Paper making paper with Epson PaperLab

The editors of Geektimes have already talked about the announcement of the Epson PaperLab office paper processing machine. Since then, we have received many questions from interested readers, which, finally, we will be able to answer in this post.

Meet Epson PaperLab is the world's first office machine with a closed office paper recycling cycle using a dry process.

Download waste paper - get clean sheets.

Waste paper and what to do with it now

On average, the world produces 400 million tons of paper and cardboard annually. Primary pulp is mainly used for paper production, and recycled waste paper accounts for 38% of the global paper production ( according to the data of the Confederation of European Paper Makers CEPI ).

At the same time processing one ton of printing paper saves more than 2 tons of wood.

So, what happens to the waste paper after its delivery to the processing plant?

Sorting

Raw materials are sorted by quality level. Seven of the twelve types of waste suitable for the manufacture of egg trays, packaging containers, etc. The remaining three types - newspapers, magazines, office paper - are considered the most expensive raw materials. They make notebooks, toilet paper, wallpapers, albums, etc.

The main criterion for classification according to GOST 10700-97 is density and quality. For example, paper for printers and letters belongs to the group "A" - the highest grade.

Dissolution

Compressed paper bales are soaked in special pulper tanks that operate on the principle of a washing machine: the drum creates a twist that mixes and grinds the fibers. Then the waste mass is cleared of impurities: heavy impurities are removed by rotating in the drum: sand, glass, paper clips, etc. they settle in the dirt collector, and the lungs - by passing the mass through a sieve. In the soaking process, chemicals are added, thanks to which the particles of printing ink and ink no longer adhere to the fibers.

The so-called “pulp” obtained at this stage is used for the production of low-grade cardboard, soft fillers, packaging for eggs and further purification and processing.

Next, the pulp is melted by grinding in a mill and subjected to fine cleaning. By the way, the recycling cycle can usually be repeated up to 7 times, with each subsequent processing of the fibers becoming shorter and, ultimately, they become unsuitable for the manufacture of new paper.

What equipment exists for recycling

Of industrial machines and systems there are:

- separate installations for each processing operation;

- combined installations for several operations (mini-plants);

- large factories performing the entire technological chain.

Separate installations for each stage are purchased when the average waste paper flow is expected - 10–50 tons per day. If stable supplies of waste paper occur in much larger volumes, then it is preferable to use a large processing plant.

But mini-plants are in demand in those places where the supply of waste paper does not exceed 3-5 tons per day, because in this case it is pointless to invest in powerful expensive equipment.

Epson PaperLab

More recently - in 2016 - another type of processing machines appeared - the most compact. The whole process of processing and production fits in one unit. Just such a class of devices and applies Epson PaperLab.

The installation has a record compact size for this class of equipment - only 2.6 × 1.2 × 1.8 m.

The main feature of PaperLab is that it is the first in the world (according to Seiko Epson data for November 2016) an office paper processing machine that recycles used paper into a new one using a dry process .

Unlike the traditional recycling system, which uses large amounts of water, PaperLab practically does not use water (apart from the very small amount of water that is required to maintain the moisture level of the system, but the machine does not require connection to the water supply system and can be installed in any office) .

That is, in addition to preserving trees, the new device also saves water.

Epson engineers began working on PaperLab in 2011 and developed the Dry Fiber technology, continued working on it and in 2016 received the prestigious Nikkei Global Environmental Technology award for this technology.

Epson Dry Fiber Technology

In order not to overload the post information, we will tell about the principle of operation of the Dry Fiber technology as short as possible:

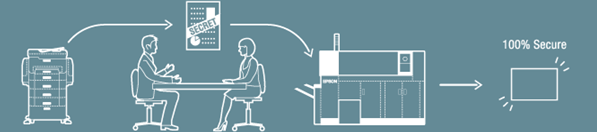

- Loading

Used paper of various form factors is loaded into PaperLab. - Fiber dissolution

An anhydrous defibration unit developed by Epson mechanically breaks the paper into long thin fibers. This process instantly and irrevocably destroys confidential documents. Since PaperLab does not use water for recycling, there is no need to connect the machine to the plumbing system, which means that the machine can be installed in any office. - Splicing, fastening

The fibers are mixed with PaperPlus binders, which give strength and whiteness to the paper. In addition, at the same stage, you can add to the carrier color, aroma and substances that increase the fire resistance of the finished product. - Molding

The fibers are laid out in a thin layer and are formed into a sheet under pressure. At this stage, sets the strength, thickness and dimensions of the sheet. - Crop sheet for the required format

Voila! Brand new sheets are ready for printing!

What are the advantages of PaperLab

In one minute, PaperLab is able to produce about 12 A4 sheets. This is 720 sheets per hour or 5760 sheets per 8-hour working day. The exit time of the first sheet is 3 minutes from the moment the “Start” button is pressed. In addition to this performance, the device has the following advantages:

- Closed loop paper recycling in the office

As a rule, the recycling of paper includes the delivery of waste paper from the office to the plant. PaperLab allows you to speed up this process and make it local - that is, you can recycle paper, as they say, "without departing from the cash register." - Secure destruction of confidential documents

If you work with documents of high secrecy, be sure that confidential documents will never leave the building: PaperLab completely and irreversibly destroys all information from the paper during the recycling process. Moreover, this can be done without leaving the office, and without resorting to the services of third-party organizations. Unlike a shredder, PaperLab eliminates even the theoretical possibility of data recovery due to the fact that the ink or toner is completely separated from the paper fibers and collected in one container with a working out.

- Extensive "customization" of paper

When creating a paper device allows you to set its properties. Can:

- change the color of the paper;

- get the paper of the desired format up to A3;

- create paper of different density (from plain office paper 90 g / m 2 to thick paper for postcards 150-240 g / m 2 ),

- and even flavor paper

- Environmental responsibility - taking care of the future

Recycling directly in the office helps to reduce the negative impact on the environment:

- PaperLab helps reduce CO2 emissions. The point of transportation of products is excluded from the processing chain, moreover, both sending waste paper for processing and ordering new paper. Less cars - less exhaust.

- The need to purchase new paper is reduced, which means that we are saving the planet’s invaluable resource - trees.

- PaperLab produces paper without water (not counting the small amount of water required to maintain a certain level of moisture in the system). As a rule, for the production of a single A4 sheet according to the traditional scheme, approximately a cup of water is required. Therefore, since the machine uses “dry recycling,” PaperLab saves up to 54,500 liters of water per ton of paper created .

I want my own paper mill

Still would. Everyone wants!

But at the moment there is one valid PaperLab sample in the world. He is in Europe and sometimes tours major international exhibitions. Industrial production of PaperLabs is scheduled to begin shortly.

In this publication, we collected all the information shared by our Japanese colleagues. As soon as there is still something interesting, we will definitely tell and make a detailed post-review of the device itself.

We thank you for your attention!

All Articles