How to protect a gadget from water: background and familiarity with HZO technology

The technology of water repellency and water protection in electronic devices has come a long way: from rubber seals to nanofilms. One of the modern solutions that protect smartphones, tablets and readers from liquids is a special HZO coating that is applied directly to electronic device chips.

Next, we will tell you what water repellent technologies exist today, how HZO stands out against their background and how it protects readers and other gadgets from moisture.

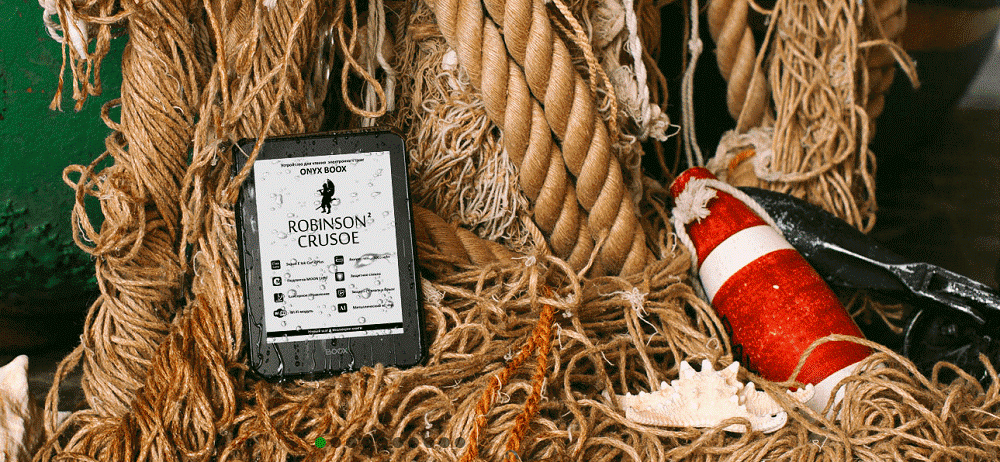

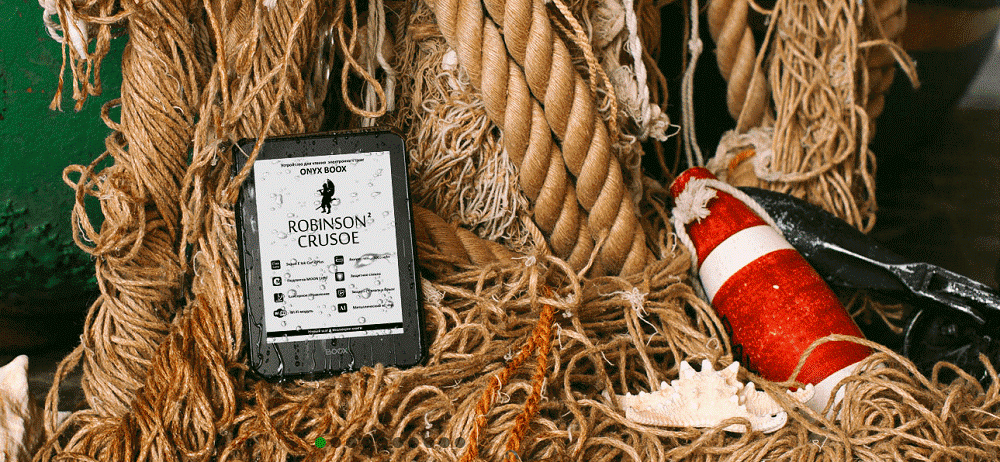

Pictured on ONYX BOOX Robinson Crusoe 2

Before the advent of special chemical compounds, people gave objects hydrophobic properties using natural and natural substances. For example, in order not to let water into the hold and keep the ship afloat, its sides were smeared with tar or tar. Sailors also used various oils, soaking the sails with them to help the fabric withstand the sea winds and heavy rains.

Over time, water-repellent materials have moved into other areas. For example, they began to be used in the textile industry — wax was applied to threads from which waterproof cloaks were sewn.

Also, anti-moisture technologies were used (and used) on paper production for printing topographic maps and reference books with which you can work in adverse conditions. And the technology of creating waterproof paper continues to improve.

For example, a team of scientists led by Dr. Roberto Cingolani (Roberto Cingolani) from the Italian Institute of Technology (IIT) developed water-repellent paper by changing its fibers at the molecular level - each fiber has an individual polymer film. According to the researchers, this paper is no different from the usual at the "philistine level": you can also write, print, etc. on it.

But time does not stand still. Today, humanity has a huge amount of electronic gadgets at its disposal. Smartphones, tablets, readers also require protection from water. According to IDC, water is the cause of smartphone breakdown in 35% of cases, and 100,000 mobile phones in Western Europe “suffer” from water and other liquids every day.

And this is not surprising, since mobile devices have tightly entered our lives, and we carry them with us almost everywhere. Someone even goes with a gadget to the toilet and bathroom. As they say in Dailymail, 75% of people use a smartphone in the toilet, while, according to Plaxo, 19% drop their gadgets into the toilet.

The liquid very quickly gets inside the phone, and the device can “dry” for more than one day. Even if all the moisture evaporates, salts remain on the chips, which corrode the radio elements and can lead to a short circuit on the board. As residents of Reddit note , they react negatively to water and LCD screens. If fluid leaks between the touchscreen and the display, it is more likely to disable the gadget. The other most vulnerable component is the battery. The water that gets inside begins to slowly destroy it from the inside.

And you can not reliably say at what point the effect of corrosion. Rust may begin to actively erode the components of the device within a couple of hours after drowning, on the other hand, signs of a problem may not appear for several days.

Therefore, scientists and manufacturers are working on the creation of technology to protect against moisture. There was even a special standard, the Ingress Protection Rating (IP), defining the degree of protection for the shell. The IP rating system consists of two numbers. The first one indicates the level of protection against the ingress of foreign objects (from 0 to 6), and the second - the level of protection against the ingress of water (from 0 to 9).

The higher the number, the better the protection. IP68 means that the device is completely protected from dust and can be immersed to a meter depth for 30 minutes. To date, this level of protection has flagship smartphone models, for example, Samsung Galaxy S7 / S8 and iPhone 8, and some electronic readers (Kobo Aura H2O).

One of the first solutions to protect electronic components were mechanical plugs and gaskets made of rubber and plastic. For example, special foamed silicone seals were used in the iPhone 6s and SE models - they framed important components of the board.

However, this approach did not make these devices 100% waterproof. Seals do not last forever, and any change in temperature or pressure causes them to expand or contract, disrupting leaks. Depressurization can also be caused by the fall of the device and its contamination.

For example, Sony stresses that the most important condition for using their “waterproof” phones is the presence of all necessary plugs at the openings. If the watertight diagnostics show that moisture gets inside the device due to loose plugs (in other words, if during tests it turns out that tightly closed plugs do not allow water to seep inside), the device is removed from the guarantee due to “violations of operation” .

By the way, a case with “waterproofness” can cost Sony money - in August of this year, a federal court in New York approved a lawsuit against Sony Mobile Communications (USA) Inc. and Sony Electronics Inc. In court, they considered that the company's statements about the "water resistance" of a number of Sony Xperia models had misled customers. However, only American owners of Sony Xperia damaged by moisture can rely on compensation.

The drawbacks and limitations of the plugs led to the appearance on the market of solutions that are not so heavily dependent on the environment, for example, hydrophobic nano-coatings. However, for the most part, such coatings act as a splash guard, since (as a rule) they are not completely waterproof and wear out over time. At full immersion, the water still begins to seep through the "protective barrier". For example, in this video , a smartphone with a hydrophobic coating Liquipel "lived" under water for only 10 seconds longer than a device without protection.

Therefore, the technology went further. Appeared so-called conformal coatings. A special film of acrylic, polyurethane, epoxy, silicone or parylene " covers " the chip, protecting the device from moisture and preventing corrosion. One of the companies developing this technology is HZO.

In the company HZO for protection of microcircuits are used steam rooms. The polymer coating is applied using the method of chemical deposition from the gas phase in special vacuum installations. The microcircuits are placed in vapor pairs, which, reacting, form a protective coating on the surface of the circuits.

Components that do not have to be under a protective film (for example, electrical contacts and connections) are covered with a special insulating layer - they are masked . At the end of the chemical precipitation process, they are unmasked.

The technology makes it possible to obtain a uniform coating with a thickness of 5–10 µm without breaks with high moisture resistance and penetration resistance properties according to the IPX8 standard .

The advantage of HZO technology over standard methods like seals is also that the slots in the case do not interfere with protection against moisture - on the contrary, water can freely flow out of the device through them without causing harm to it. But with seals everything is different - if the liquid still gets into the device (due to depressurization), the plugs will only prevent the evaporation of water, "locking" it inside the gadget.

HZO operates in a market valued at $ 7 billion. The development of the sphere goes at an exponential rate, because more and more electronics manufacturers are beginning to turn their attention to technologies that allow them to abandon mechanical plugs and seals.

Today, tablets, such as the Dell Latitude 12, Motorola wireless headphones , and even security cameras that require protection from rain, snow and fog, come with moisture protection from HZO.

No exception and readers. For example, technology HZO protected devices Kobo Aura One. The reader conforms to the IPX8 standard, and, according to the manufacturer, the reader will “ survive ” a dive to a depth of two meters within an hour.

However, the company still notes that if the reader is drowned, it should be taken out of the water as quickly as possible and the moisture should be let out through the holes in the case. In addition, you should not connect the reader to the charger until it is completely dry.

Pictured on ONYX BOOX Robinson Crusoe 2

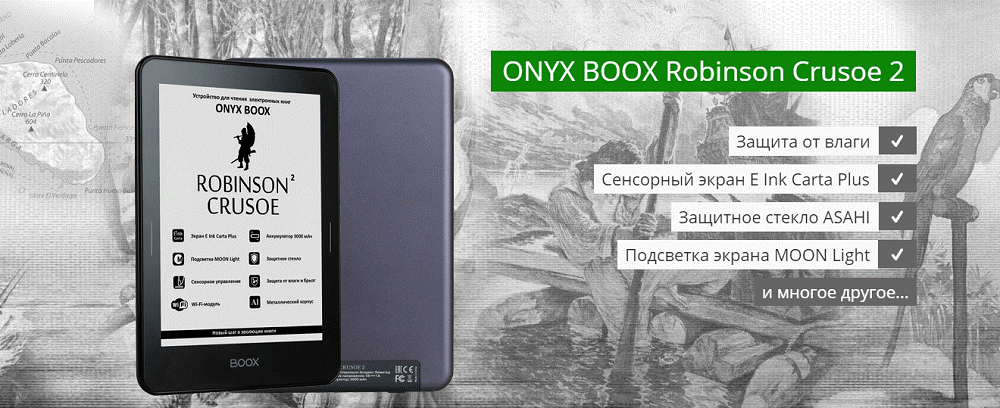

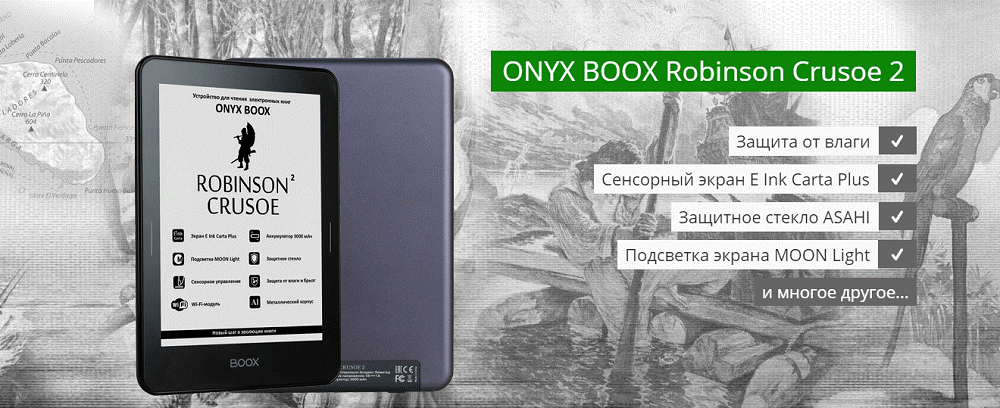

Another family of readers with water protection HZO - ONYX BOOX Robinson Crusoe and ONYX BOOX Robinson Crusoe 2 . The new model Robinson Crusoe 2 is a premium level reader, equipped with an E Ink Carta Plus screen with a MOON Light backlight. The reader is made of high quality materials, has a thin aluminum alloy casing and ASAHI glass that protects against scratches.

Water, getting inside the case of the reader, does not harm metal and electronic components. However, as in the case of Kobo Aura One, if ONYX BOOX Robinson Crusoe 2 fell into the water, it is better to immediately remove the reader and allow the liquid to flow out through the holes and evaporate.

As noted in the company HZO, engineers are trying to extend the technology of moisture protection in as many areas as possible: from wearable gadgets to medical equipment. Therefore, in the future, more and more electronic devices will be made resistant to water and corrosion.

PS This week on our GT blog, we reviewed the ONYX BOOX Robinson Crusoe 2 reader. In it, we introduce you to the device bundle, as well as talk about its “stuffing”.

PPS A few more reviews of the ONYX BOOX readers:

Next, we will tell you what water repellent technologies exist today, how HZO stands out against their background and how it protects readers and other gadgets from moisture.

Pictured on ONYX BOOX Robinson Crusoe 2

The formation of water protection technologies: a bit of history

Before the advent of special chemical compounds, people gave objects hydrophobic properties using natural and natural substances. For example, in order not to let water into the hold and keep the ship afloat, its sides were smeared with tar or tar. Sailors also used various oils, soaking the sails with them to help the fabric withstand the sea winds and heavy rains.

Over time, water-repellent materials have moved into other areas. For example, they began to be used in the textile industry — wax was applied to threads from which waterproof cloaks were sewn.

Also, anti-moisture technologies were used (and used) on paper production for printing topographic maps and reference books with which you can work in adverse conditions. And the technology of creating waterproof paper continues to improve.

For example, a team of scientists led by Dr. Roberto Cingolani (Roberto Cingolani) from the Italian Institute of Technology (IIT) developed water-repellent paper by changing its fibers at the molecular level - each fiber has an individual polymer film. According to the researchers, this paper is no different from the usual at the "philistine level": you can also write, print, etc. on it.

Appearance of electronic devices

But time does not stand still. Today, humanity has a huge amount of electronic gadgets at its disposal. Smartphones, tablets, readers also require protection from water. According to IDC, water is the cause of smartphone breakdown in 35% of cases, and 100,000 mobile phones in Western Europe “suffer” from water and other liquids every day.

And this is not surprising, since mobile devices have tightly entered our lives, and we carry them with us almost everywhere. Someone even goes with a gadget to the toilet and bathroom. As they say in Dailymail, 75% of people use a smartphone in the toilet, while, according to Plaxo, 19% drop their gadgets into the toilet.

The liquid very quickly gets inside the phone, and the device can “dry” for more than one day. Even if all the moisture evaporates, salts remain on the chips, which corrode the radio elements and can lead to a short circuit on the board. As residents of Reddit note , they react negatively to water and LCD screens. If fluid leaks between the touchscreen and the display, it is more likely to disable the gadget. The other most vulnerable component is the battery. The water that gets inside begins to slowly destroy it from the inside.

And you can not reliably say at what point the effect of corrosion. Rust may begin to actively erode the components of the device within a couple of hours after drowning, on the other hand, signs of a problem may not appear for several days.

Therefore, scientists and manufacturers are working on the creation of technology to protect against moisture. There was even a special standard, the Ingress Protection Rating (IP), defining the degree of protection for the shell. The IP rating system consists of two numbers. The first one indicates the level of protection against the ingress of foreign objects (from 0 to 6), and the second - the level of protection against the ingress of water (from 0 to 9).

The higher the number, the better the protection. IP68 means that the device is completely protected from dust and can be immersed to a meter depth for 30 minutes. To date, this level of protection has flagship smartphone models, for example, Samsung Galaxy S7 / S8 and iPhone 8, and some electronic readers (Kobo Aura H2O).

How to protect electronic devices

One of the first solutions to protect electronic components were mechanical plugs and gaskets made of rubber and plastic. For example, special foamed silicone seals were used in the iPhone 6s and SE models - they framed important components of the board.

However, this approach did not make these devices 100% waterproof. Seals do not last forever, and any change in temperature or pressure causes them to expand or contract, disrupting leaks. Depressurization can also be caused by the fall of the device and its contamination.

For example, Sony stresses that the most important condition for using their “waterproof” phones is the presence of all necessary plugs at the openings. If the watertight diagnostics show that moisture gets inside the device due to loose plugs (in other words, if during tests it turns out that tightly closed plugs do not allow water to seep inside), the device is removed from the guarantee due to “violations of operation” .

By the way, a case with “waterproofness” can cost Sony money - in August of this year, a federal court in New York approved a lawsuit against Sony Mobile Communications (USA) Inc. and Sony Electronics Inc. In court, they considered that the company's statements about the "water resistance" of a number of Sony Xperia models had misled customers. However, only American owners of Sony Xperia damaged by moisture can rely on compensation.

The drawbacks and limitations of the plugs led to the appearance on the market of solutions that are not so heavily dependent on the environment, for example, hydrophobic nano-coatings. However, for the most part, such coatings act as a splash guard, since (as a rule) they are not completely waterproof and wear out over time. At full immersion, the water still begins to seep through the "protective barrier". For example, in this video , a smartphone with a hydrophobic coating Liquipel "lived" under water for only 10 seconds longer than a device without protection.

Therefore, the technology went further. Appeared so-called conformal coatings. A special film of acrylic, polyurethane, epoxy, silicone or parylene " covers " the chip, protecting the device from moisture and preventing corrosion. One of the companies developing this technology is HZO.

How does HZO work

In the company HZO for protection of microcircuits are used steam rooms. The polymer coating is applied using the method of chemical deposition from the gas phase in special vacuum installations. The microcircuits are placed in vapor pairs, which, reacting, form a protective coating on the surface of the circuits.

Components that do not have to be under a protective film (for example, electrical contacts and connections) are covered with a special insulating layer - they are masked . At the end of the chemical precipitation process, they are unmasked.

The technology makes it possible to obtain a uniform coating with a thickness of 5–10 µm without breaks with high moisture resistance and penetration resistance properties according to the IPX8 standard .

The advantage of HZO technology over standard methods like seals is also that the slots in the case do not interfere with protection against moisture - on the contrary, water can freely flow out of the device through them without causing harm to it. But with seals everything is different - if the liquid still gets into the device (due to depressurization), the plugs will only prevent the evaporation of water, "locking" it inside the gadget.

Where is HZO used

HZO operates in a market valued at $ 7 billion. The development of the sphere goes at an exponential rate, because more and more electronics manufacturers are beginning to turn their attention to technologies that allow them to abandon mechanical plugs and seals.

Today, tablets, such as the Dell Latitude 12, Motorola wireless headphones , and even security cameras that require protection from rain, snow and fog, come with moisture protection from HZO.

No exception and readers. For example, technology HZO protected devices Kobo Aura One. The reader conforms to the IPX8 standard, and, according to the manufacturer, the reader will “ survive ” a dive to a depth of two meters within an hour.

However, the company still notes that if the reader is drowned, it should be taken out of the water as quickly as possible and the moisture should be let out through the holes in the case. In addition, you should not connect the reader to the charger until it is completely dry.

Pictured on ONYX BOOX Robinson Crusoe 2

Another family of readers with water protection HZO - ONYX BOOX Robinson Crusoe and ONYX BOOX Robinson Crusoe 2 . The new model Robinson Crusoe 2 is a premium level reader, equipped with an E Ink Carta Plus screen with a MOON Light backlight. The reader is made of high quality materials, has a thin aluminum alloy casing and ASAHI glass that protects against scratches.

Water, getting inside the case of the reader, does not harm metal and electronic components. However, as in the case of Kobo Aura One, if ONYX BOOX Robinson Crusoe 2 fell into the water, it is better to immediately remove the reader and allow the liquid to flow out through the holes and evaporate.

As noted in the company HZO, engineers are trying to extend the technology of moisture protection in as many areas as possible: from wearable gadgets to medical equipment. Therefore, in the future, more and more electronic devices will be made resistant to water and corrosion.

PS This week on our GT blog, we reviewed the ONYX BOOX Robinson Crusoe 2 reader. In it, we introduce you to the device bundle, as well as talk about its “stuffing”.

PPS A few more reviews of the ONYX BOOX readers:

All Articles