Overview of CNC milling machine Advercut 1212

Today in our review we will tell and show the Advercut K30MT / 1212 CNC milling machine.

Who does not want to read the text review, please watch the video review with a lot of additional visual information about the machine:

The Advercut K30MT / 1212 is a CNC milling machine. Advercut machines are more than 30 models for various tasks of business and production. The plant is located in China, the production is certified by ISO standards, which indicates a high level of assembly and production control at the international level.

In our review, we will focus on the machine Advercut model K30MT / 1212. This is the most affordable machine from the professional line. The machine possesses very serious technical characteristics and is deservedly popular with specialists.

The Advercut K30MT / 1212 is a portal-type CNC milling machine with a working field of 1200 x 1200 x 200 mm.

The weight of the machine reaches 900 kg, which gives a good base, and as a result, ensures good vibration resistance and rigidity.

The size of the working area is 1200 mm by 1200 mm. This can be understood from the name of the machine K30MT / 1212. The machining height along the Z axis is 200 mm. Optionally, you can order a machine with a height of processing up to 300 mm. The machine is primarily focused on wood processing, composite materials and light metals.

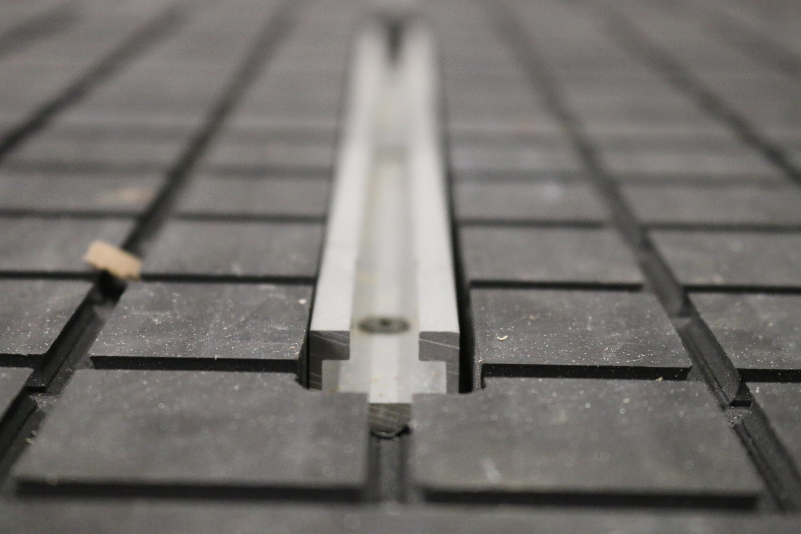

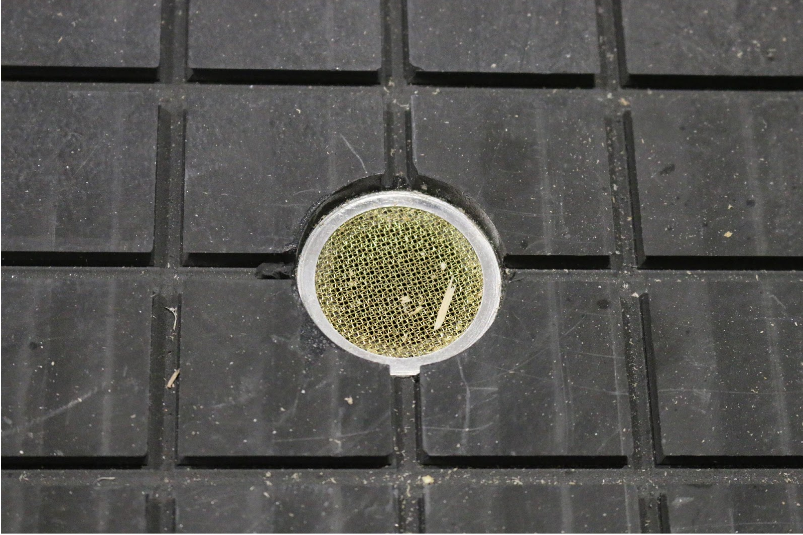

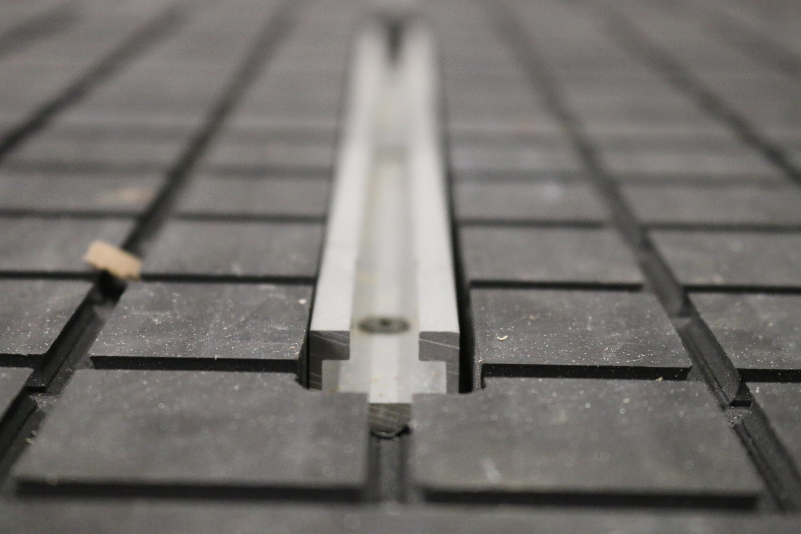

The Advercut K30MT / 1212 milling machine is completed with a vacuum worktable with T-slots. It is a universal solution for any task. Whether it is cutting sheet material, or work with blanks that need to be further strengthened by mechanical fastening to the table with T-slots.

Vacuum clamping, in many cases, speeds up and simplifies production, because saves the operator's time to replace the workpiece and contributes to a better cut when replicating elements.

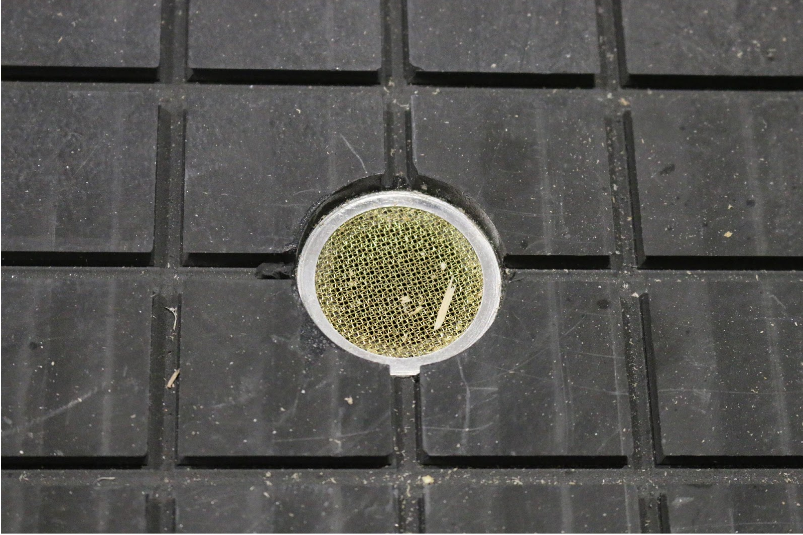

To use a vacuum table, you need a vacuum pump that, through technological openings in the table, sucks air from the cavities between the workpiece and the table, creating a pressure drop, due to which the workpiece is pressed tightly against the table. The effectiveness of the vacuum clamp depends on the characteristics of the vacuum pump used, the tightness of the connections and the characteristics of the workpiece itself.

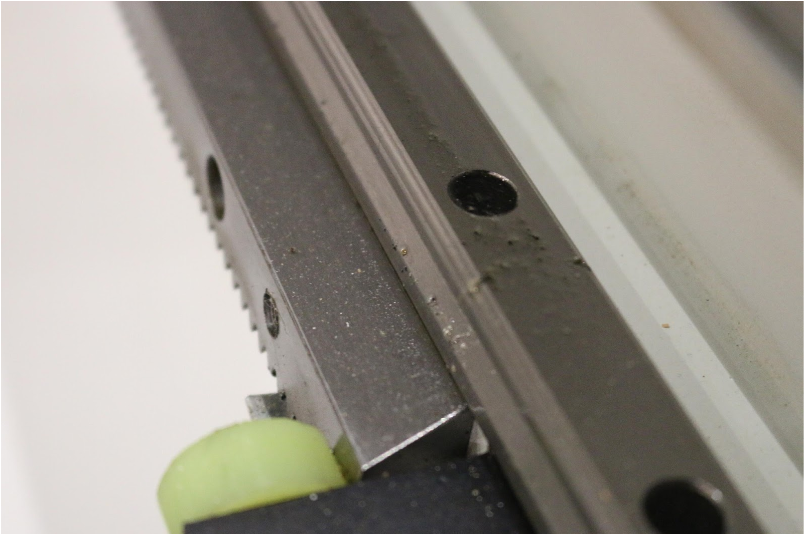

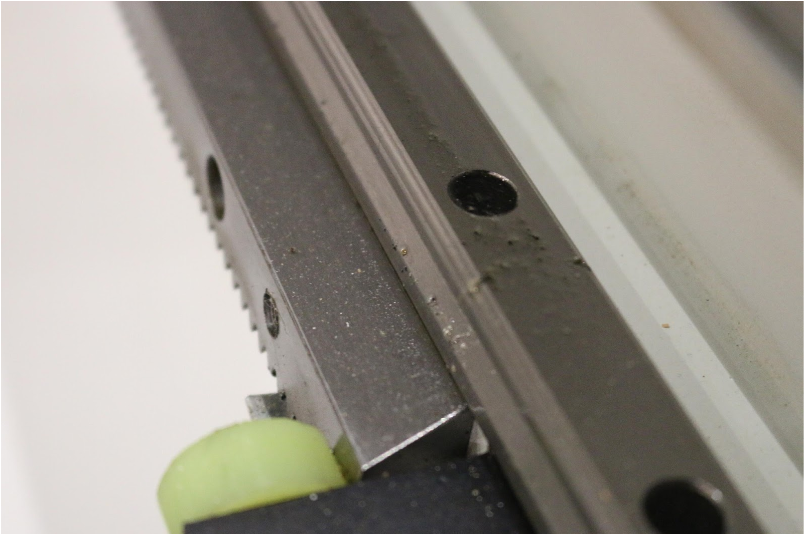

Machine mechanics built on rails. This allows you to achieve a higher accuracy of positioning of the cutter and the quality of processing. Currently, the declared accuracy is 0.05 mm. Used rail guides manufactured in Taiwan

As a drive in X and Y axes, Stepper motors are used with transmission by means of a toothed rack. This solution allows to achieve significant speeds of movement of the portal and 2-3 times faster than similar models on ballscrews.

Used helical raika made in Taiwan.

The machine in the basic configuration is equipped with a centralized lubrication system, which greatly simplifies its maintenance. There is no need to manually lubricate each node of the machine, since the lubricant in all mechanisms comes centrally through a common feed system.

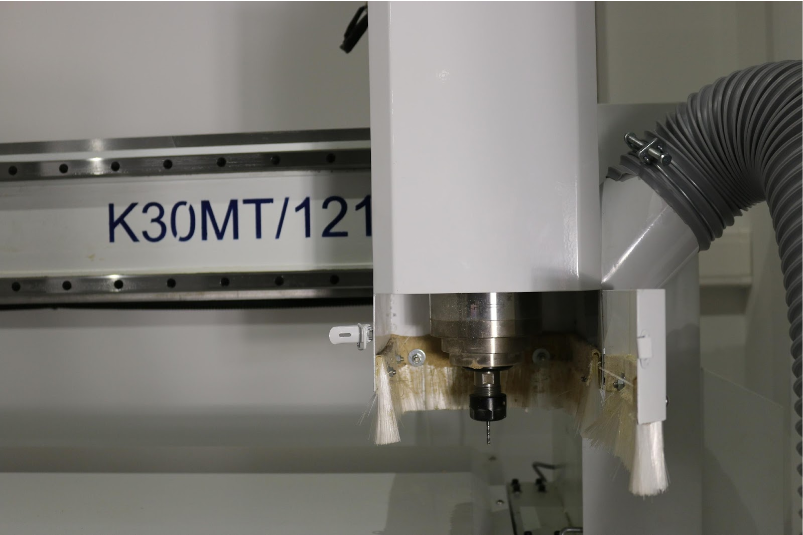

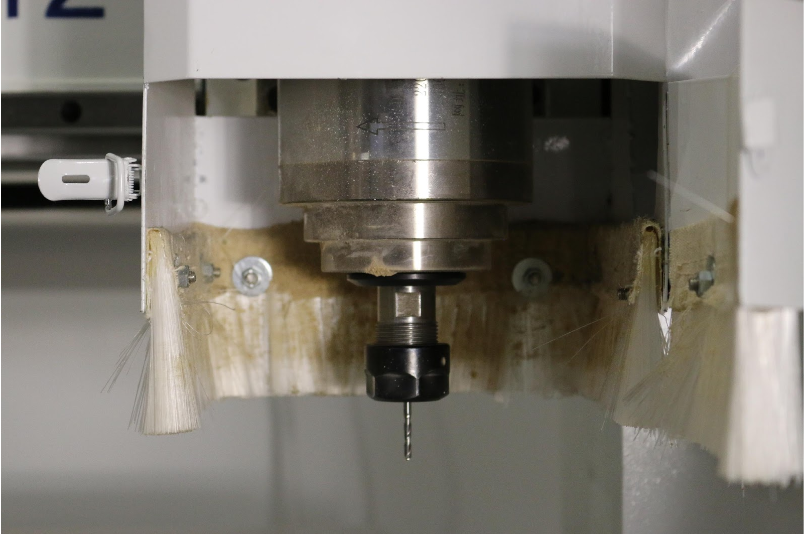

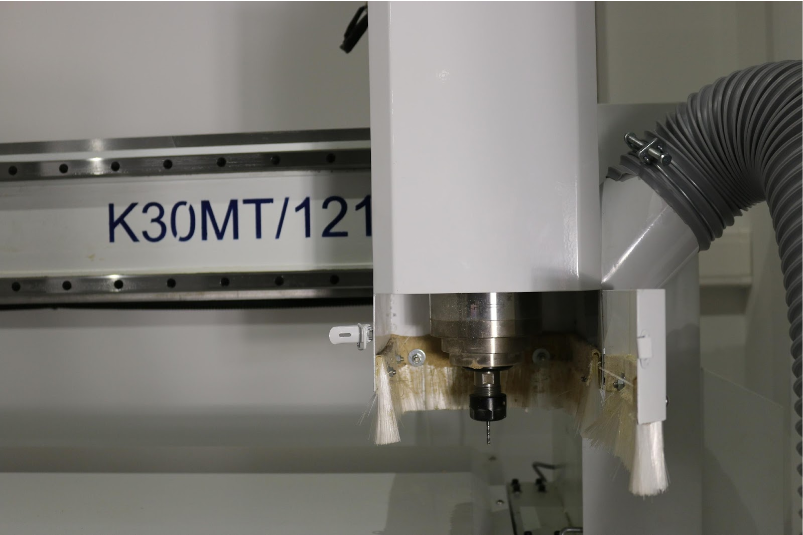

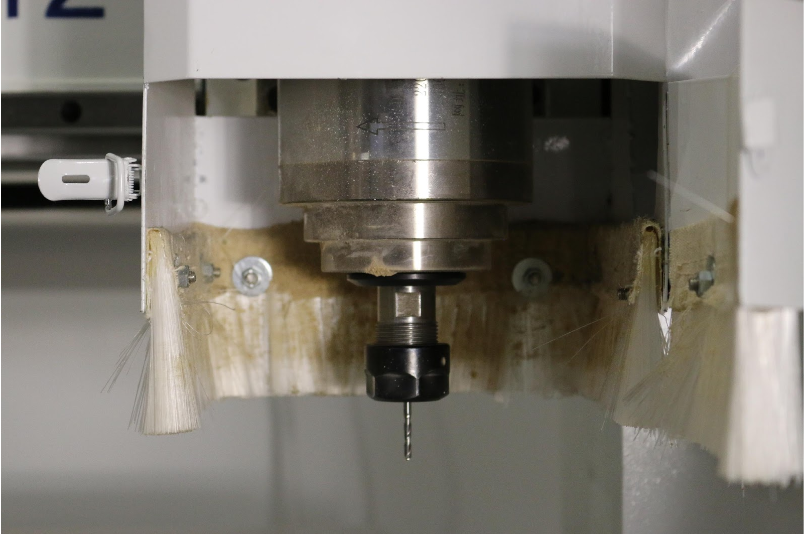

The Advercut K30MT / 1212 is equipped with a 3000 W spindle, which can output up to 24,000 revolutions per minute. It is enough for high-quality processing of wood and plastics, lightweight materials. The spindle has water cooling, which allows to avoid overheating, and provides almost round-the-clock operation with interruptions in service and maintenance. It is also worth noting that the water-cooled spindle is much quieter than with air cooling. Optionally, this machine can be installed even more powerful spindle.

The machine is equipped with a special nozzle on the spindle, which ensures the effective removal of chips from the cutting area. It remains only to connect the corrugation from the aspiration unit to it.

The spindle is equipped with an ER20 collet chuck. Depending on the collet used, this allows you to install a cutting tool (cutter) with a shank diameter of up to 13 mm. Included with the machine are three collet size 3.175, 6, 8, as well as a starting set of cutters, allowing you to immediately start working with the machine.

The machine in the basic configuration is equipped with a workpiece height sensor.

Control is performed using the RichAuto A11 DSP controller. The A11 controller is a compact, stand-alone software and hardware system based on a DSP processor that provides a full cycle of working with the machine: drive control, monitoring program execution, as well as response to sensors and other states of the machine nodes.

The controller reads files from internal memory or an external USB drive and converts program codes into motor control signals. The A11 DSP controller has come a long way of development and today it is the most used controller on industrial grade machines.

Thanks to the autonomous controller, a separate computer in the production room is not required to control the machine; the operator starts the task from a regular USB flash drive. Due to its compactness, the operator can move around the working area of the machine, exercising control and direct visual control during positioning and processing of the product.

The programs themselves for processing can be prepared in almost any compatible software. Such as Artcam, MasterCAM, VisualCAM, SprutCAM, etc.

The machine allows you to mill, drill, cut, engrave wood blanks, composite materials and light metals.

Let's sum up what the Advercut K30MT / 1212 CNC milling machine is good at:

1) Competitive Price Offer

2) Reliable kinematic scheme

3) Rigidity and vibration resistance (weight 900 kg)

4) Reliable and powerful spindle

5) Helical gear and powerful drives

6) Centralized lubrication system

7) Compact stand-alone DSP controller, vacuum table, workpiece height sensor as standard, dust collector attachment (by the way, the workpiece height sensor could be viewed separately in the video, showing how it works)

8) Wide selection of additional options for the machine

9) Availability of equipment in a warehouse in Moscow.

10) Warranty (1 year) and post-warranty support.

You can purchase machine tools and get advice on all issues of interest on Advercut machines in our company 3tool .

Who does not want to read the text review, please watch the video review with a lot of additional visual information about the machine:

The Advercut K30MT / 1212 is a CNC milling machine. Advercut machines are more than 30 models for various tasks of business and production. The plant is located in China, the production is certified by ISO standards, which indicates a high level of assembly and production control at the international level.

In our review, we will focus on the machine Advercut model K30MT / 1212. This is the most affordable machine from the professional line. The machine possesses very serious technical characteristics and is deservedly popular with specialists.

The Advercut K30MT / 1212 is a portal-type CNC milling machine with a working field of 1200 x 1200 x 200 mm.

The weight of the machine reaches 900 kg, which gives a good base, and as a result, ensures good vibration resistance and rigidity.

The size of the working area is 1200 mm by 1200 mm. This can be understood from the name of the machine K30MT / 1212. The machining height along the Z axis is 200 mm. Optionally, you can order a machine with a height of processing up to 300 mm. The machine is primarily focused on wood processing, composite materials and light metals.

The Advercut K30MT / 1212 milling machine is completed with a vacuum worktable with T-slots. It is a universal solution for any task. Whether it is cutting sheet material, or work with blanks that need to be further strengthened by mechanical fastening to the table with T-slots.

Vacuum clamping, in many cases, speeds up and simplifies production, because saves the operator's time to replace the workpiece and contributes to a better cut when replicating elements.

To use a vacuum table, you need a vacuum pump that, through technological openings in the table, sucks air from the cavities between the workpiece and the table, creating a pressure drop, due to which the workpiece is pressed tightly against the table. The effectiveness of the vacuum clamp depends on the characteristics of the vacuum pump used, the tightness of the connections and the characteristics of the workpiece itself.

Machine mechanics built on rails. This allows you to achieve a higher accuracy of positioning of the cutter and the quality of processing. Currently, the declared accuracy is 0.05 mm. Used rail guides manufactured in Taiwan

As a drive in X and Y axes, Stepper motors are used with transmission by means of a toothed rack. This solution allows to achieve significant speeds of movement of the portal and 2-3 times faster than similar models on ballscrews.

Used helical raika made in Taiwan.

The machine in the basic configuration is equipped with a centralized lubrication system, which greatly simplifies its maintenance. There is no need to manually lubricate each node of the machine, since the lubricant in all mechanisms comes centrally through a common feed system.

The Advercut K30MT / 1212 is equipped with a 3000 W spindle, which can output up to 24,000 revolutions per minute. It is enough for high-quality processing of wood and plastics, lightweight materials. The spindle has water cooling, which allows to avoid overheating, and provides almost round-the-clock operation with interruptions in service and maintenance. It is also worth noting that the water-cooled spindle is much quieter than with air cooling. Optionally, this machine can be installed even more powerful spindle.

The machine is equipped with a special nozzle on the spindle, which ensures the effective removal of chips from the cutting area. It remains only to connect the corrugation from the aspiration unit to it.

The spindle is equipped with an ER20 collet chuck. Depending on the collet used, this allows you to install a cutting tool (cutter) with a shank diameter of up to 13 mm. Included with the machine are three collet size 3.175, 6, 8, as well as a starting set of cutters, allowing you to immediately start working with the machine.

The machine in the basic configuration is equipped with a workpiece height sensor.

Control is performed using the RichAuto A11 DSP controller. The A11 controller is a compact, stand-alone software and hardware system based on a DSP processor that provides a full cycle of working with the machine: drive control, monitoring program execution, as well as response to sensors and other states of the machine nodes.

The controller reads files from internal memory or an external USB drive and converts program codes into motor control signals. The A11 DSP controller has come a long way of development and today it is the most used controller on industrial grade machines.

Thanks to the autonomous controller, a separate computer in the production room is not required to control the machine; the operator starts the task from a regular USB flash drive. Due to its compactness, the operator can move around the working area of the machine, exercising control and direct visual control during positioning and processing of the product.

The programs themselves for processing can be prepared in almost any compatible software. Such as Artcam, MasterCAM, VisualCAM, SprutCAM, etc.

The machine allows you to mill, drill, cut, engrave wood blanks, composite materials and light metals.

Let's sum up what the Advercut K30MT / 1212 CNC milling machine is good at:

1) Competitive Price Offer

2) Reliable kinematic scheme

3) Rigidity and vibration resistance (weight 900 kg)

4) Reliable and powerful spindle

5) Helical gear and powerful drives

6) Centralized lubrication system

7) Compact stand-alone DSP controller, vacuum table, workpiece height sensor as standard, dust collector attachment (by the way, the workpiece height sensor could be viewed separately in the video, showing how it works)

8) Wide selection of additional options for the machine

9) Availability of equipment in a warehouse in Moscow.

10) Warranty (1 year) and post-warranty support.

You can purchase machine tools and get advice on all issues of interest on Advercut machines in our company 3tool .

All Articles