer is 240x215x230 mm, and the minimum layer height along the Z axis is 50 microns, which shows us about the large ambitions of this printer.

Zenit 3D printer calibration is performed in manual mode with the help of screws under the desktop, which just adjust the distance between the nozzle and the table. All you have to do is to hold your hand through an extruder at 5 points on the desktop.

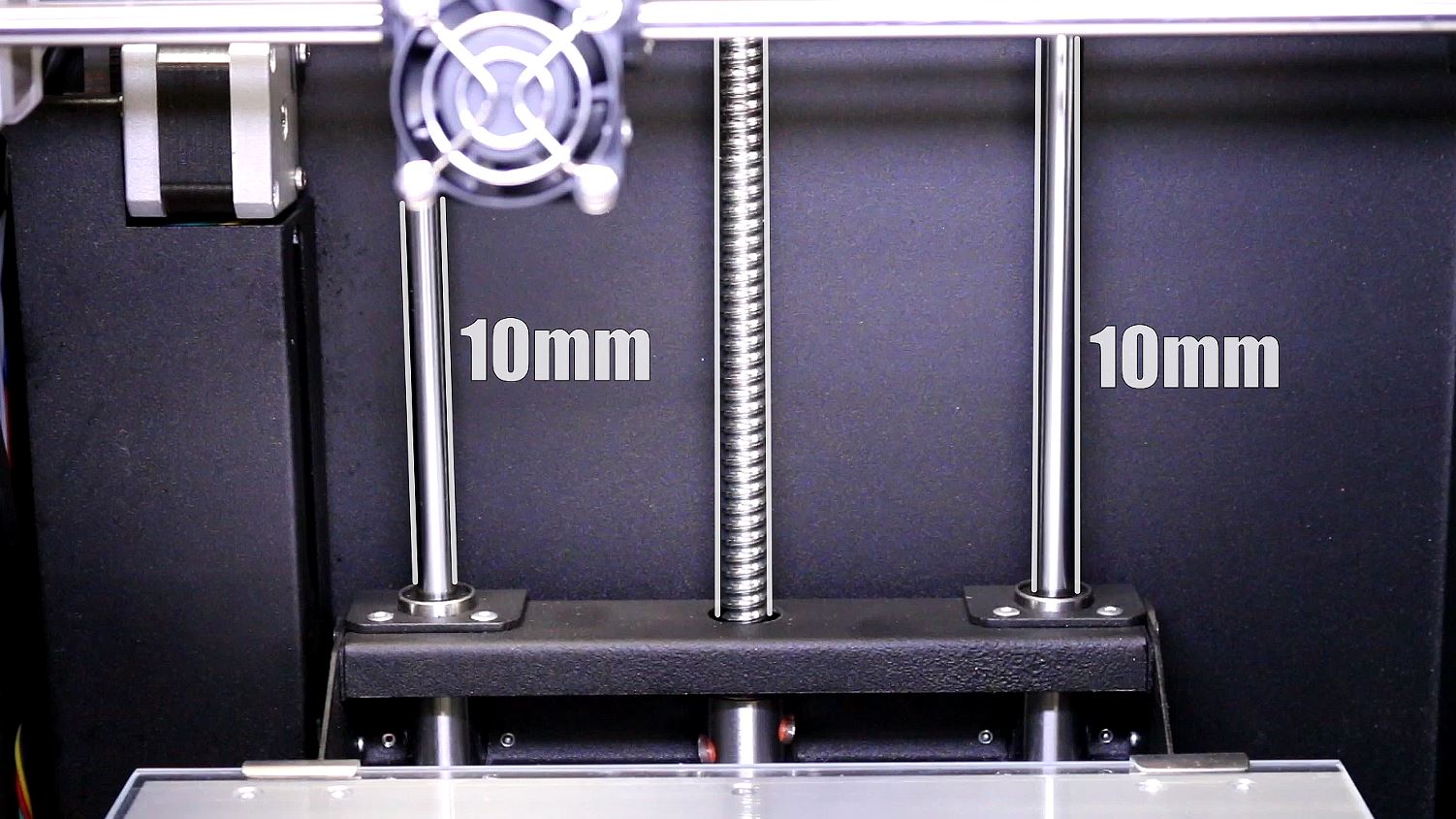

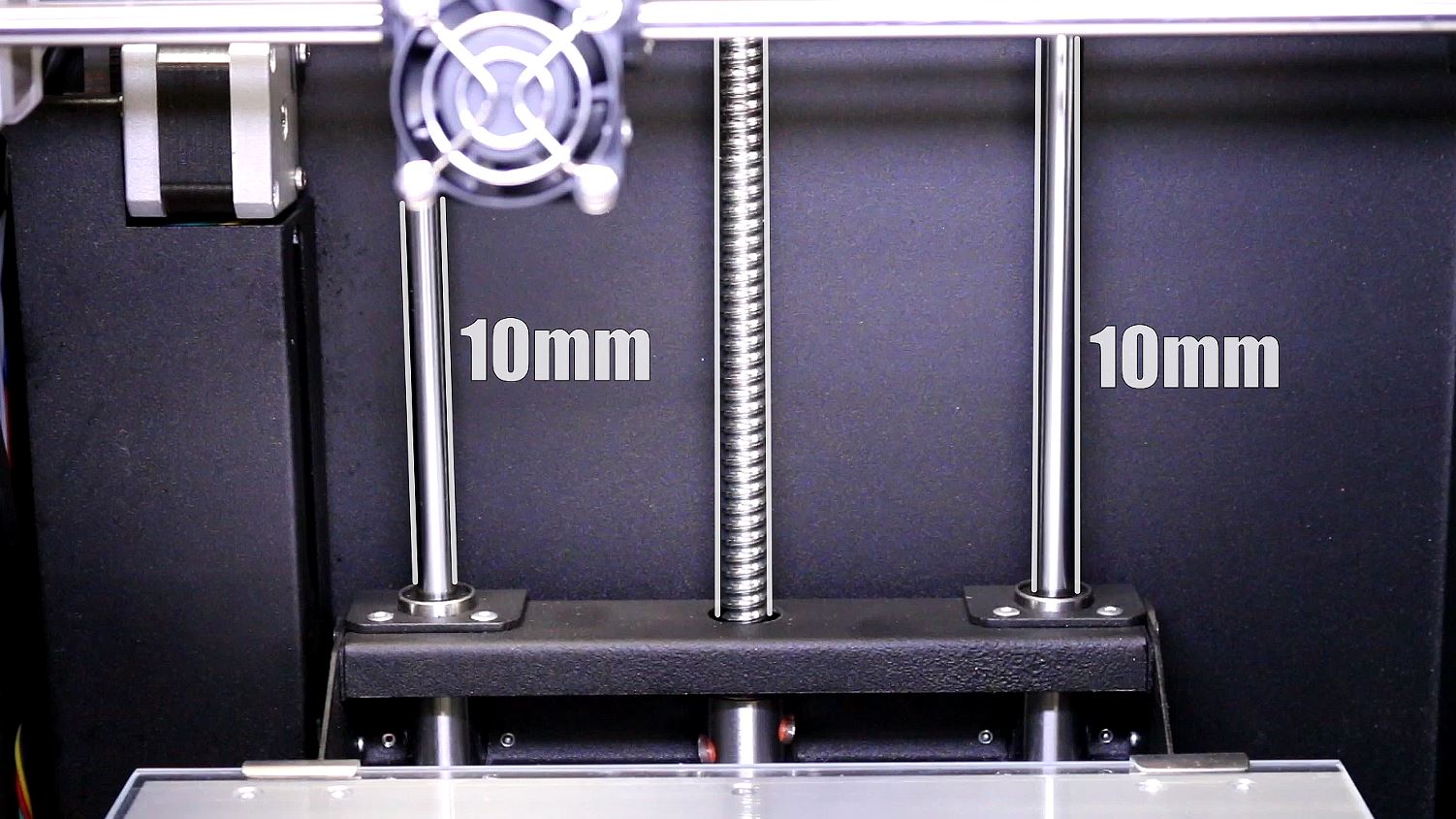

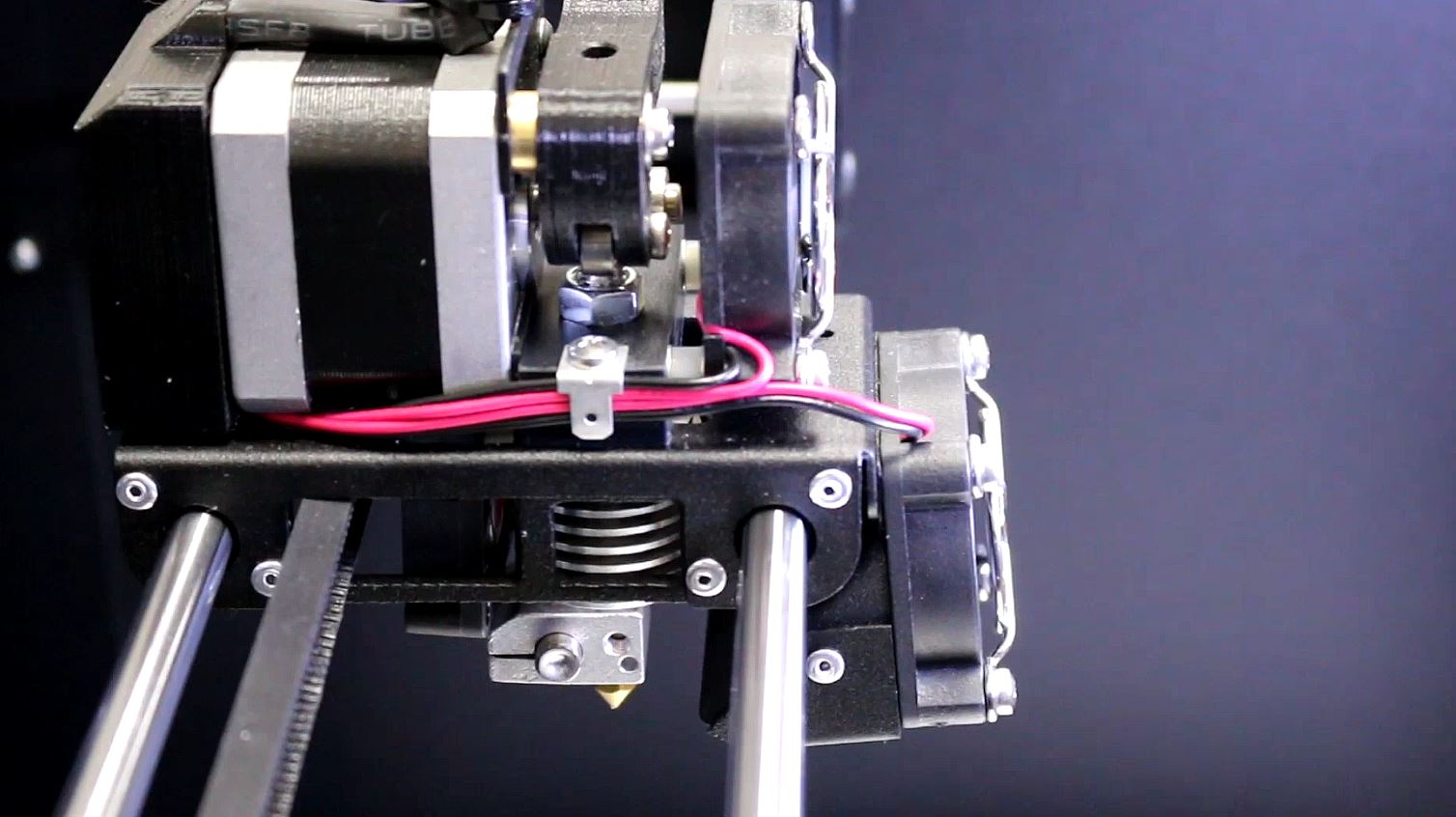

The Z axis uses a ball screw (installed on all printers from the end of 2016) and double 10 mm shafts.

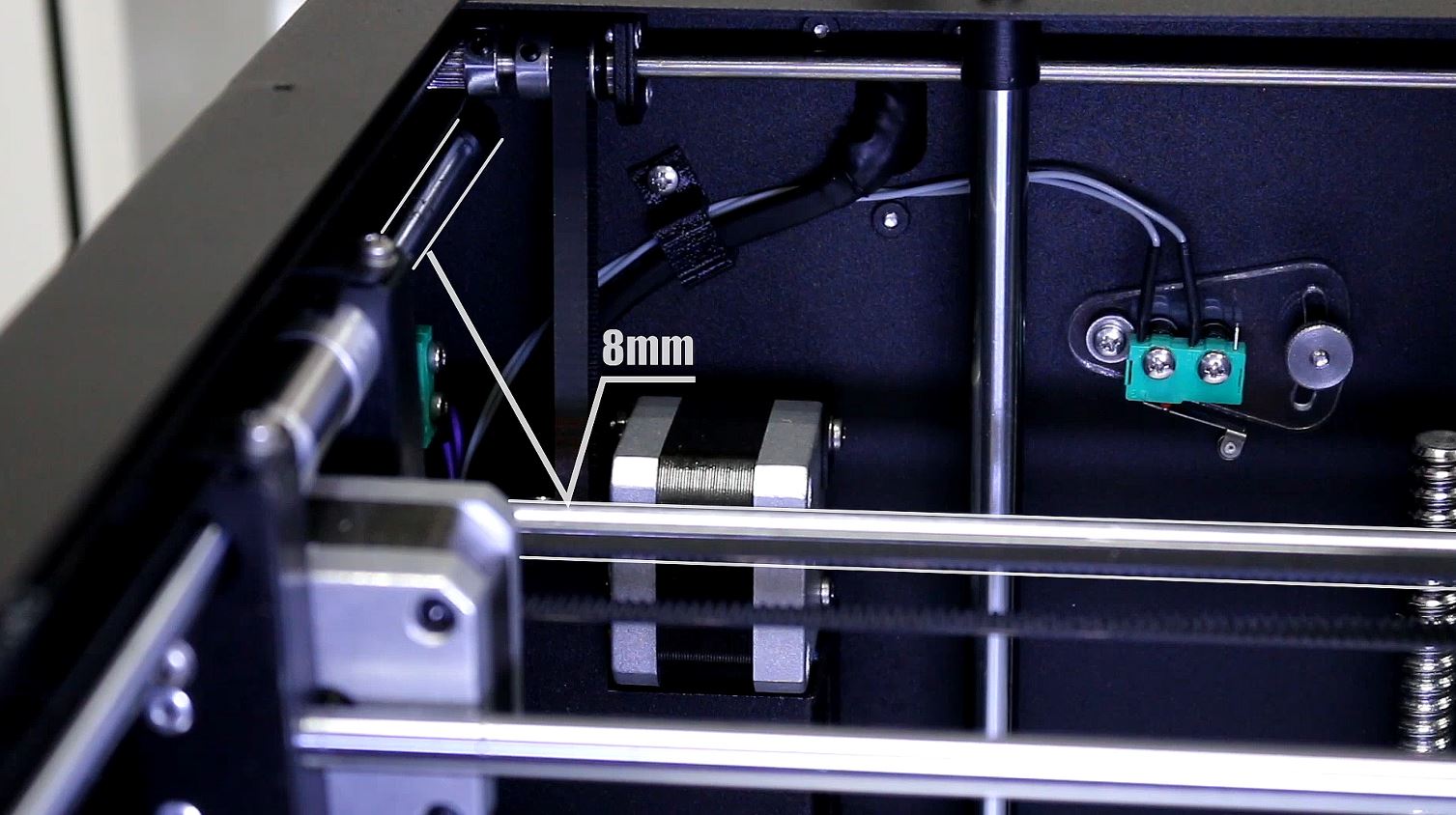

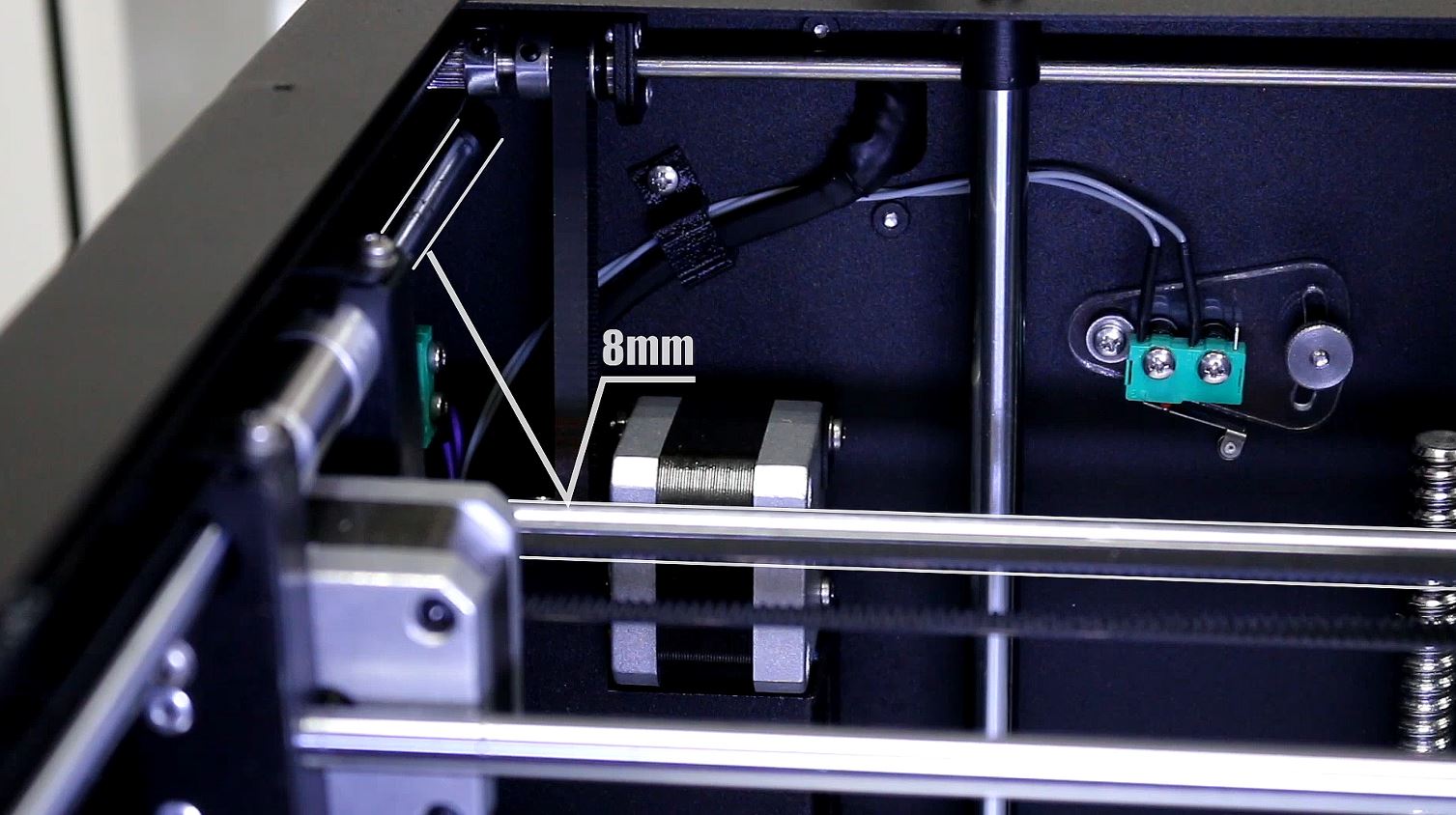

Axes X and Y have shafts with a diameter of 8 mm. The mechanics of the printer is driven by stepping motors through a toothed belt.

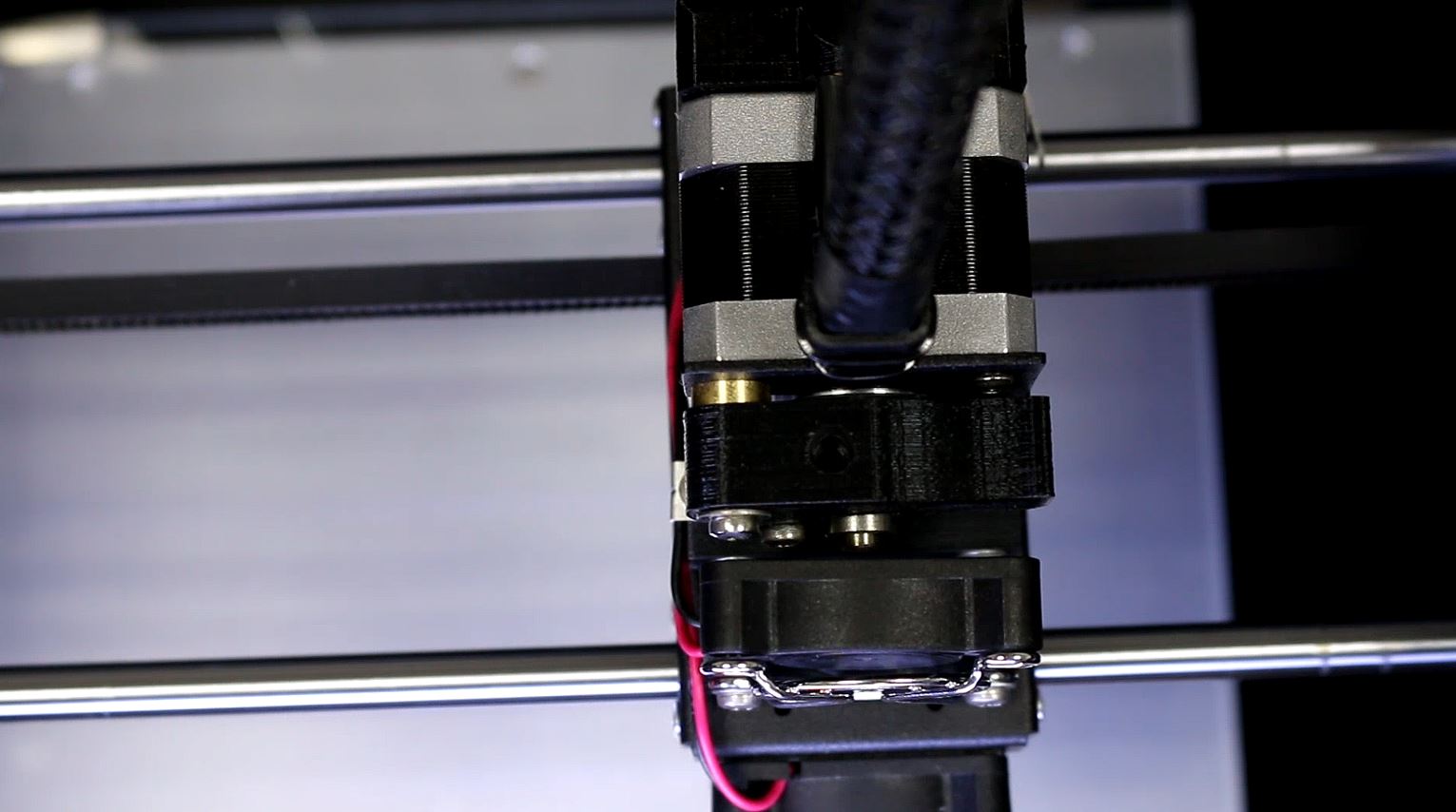

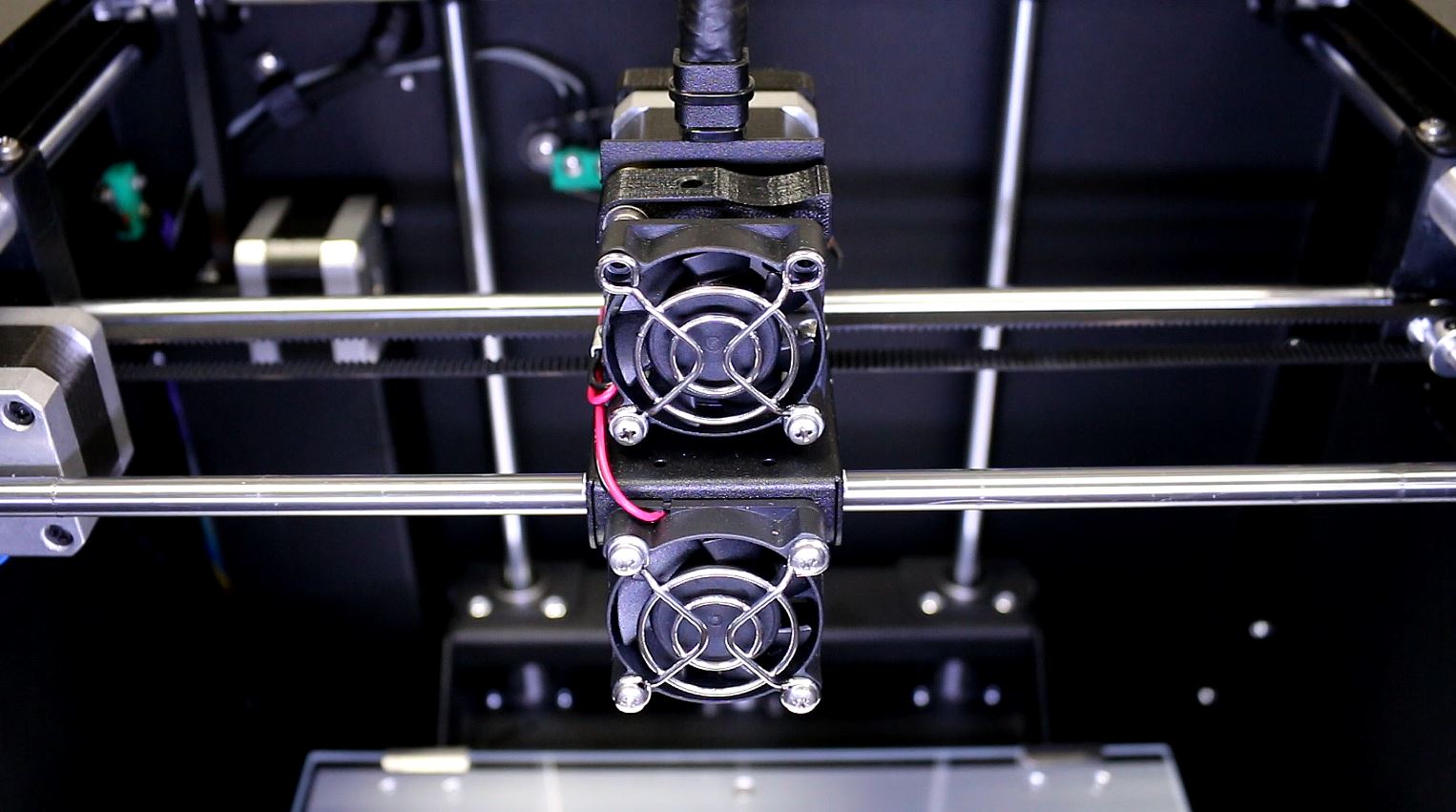

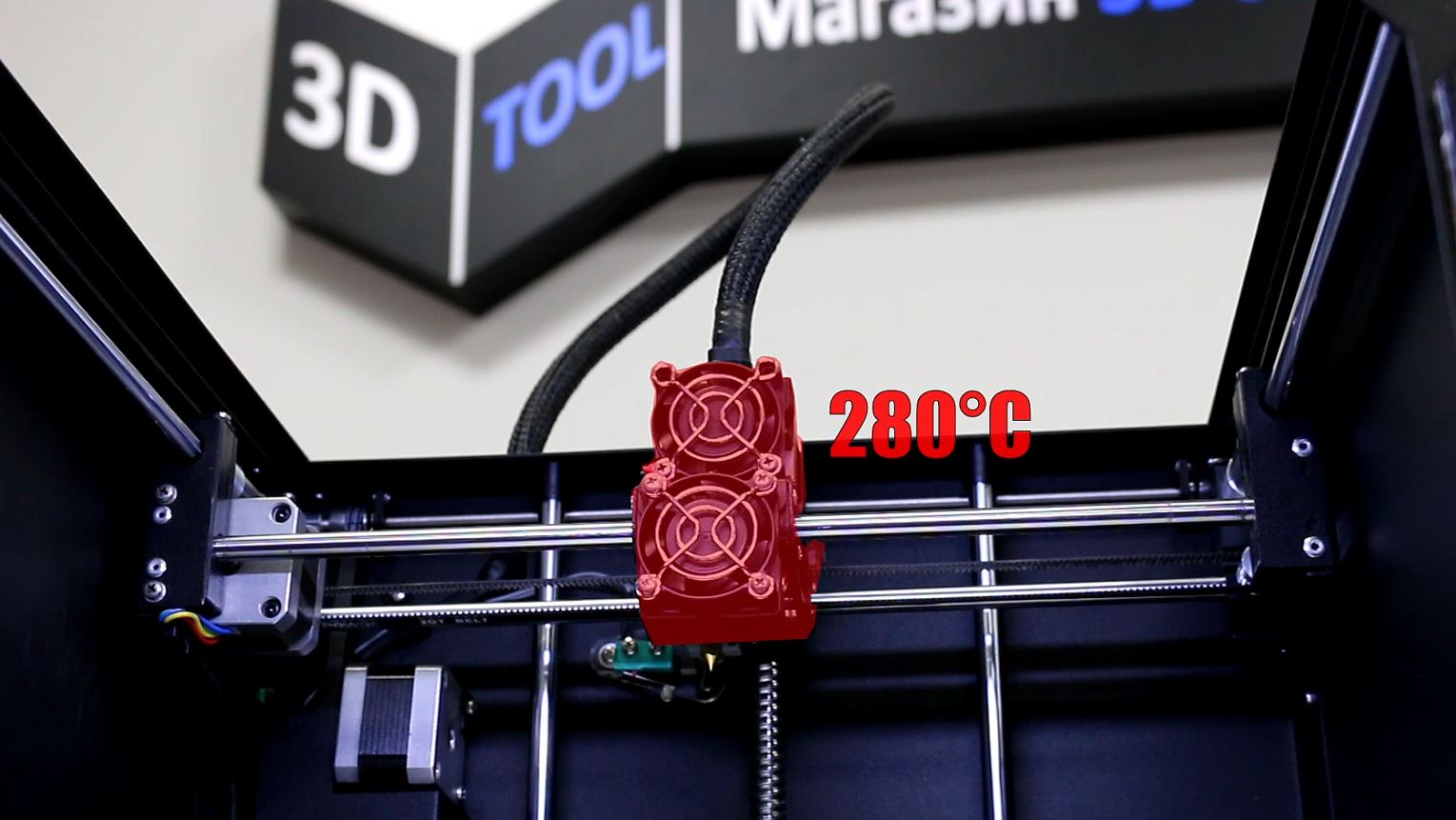

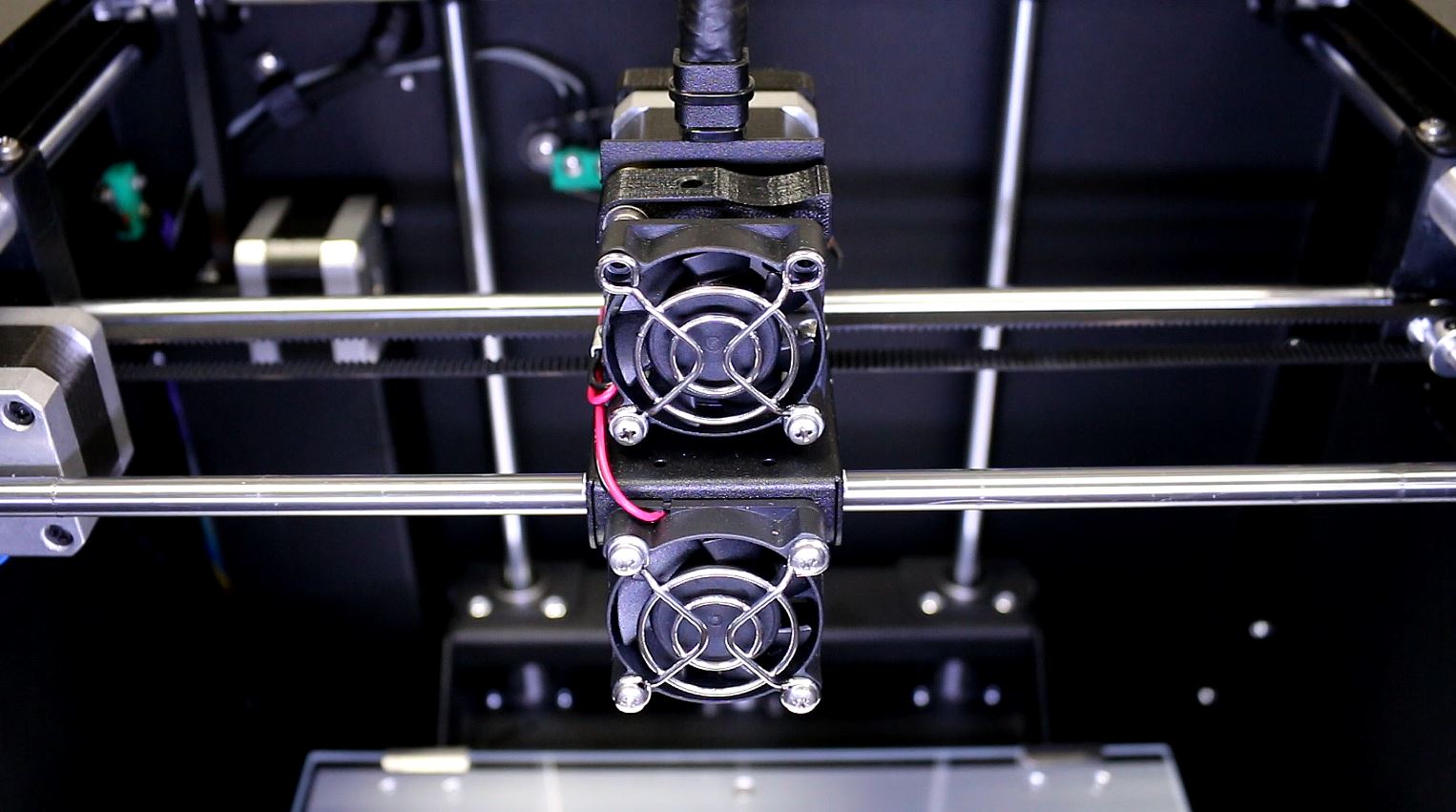

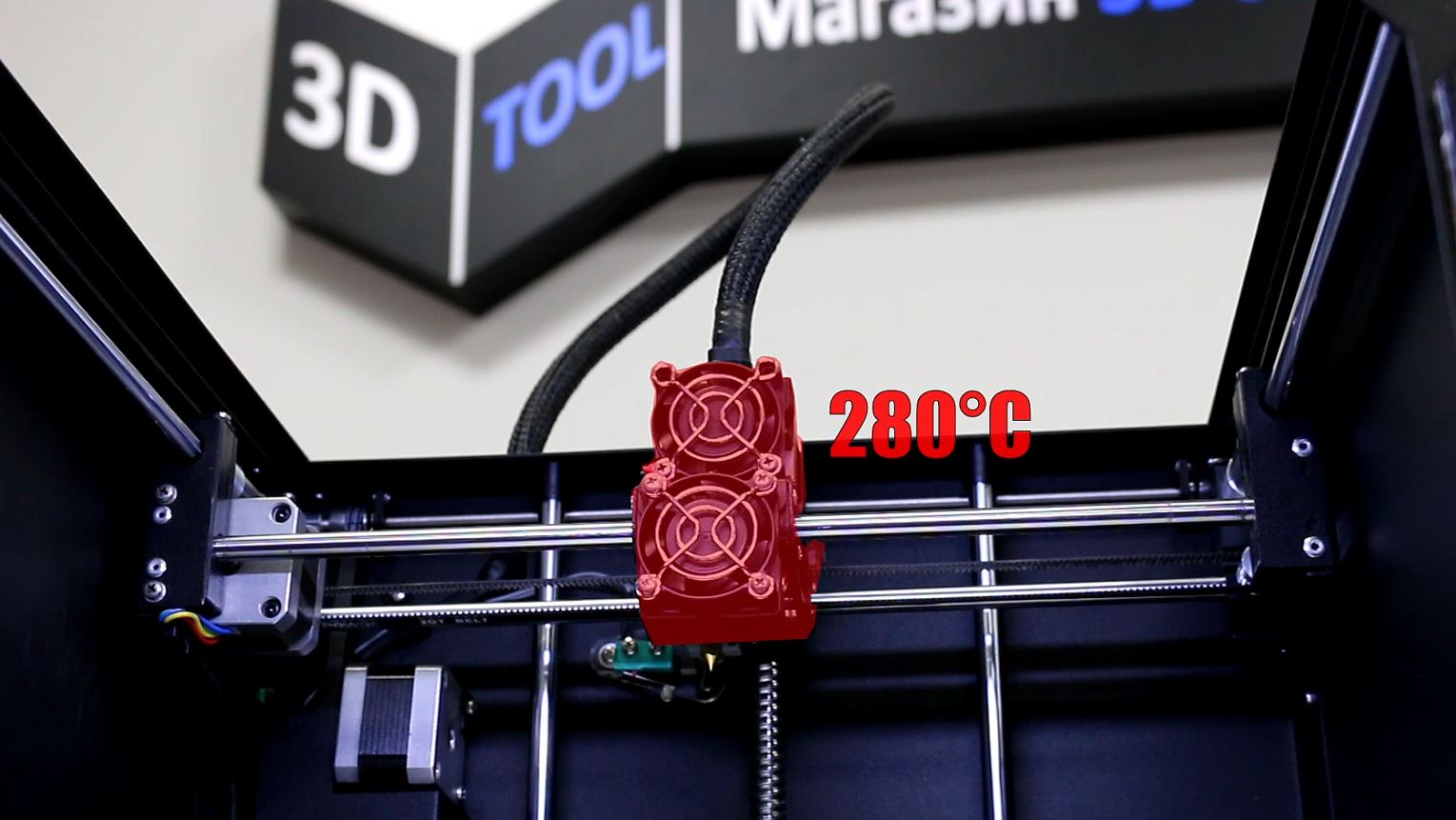

The printer is equipped with a direct extruder, which means that there are no problems with rubber-like plastics. The extruder has an efficient cooling system that does an excellent job with PLA-like plastics. There are no restrictions on the list of materials used. It should also be noted that the extruder heats up to 280 ° C, which allows us to print with materials such as PLA, ABS, Flex and Nylon.

Especially I want to say about the reliability of the extruder (there are no plastic jams - from the word at all). This is achieved through the thread pulling mechanism, developed by the manufacturer Zenit3D. It works stably like a clock. This is an extremely critical parameter for long-term 3D printing.

The diameter of the nozzle installed in the extruder is 0.3 mm.

The maximum print speed of a regular nozzle is 35 cm3 per hour. With all this, the maximum speed of movement of the printhead is 300 mm / sec.

The thickness of the layer along the Z axis is adjusted by settings and ranges from 50 to 250 microns.

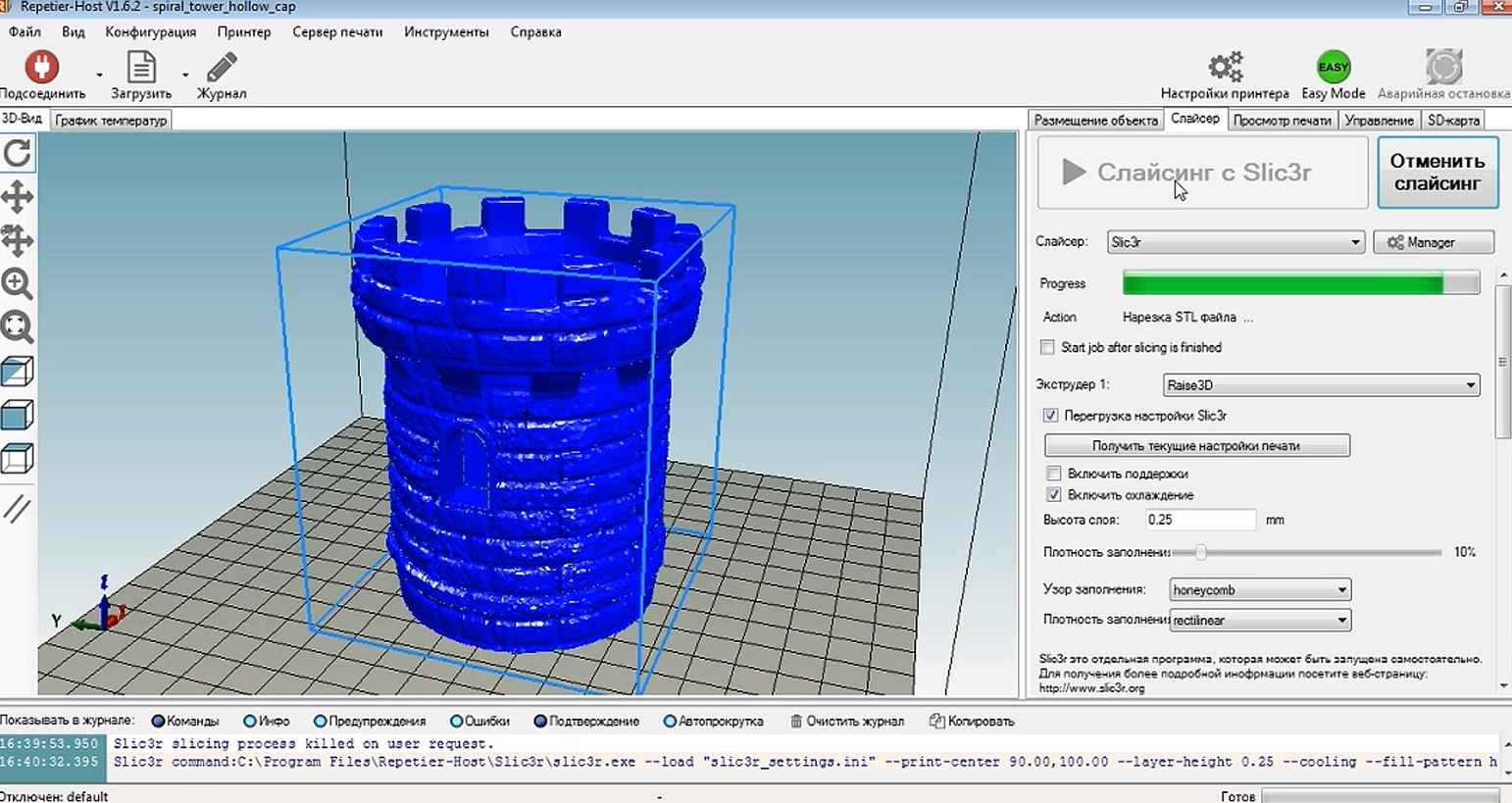

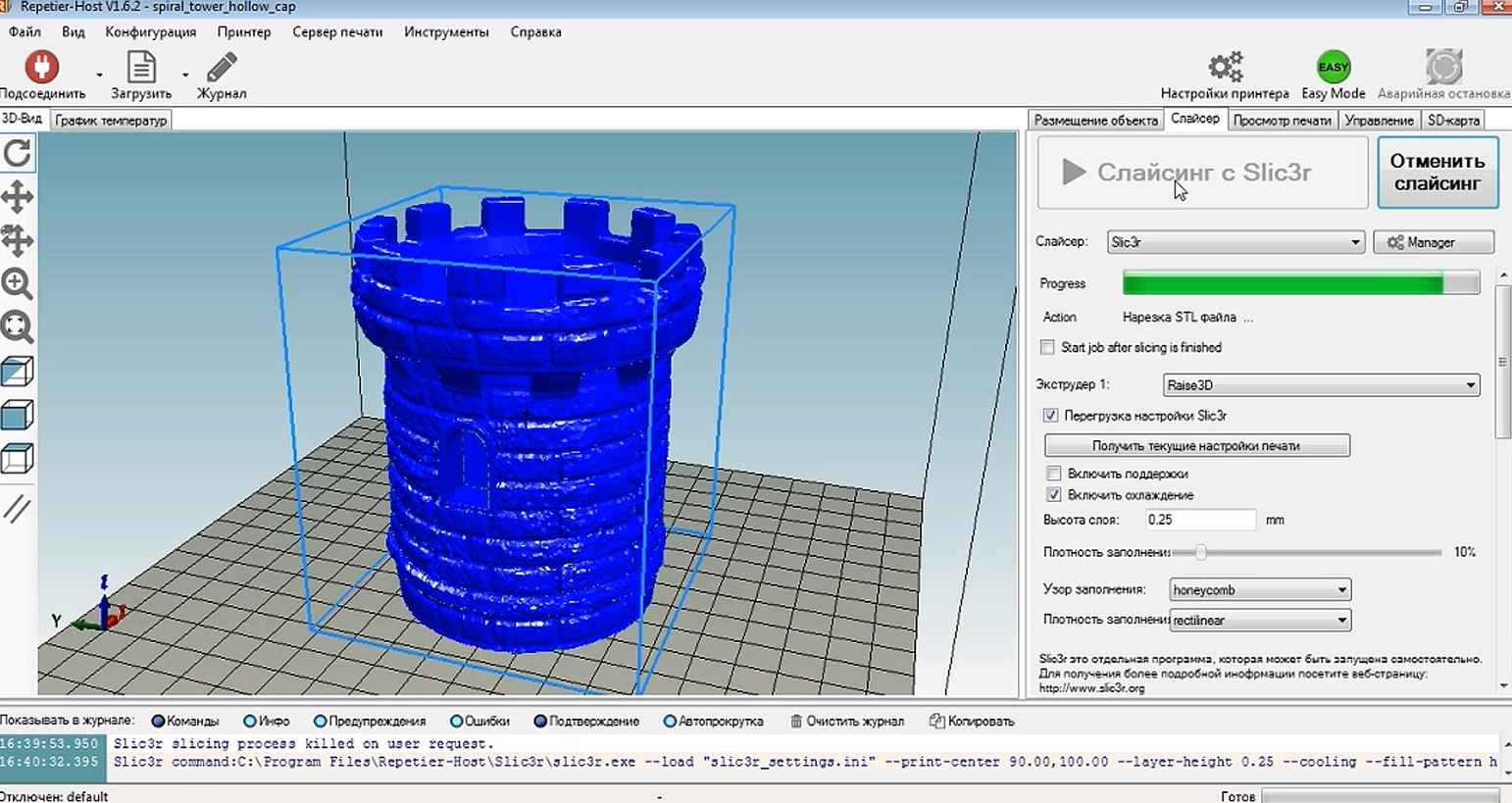

Software (Repetier-Host) for a 3D printer is free. With this software, you can import files in STL format, for later sending a 3D model to print. The program allows you to change the scale, and produce all sorts of manipulations with the 3D model on the plane.

Printer assembly at a very high level. For all the time sales of 3D printers Zenit in our company, and this is about 90 machines per year, there was not a single case of printer failure during the acceptance testing phase of the plant. Believe it is a very cool quality indicator.

Zenit 3D printer can work either from a computer via a USB cable, or offline via an SD card.

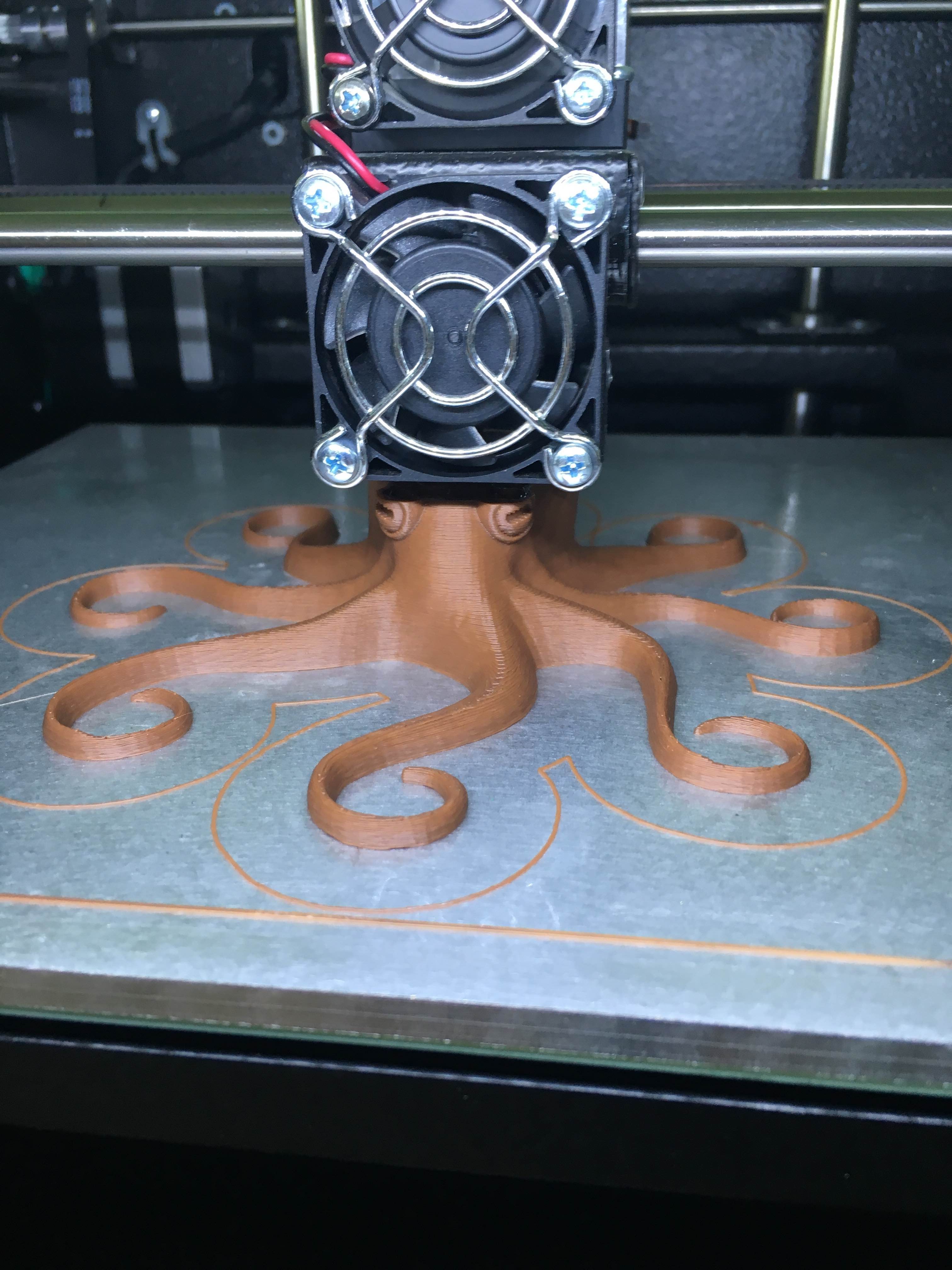

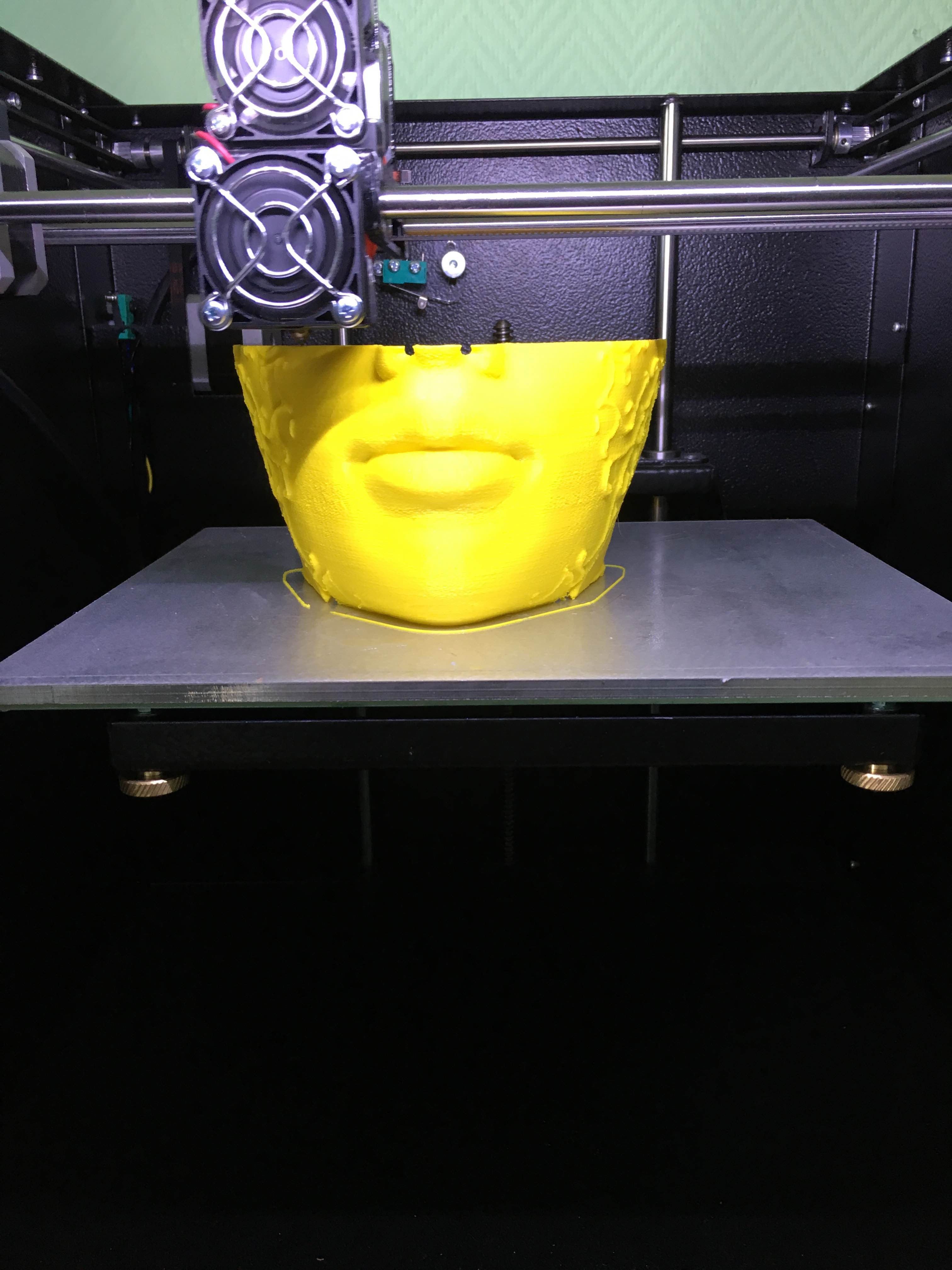

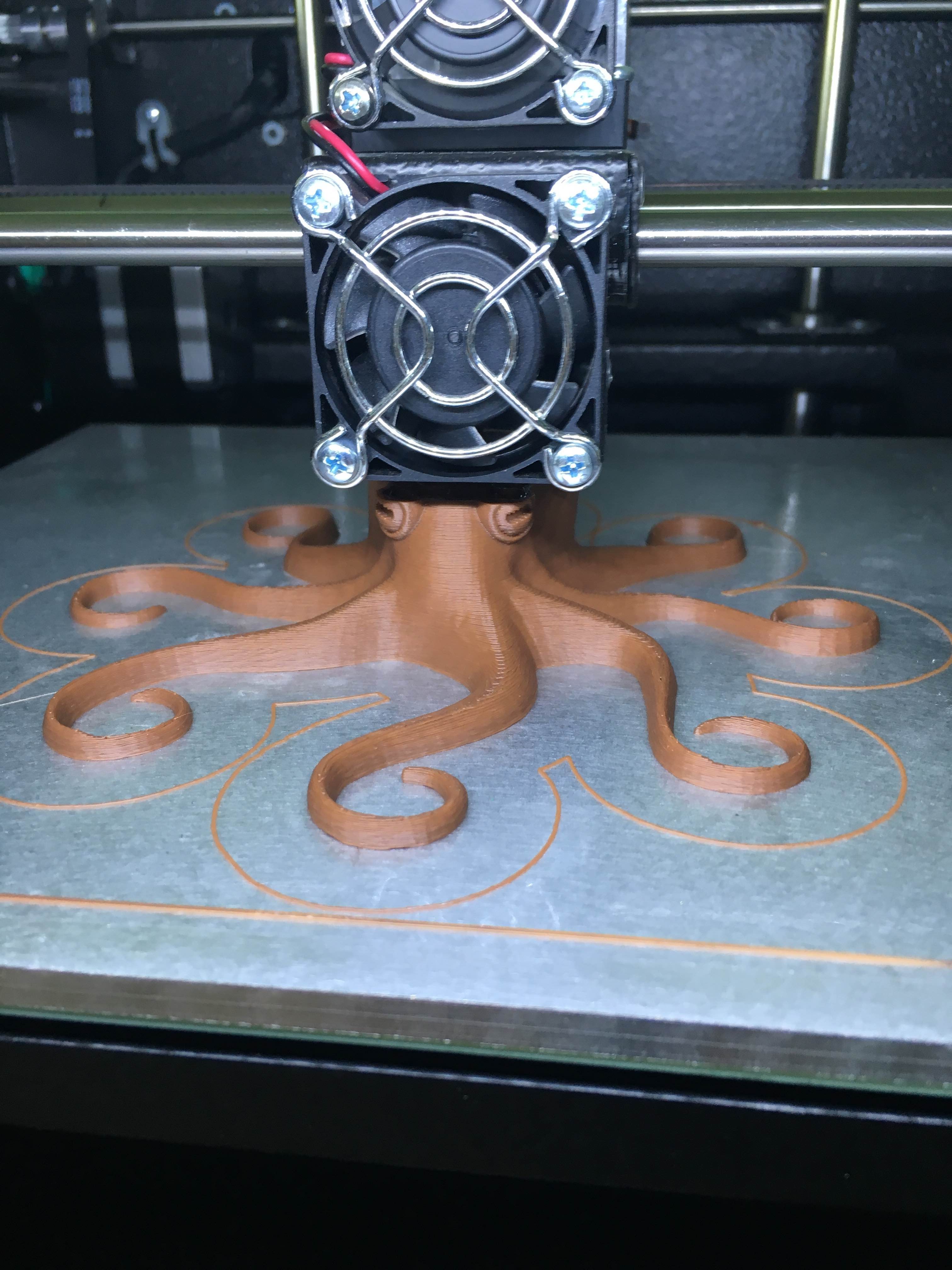

Print

Well, now let's see how the printer behaves in work.

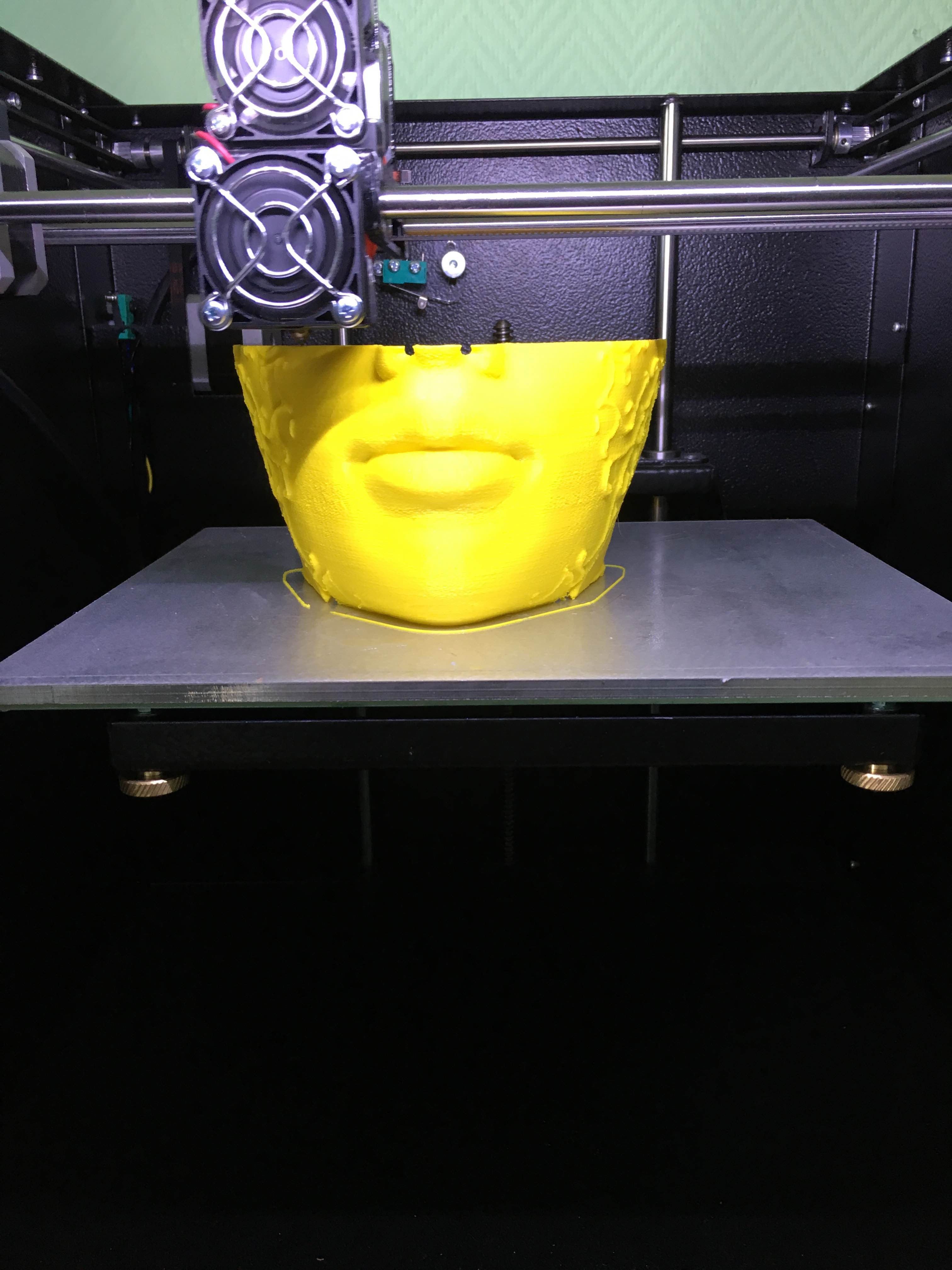

Print quality at a decent level, and the printer during printing is almost inaudible. What is especially important when working at home or in the office.

Zenit is a good answer to its competitors. Value for money is leading in its niche, and the reliability that this printer possesses pleases. We would recommend using this printer to various schools, universities, engineers, and 3D printing workshops.

And you can purchase a Zenit 3D printer in our company's office, by the way, we are the official distributor of Zenit 3D, as evidenced by the certificate.

In addition to the text review, please watch the video review with lots of additional information about the printer (recommended).

Driven by the desire to give a competitive response to similar Russian and Western developments, having spent many months on implementation and testing. At the end of 2015, Zenit3D presented its own 3D printer with the same name Zenit.

In total there are 2 versions of this printer: This is Zenit, which we describe in this review, and Zenit DUO, which is characterized by the presence of two extruders. But first things first.

Appearance

The first thing we see is a metal case that provides vibration resistance. The weight of the printer is about 20 kg.

On the front side of the printer, there is a transparent door of acrylic for easy monitoring of 3D printing and access to the working chamber.

The top of the 3D printer is not closed. Since the plastic for the printer is charged in the upper part of the extruder, it is convenient.

The plastic coil stand is a separate design. It comes with the printer included.

Control screen

Also, the printer has a LCD display on the front panel, which makes its use convenient and ergonomic. Fully Russian-language interface. Management through the rotating joystick. Due to this, during printing we can control the printer and track parameters without being connected to a computer.

Desktop

Now look inside.

Open the door and immediately see the heated desk, made of aluminum, and for greater convenience there is also a removable glass.

There is also an indication of the heating of the table when it is cold, the inscription ZENIT glows blue,

and when the temperature rose to working — red.

The table itself heats up in less than 2 minutes, and its maximum temperature is 110 ° C.

The maximum part size that can be printed in this printer is 240x215x230 mm, and the minimum layer height along the Z axis is 50 microns, which shows us about the large ambitions of this printer.

Zenit 3D printer calibration is performed in manual mode with the help of screws under the desktop, which just adjust the distance between the nozzle and the table. All you have to do is to hold your hand through an extruder at 5 points on the desktop.

Kinematics

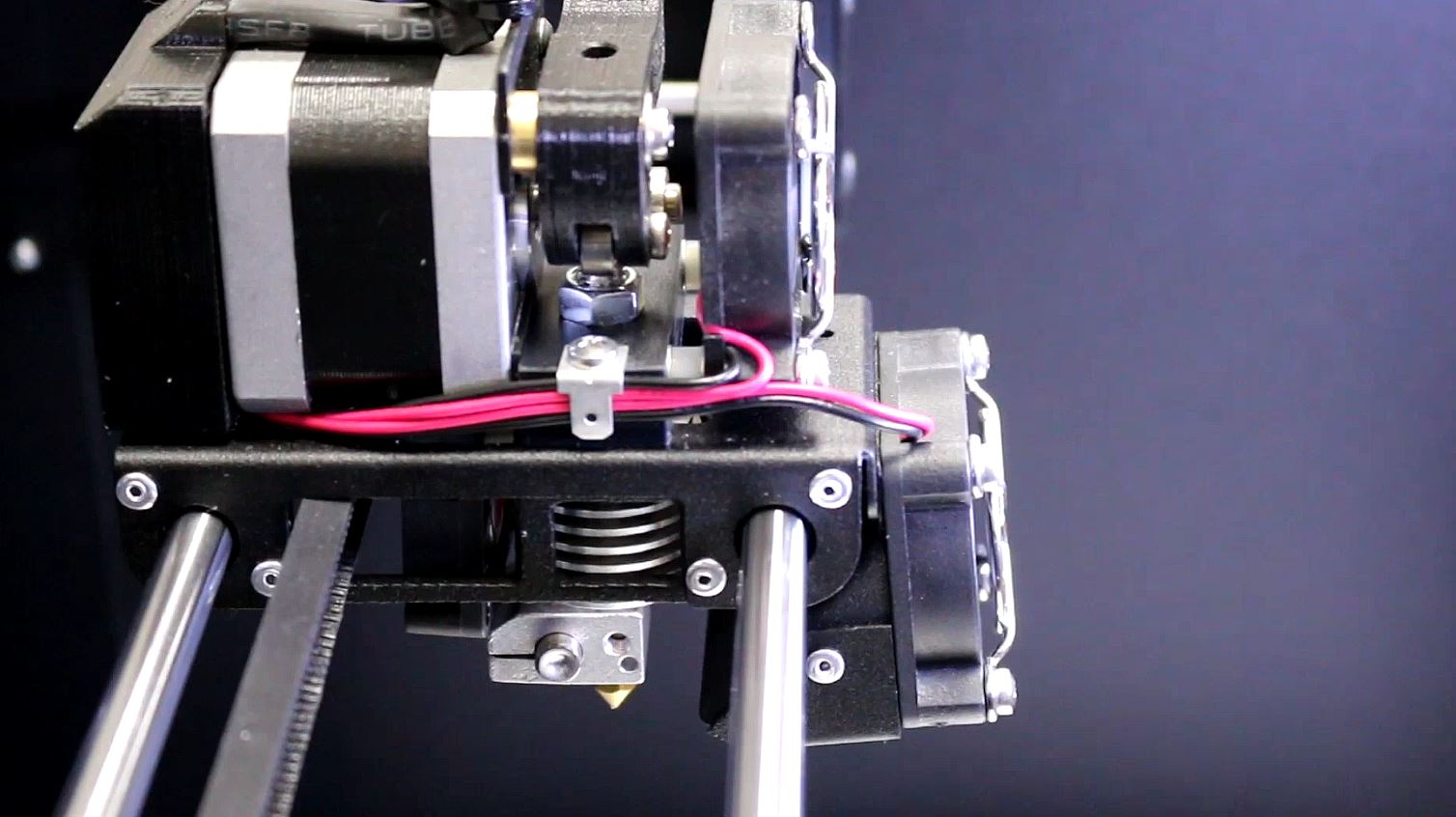

The Z axis uses a ball screw (installed on all printers from the end of 2016) and double 10 mm shafts.

Axes X and Y have shafts with a diameter of 8 mm. The mechanics of the printer is driven by stepping motors through a toothed belt.

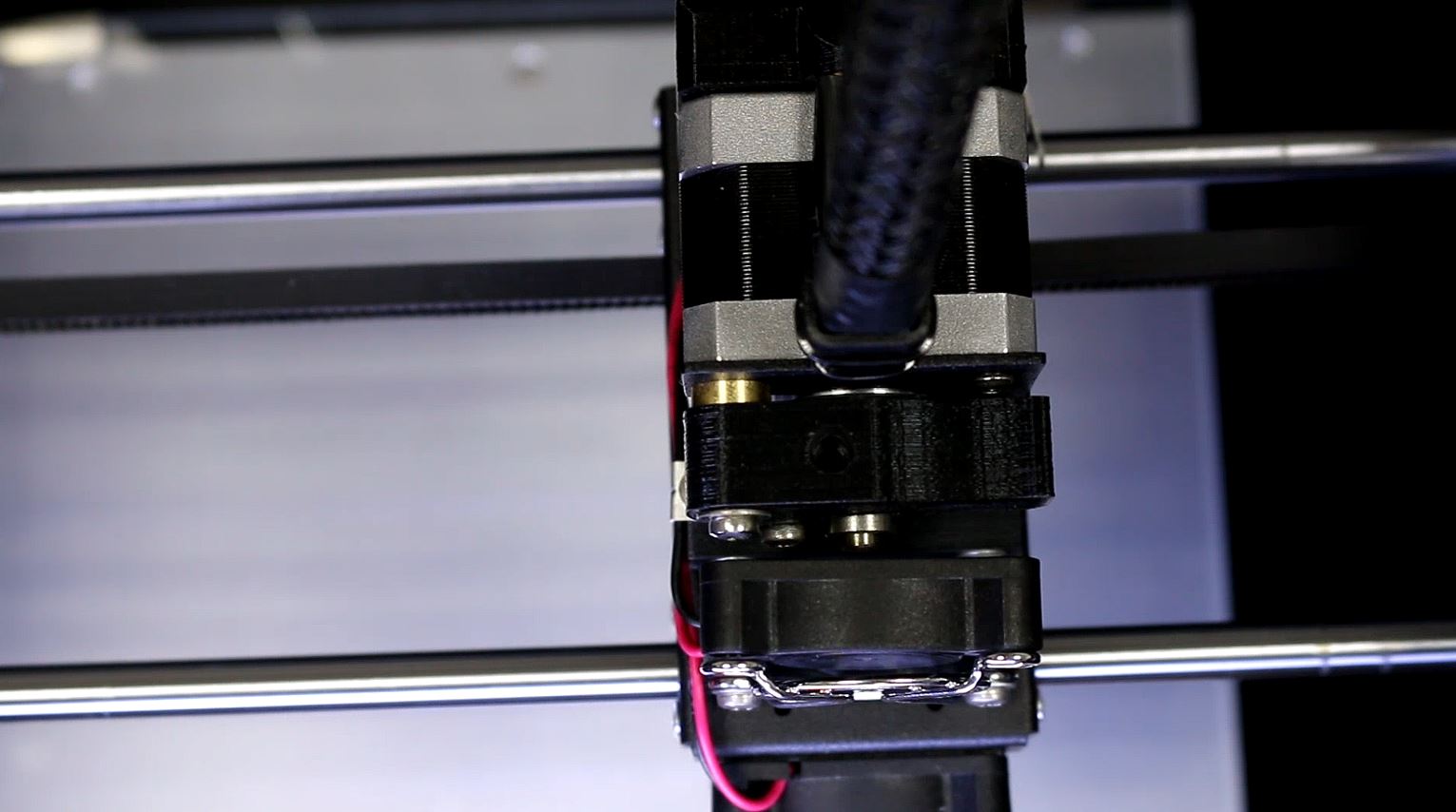

Extruder

The printer is equipped with a direct extruder, which means that there are no problems with rubber-like plastics. The extruder has an efficient cooling system that does an excellent job with PLA-like plastics. There are no restrictions on the list of materials used. It should also be noted that the extruder heats up to 280 ° C, which allows us to print with materials such as PLA, ABS, Flex and Nylon.

Especially I want to say about the reliability of the extruder (there are no plastic jams - from the word at all). This is achieved through the thread pulling mechanism, developed by the manufacturer Zenit3D. It works stably like a clock. This is an extremely critical parameter for long-term 3D printing.

The diameter of the nozzle installed in the extruder is 0.3 mm.

The maximum print speed of a regular nozzle is 35 cm3 per hour. With all this, the maximum speed of movement of the printhead is 300 mm / sec.

The thickness of the layer along the Z axis is adjusted by settings and ranges from 50 to 250 microns.

Software

Software (Repetier-Host) for a 3D printer is free. With this software, you can import files in STL format, for later sending a 3D model to print. The program allows you to change the scale, and produce all sorts of manipulations with the 3D model on the plane.

Printer assembly at a very high level. For all the time sales of 3D printers Zenit in our company, and this is about 90 machines per year, there was not a single case of printer failure during the acceptance testing phase of the plant. Believe it is a very cool quality indicator.

Zenit 3D printer can work either from a computer via a USB cable, or offline via an SD card.

Well, now let's see how the printer behaves in work.

Print quality at a decent level, and the printer during printing is almost inaudible. What is especially important when working at home or in the office.

Summing up, let's highlight the advantages of a Zenit 3D printer:

- The first undoubted advantage is the size of the working area, which is more than competitors, in this price category.

- Extruder design and reliability

- Noiselessness in work.

- Warranty 3 years, and operational Tech. Support.

Zenit is a good answer to its competitors. Value for money is leading in its niche, and the reliability that this printer possesses pleases. We would recommend using this printer to various schools, universities, engineers, and 3D printing workshops.

And you can purchase a Zenit 3D printer in our company's office, by the way, we are the official distributor of Zenit 3D, as evidenced by the certificate.

All Articles