Industrial robots in business: Kawasaki cases for ITER, DiKom and Lenmontazh

Welding is a laborious and dangerous process, so large companies are beginning to implement robotic complexes at their facilities, refusing manual labor. So, for example, did "DiKom" and "Lenmontazh", replacing human welders with robots from Kawasaki.

Kawasaki Robotics is a Japanese robotic company that manufactures and supplies industrial robots. More than 100 thousand robots installed on various industrial complexes in Europe, Asia, America, Africa, Russia and the Middle East.

According to Kawasaki Robotics Europe’s general marketing and sales manager Karsten Stumpf, it’s better to entrust simple work to the robot , and the person should be creative.

“We believe that robots should co-exist with humans. The most promising direction in robotics, as for me, is the creation of robots with easy learning, ”said Carsten.

Spray Robots and the ITER International Project

The task: to spray a copper coating on flat electrocontact surfaces of aluminum tires for an international project ITER (International Thermonuclear Experimental Reactor).

Executor: the innovative company “Acton”, commissioned by the Research Institute of Electrophysical Equipment named after D.V. Ephraim.

How it was done: Acton built a robotic complex consisting of an OWEN controller, a sputtering chamber, a Kawasaki RS006L robot, and a Kawasaki E01 controller.

The robot itself is a mechanical "arm", at the end of which a gas-dynamic sprayer is installed. It has 6 degrees of freedom, is drawn in length by 1.6 m, has a carrying capacity of 6 kg, and the weight of the apparatus itself is 150 kg.

Kawasaki E01 is a new universal controller with which the robot is controlled and programmed.

More about the project

“The machine does not consume much energy compared to welding equipment or spraying equipment. Peak RS006L consumption is 5.6 kV · A at the time of launch: the robot is turned on and the capacitors in the controller start charging. Later, he works in a more “quiet” mode in terms of power consumption, ”explained Roman Timofeev, a representative of Robowizard , the official distributor of Kawasaki Robotics in Russia.

ITER is an international project to create an experimental thermonuclear reactor, which is being implemented in France. Scientists from the EU, China, Korea, USA, Japan and Russia take part in it.

Furniture production for "DiKoma"

Objective: to expand the model lines of instrumental stands and improve the quality of the product.

Contractor: FAM Robotics, commissioned by DiCom, is a manufacturer of metal furniture and shelving.

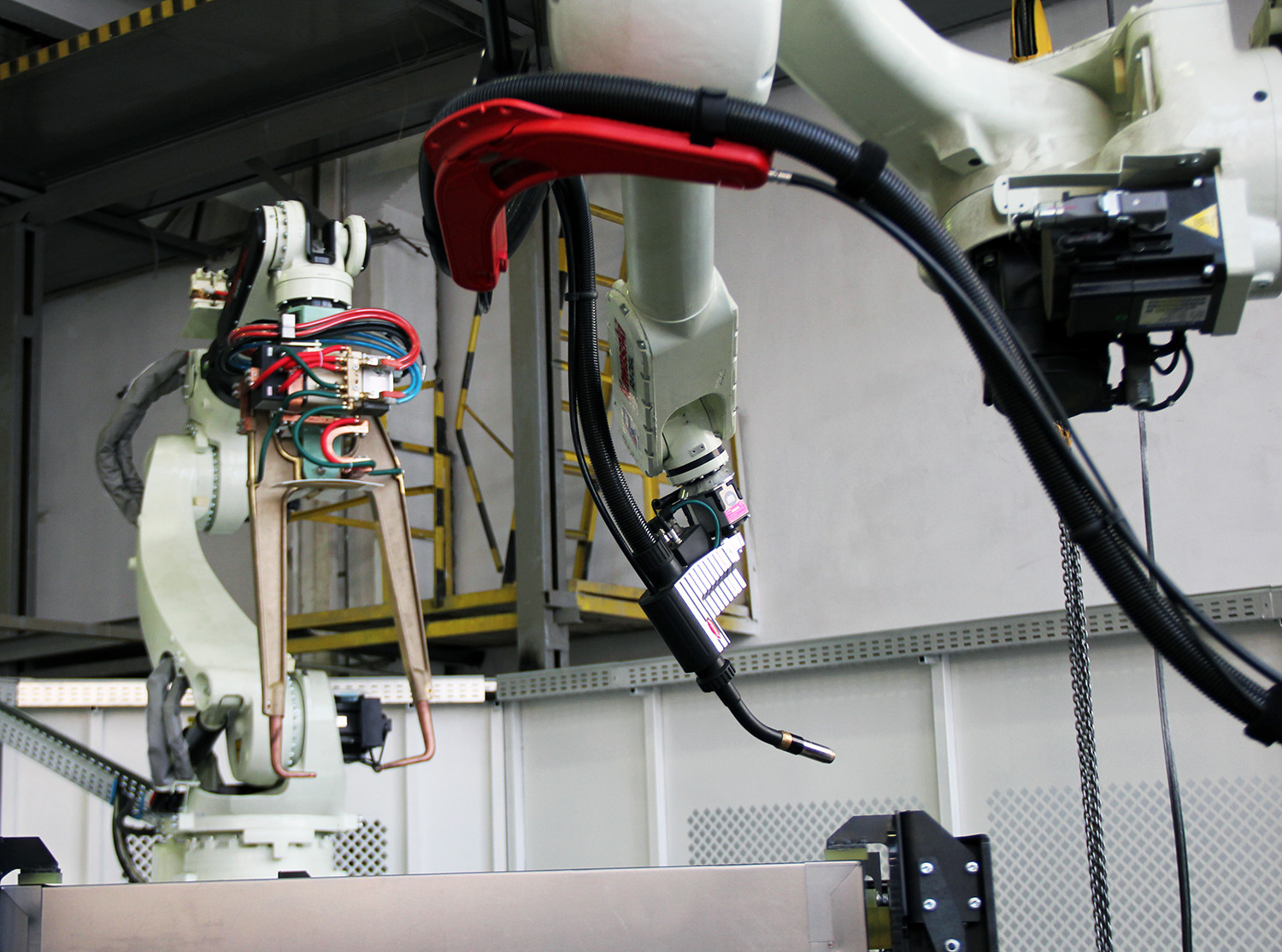

How it was done: when performing this task, spot and arc welding were used. Spot was carried out by the robot Kawasaki BX200L, and arc - RA006L. For this, a multizone robotized cell was built: in the first zone, stiffeners were welded to the walls, and in the second, they were joined together.

BX200L has 6 degrees of freedom, but reach more - 2.5 m. The robot is able to lift up to 200 kg, and the weight of the manipulator is 930 kg.

The technical characteristics of the RA006L are similar to RS006L, the only difference is the availability of special equipment to control the process of arc welding.

Despite the fact that the stiffeners can in principle be joined using the same resistance welding, it was decided to use arc to avoid complicating the shape and increasing the price of the parts themselves.

Unlike welders, who often have high qualification requirements, operators only received instructions on how to work with the RTC. Also, working with a robotic complex is easier and safer than manual welding.

According to representatives of DiKom, after the introduction of the robotic complex, productivity has increased almost 10 times. More about the project

Robots for the construction of the stadium "St. Petersburg"

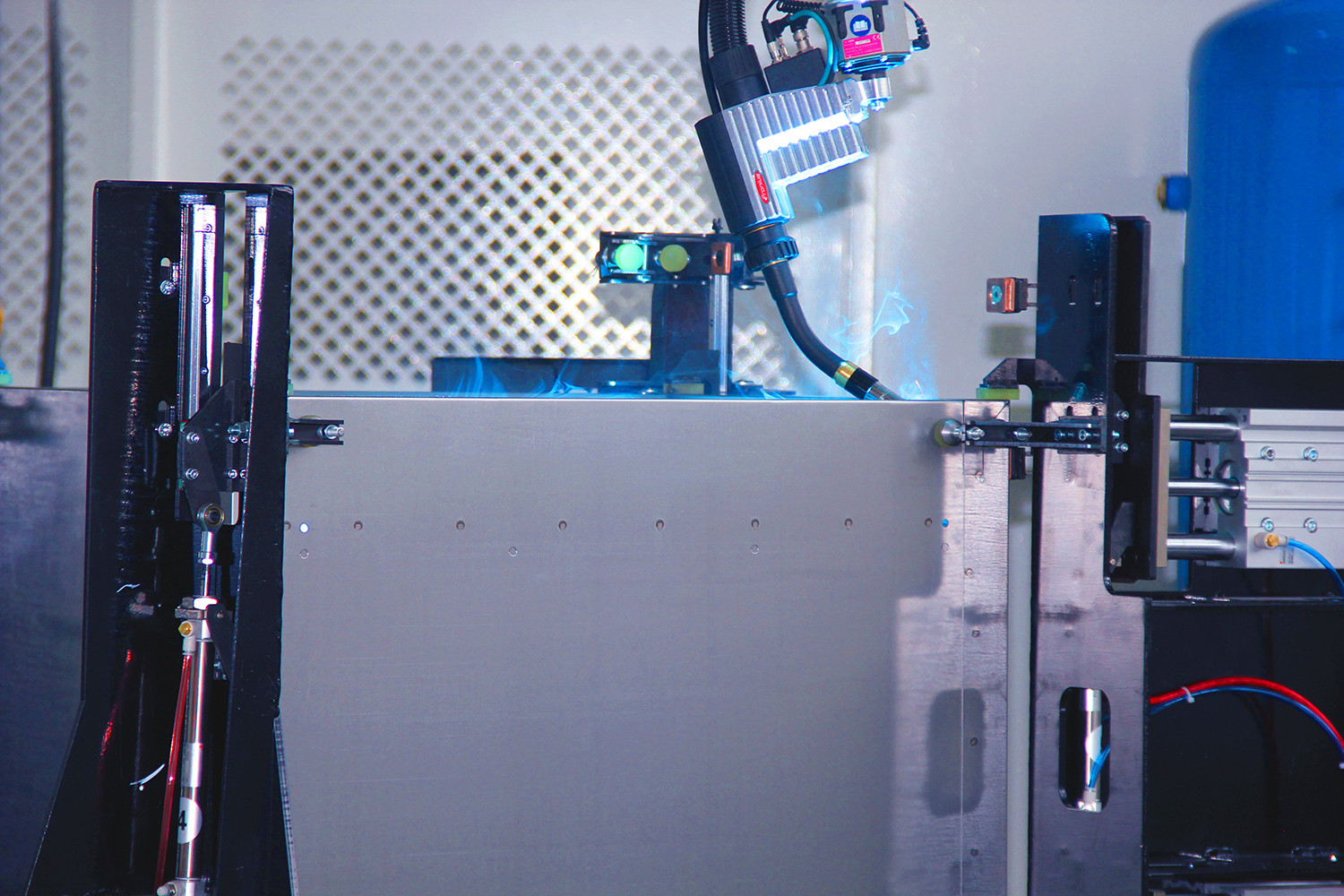

Objective: to make complex spatial 3D-cuts on large diameter pipes.

Contractor: RoboVeld company commissioned by Lenmontazh construction company.

How it was done: in this case, robots were needed in the production of steel structures for the stadium "St. Petersburg".

In Lenmontazh it was considered that it was almost impossible to carry out an order manually - each product had to be unique, which would take too much time and human resources. Therefore, it was decided to introduce plasma cutting into production of RTK.

“Plasma cutting manually differs from the similar one with the use of robots in that the robot can do it more precisely, its hand will not tremble. And most importantly: after robotic cutting, if the whole technology is organized correctly, no further processing may be required. And after the manual, additional cleaning and polishing are necessary, ”explains R. Timofeev.

For work, Roboweld developed an automated system consisting of a Kawasaki RA006L robot, a linear motion module for a robot, a positioner with a clamping chuck, lunettes and the actual plasma cutting equipment.

The software used to control the robot made it possible to create control programs based on the existing virtual 3D-drawings of the pipes. To work with the complex, only one operator per shift was required, and a software engineer who had to create one task for the RTK per shift, thanks to the simplicity of mastering the software, coped with its weekly duties per day. As a result: it took less than 2 months to design, manufacture and implement unique pipes.

More case studies on the use of Kawasaki industrial robots will be reviewed at a conference as part of the Robotics Expo. Roman Timofeev from Robowizard, the official distributor of Kawasaki Robotics in Russia, will tell about them.

All Articles