Cobalt 60 at home and at work

Among all artificial radioactive isotopes used by mankind, cobalt 60 has found the widest application. This isotope has a combination of high specific activity, high energy of gamma radiation, a convenient half-life and the presence of only one natural stable isotope (which simplifies transmutation). In fact, gamma-radiation sources based on cobalt 60 are a kind of standard option wherever photons with energies greater than 1 MeV are needed. Today I will explain how this isotope is obtained and used.

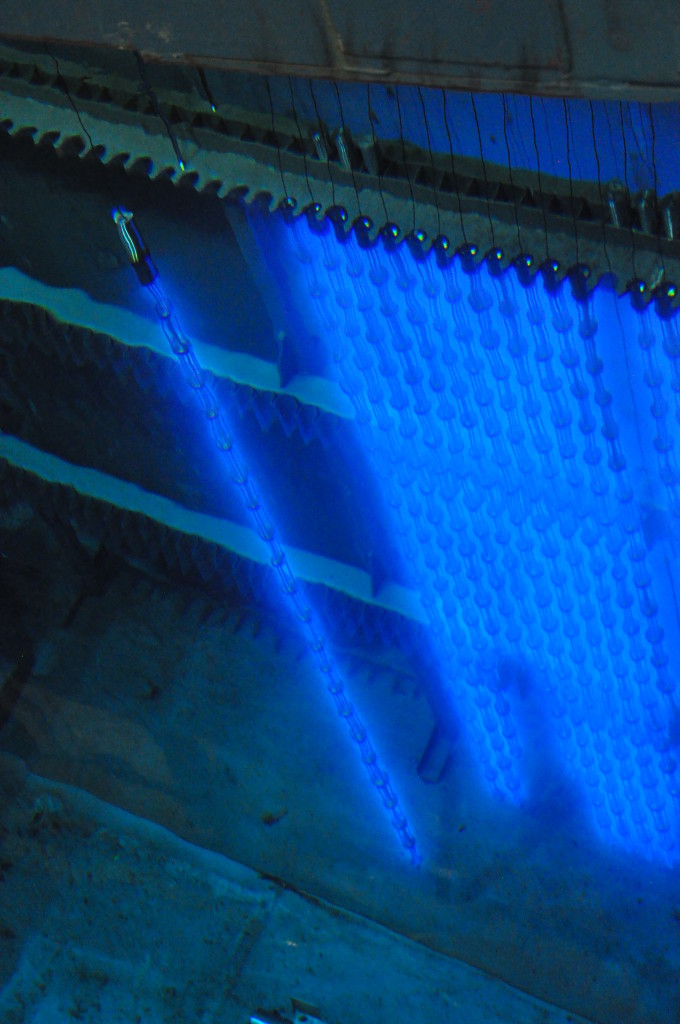

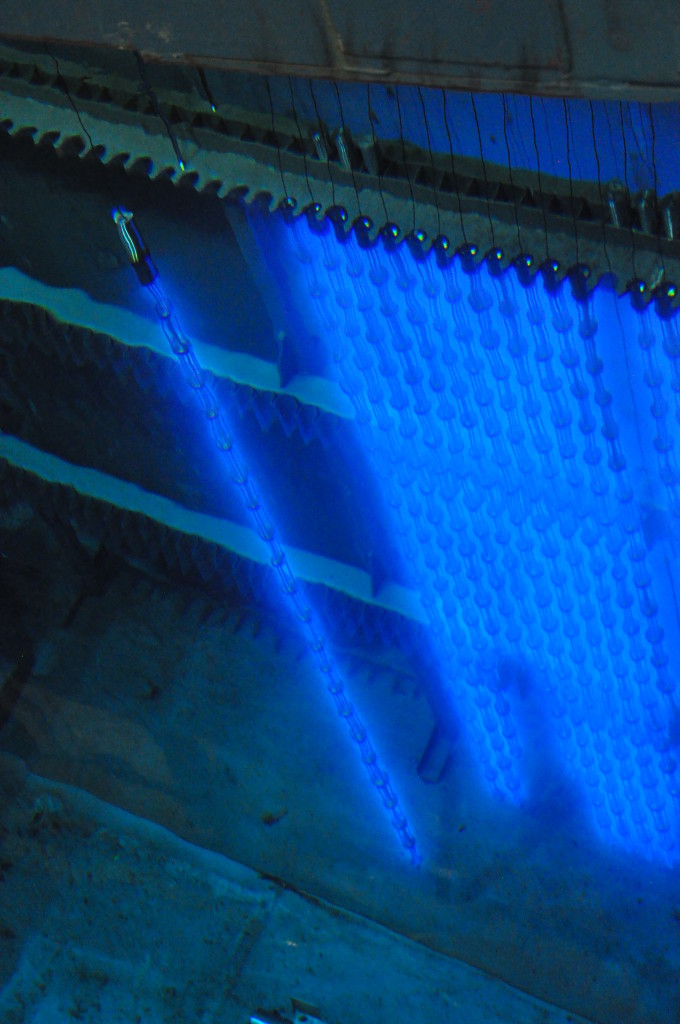

Panoramic cobalt 60 irradiator lowered into the pool for maintenance. Such an irradiator is capable of creating dose rates of up to 2 million X-rays per hour at a distance of 20 cm from the surface.

Cobalt 60 is an activation isotope, i.e. it is obtained as a result of neutron absorption by natural cobalt 59. This process has maximum efficiency (37 barn) on thermal neutrons, therefore, in general, almost any reactor is suitable for production.

The largest 60Co manufacturers in the world are channel reactors - heavy water CANDU (Canadian Bruce NPP, Korean Wolsong and Argentinian Embalse) and water-graphite RBMK installed at Leningrad NPP. The advantage of channel reactors is the ability to unload and load irradiated targets, regardless of the reactor operating cycle.

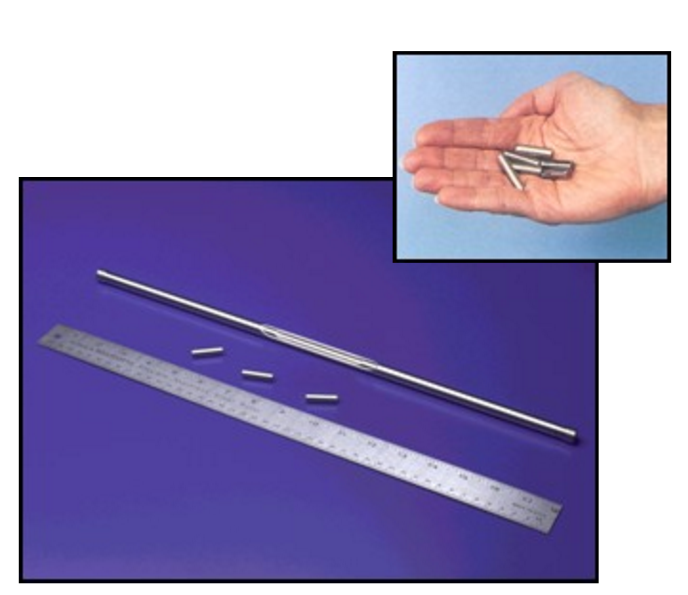

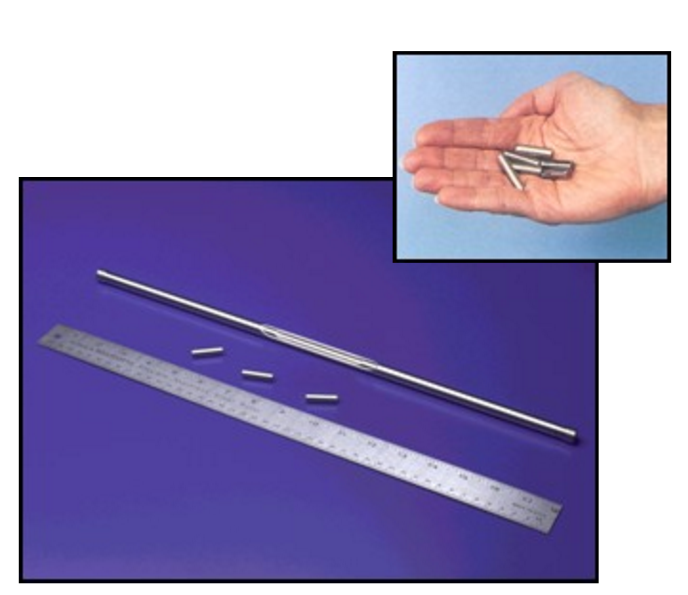

Target for cobalt irradiation in an American ATR reactor.

By the way, one of the last significant changes in the cobalt market was a project for the production of this isotope in blankets of the BN-800 reactor, which provides a large neutron flux and allows you to get a product with high specific activity faster. However, the first product will not appear before 2019.

The process of producing cobalt-60 itself is relatively simple (relative to 238Pu, for example). Various forms of metallic cobalt (shot, wire, cylindrical elements) are placed in a zirconium or stainless steel target, installed in an irradiation device, and lowered into the reactor. After exposure to the desired activity, the targets are removed, opened in the hot chamber. Cobalt-60 is sorted by activity and repacked into sources, after which it is shipped to the customer.

Elements of natural cobalt, double-walled case, device for transporting canisters and a container with 27 cm walls of lead and steel for transportation weighing almost 6 tons.

The total production of cobalt 60 in the world today is about 75 million curies per year, which is divided into two types: cobalt with low and medium activity (up to 100 curie per gram) and highly active cobalt (250+ curie per gram). The latter is considered a high-tech product and is used mainly in medical applications, its release is ~ 2.5 million curies per year. With the cost of one curie of low-level cobalt about $ 2 per curie and highly active about $ 25 per curie, the total market for this isotope is ~ $ 200 million, surpassing the molybdenum market of 99Mo and nuclear-doped silicon. By the way, in terms of cost, it looks like it is the cheapest (or one of the cheapest) radioactive gamma emitter - at least several times cheaper than 137Cs and 90Sr in terms of 1 curie.

Irradiated cobalt targets with high specific activity in the holding pool of Bruce NPP

Why is 60Co so much in demand (and the market is growing at a rate of 4% per year)? Cobalt 60 decays into 60Ni by emitting gamma quanta with an energy of ~ 1.3 MeV, which penetrate deeply into almost any material and at the same time have a high ionizing ability. During sterilization, for example, this allows you to “light up” large volumes of the product at once, and when measuring the thickness of a material, it is possible to measure very thick metal parts that are inaccessible to X-ray installations.

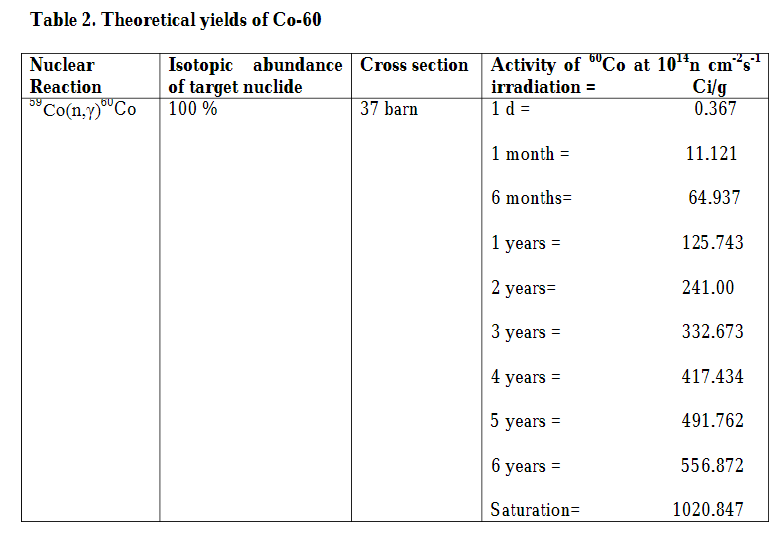

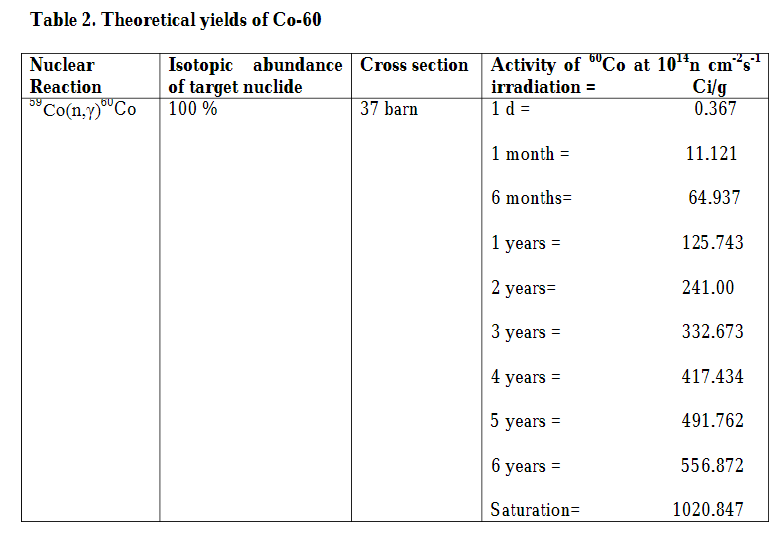

The growth of specific activity of cobalt targets when irradiated in a reactor with a flow of 10 ^ 14 n / cm ^ 2 * c

In addition, cobalt 60 has a rather convenient half-life of 5.27 years. On the one hand, the higher the half-life, the longer the source works, but on the other hand, the harder and more expensive the process of its burial. In the case of 60Co, a typical case for a panoramic feed (about them below), containing at the beginning about 6000-8000 Ci (100 grams of cobalt specific activity 60-80 Ci / g) after 20 years of use has 431-576 Ci and can be released from the category radioactive waste in 120-130 years, i.e. does not require expensive underground burial, but only storage. At the same time, gamma-emitting isotopes with an even shorter half-life, for example, 22Na with a half-life of 2.6 years and 192Ir with a half-life of 78 days are no longer so convenient in terms of replacement frequency and associated logistic volumes (sodium, moreover, is widely used due to chemical activity and swelling of sources from the decay product - neon).

Some more containers for the transportation of cobalt 60. Every year around 1000 transports of similar containers are carried out in the world.

The main competitor of 60Co is the not unknown fragmentation isotope 137Cs. The advantages of cobalt here include:

Where does Cobalt 60 apply?

The main market in which 60Co is used is the sterilization of medical products and a variety of foods, such as spices, seafood and mangoes. Typically, these operations are performed at centralized sterilization stations, where a panoramic feed is installed, containing 2-4 million curies of cobalt 60 and a conveyor transporting the sterilized products around this feed.

Panoramic feeds are collected from such stainless steel canisters with cobalt tablets. The case usually has a double wall and is checked for tightness.

Gamma sterilization has two similar alternatives - x-ray sterilization and electron beam sterilization. Technological difference of the last two types in the use of a small accelerator to create a stream of electrons (and as an option - X-rays from this stream of electrons). The advantage of cobalt sterilization here is a simpler device and the ability to work with large volumes of irradiated material, and the disadvantage is the inability to “turn off” the radiation (although this is solved by immersing irradiators in a pool of water), working with large amounts of radioactive material and lower available doses compared to with electron beam.

Outline of a typical gamma sterilization center. The conveyor with the irradiated products moves around the panoramic feed, the processing chamber is surrounded on all sides by bio-protection, and the panoramic feed can be lowered down into the pool for work with the equipment of the radiation chamber. Cobalt canister replacement is also carried out under water.

For a typical panoramic sterilizer, the exposure time ranges from a few seconds (for example, it takes so much to sterilize insects to suppress their population in nature) to 10 hours for pharmaceutical kits for intravenous infusion or surgical equipment. At the same time in the sterilization chamber on the conveyor can be up to several tons, i.e. The overall performance of this method is quite high.

Video about the work of the gamma sterilization center.

However, despite the shortcomings of sterilization with an electron beam (they can also include the cost of electricity and work only with a layer of 2-3 cm), this method gradually wins the market from cobalt sterilization due to the possibility to put the accelerator in principle at every large hospital and have no problems with logistics.

The IAEA estimates that around 200 large sterilization centers with panoramic feeds operate in the world.

There are several areas where cobalt 60 sources are used in industry. The oldest and most developed are thickness gauges and density meters. As the name implies, the thickness of a material with a known density or density at a known thickness (for example, the ore content in the pulp) is determined by the absorption of gamma radiation from the source to the detector. In the world, tens of thousands of similar devices are used, supplied mainly with sources with 137Cs and 60Co, although isotopes such as 22Na are sometimes used. At the same time, in comparison with panoramic feeds, the content of radioactive isotopes here is small - usually 1 ... 10 curie.

Along with other uses one of the most active is the measurement of the density and moisture of the soil.

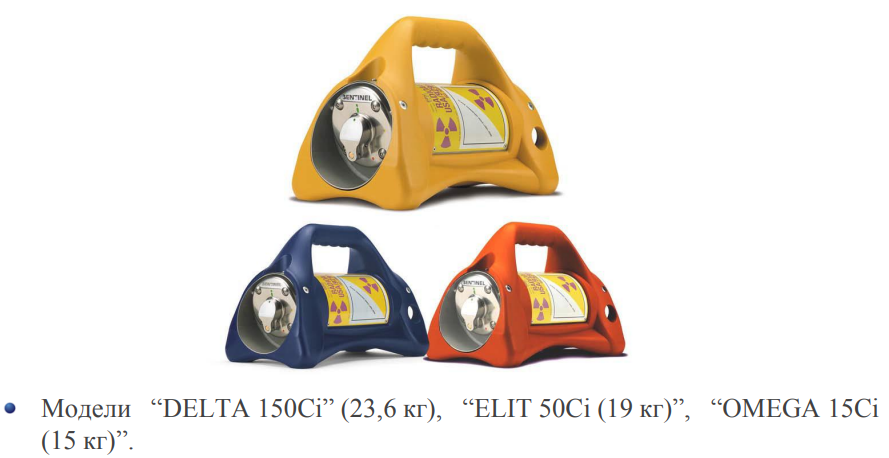

An even more common application of sources with cobalt 60 is gamma flaw detection - mostly thick welds (from 20 to 200 mm). The technology is similar to obtaining x-ray images, only a large thickness of the metal requires the use of radiation with greater energy than the x-ray tube can give. Gamma flaw detectors come in different capacities (calculated for different metal thicknesses) and usually contain from 10 to 400 curie of cobalt 60. Also, the shorter-lived isotopes of selenium 75 and iridium 192 are used.

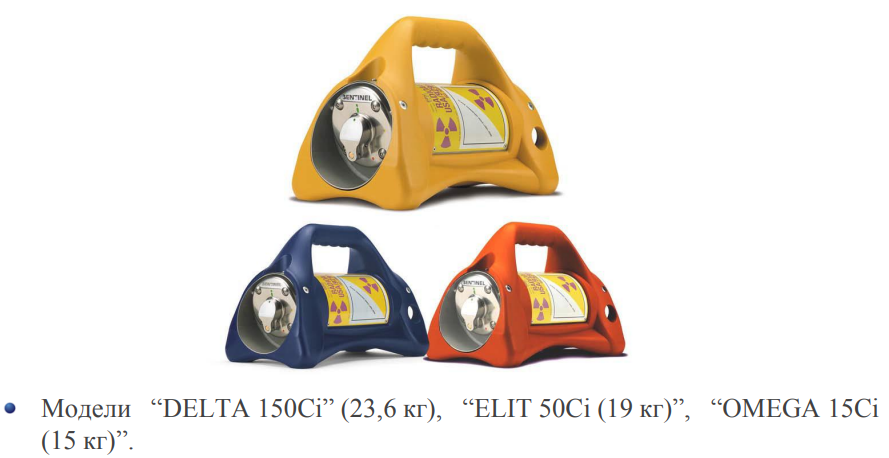

Portable rays of death, also known as gamma flaw detector heads

In addition to the above, sources with cobalt are used (albeit narrow) as altimeters, for example, the landing device of the Soyuz spacecraft is equipped with a similar device that measures the flux of gamma rays reflected from the surface and evaluates the distance to it. This technology is also used to measure the height of bulk substances in tanks, although I did not find any specific examples of production where such a meter would be installed.

Externally, the "Cactus" is not particularly remarkable.

Finally, an important application is the irradiation of plastic polymers to improve their properties. Judging by this pamphlet, all properties of plastics are improved drastically due to the formation of transverse chemical bonds. Basically, the dose set is achieved using beta radiation (i.e., the electron beam from the accelerator), but about 25% of such operations are performed using panoramic emitters, similar to those used in sterilization (moreover, some gamma sterilization centers plastics are irradiated on the same equipment).

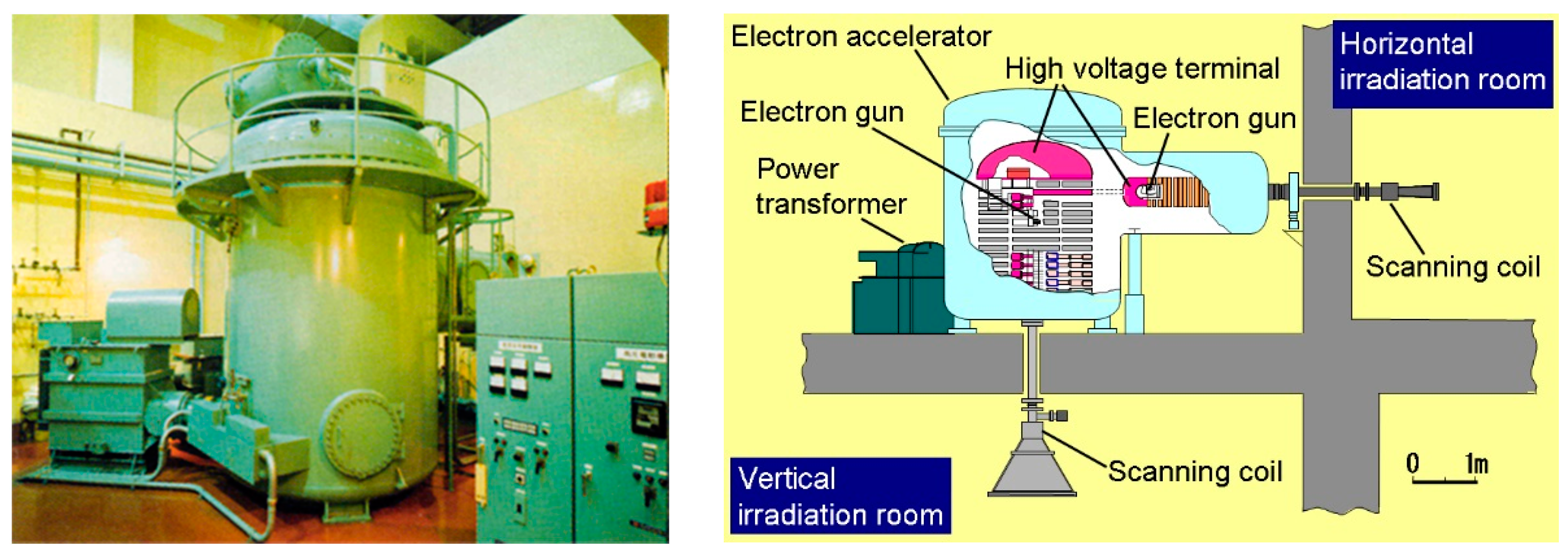

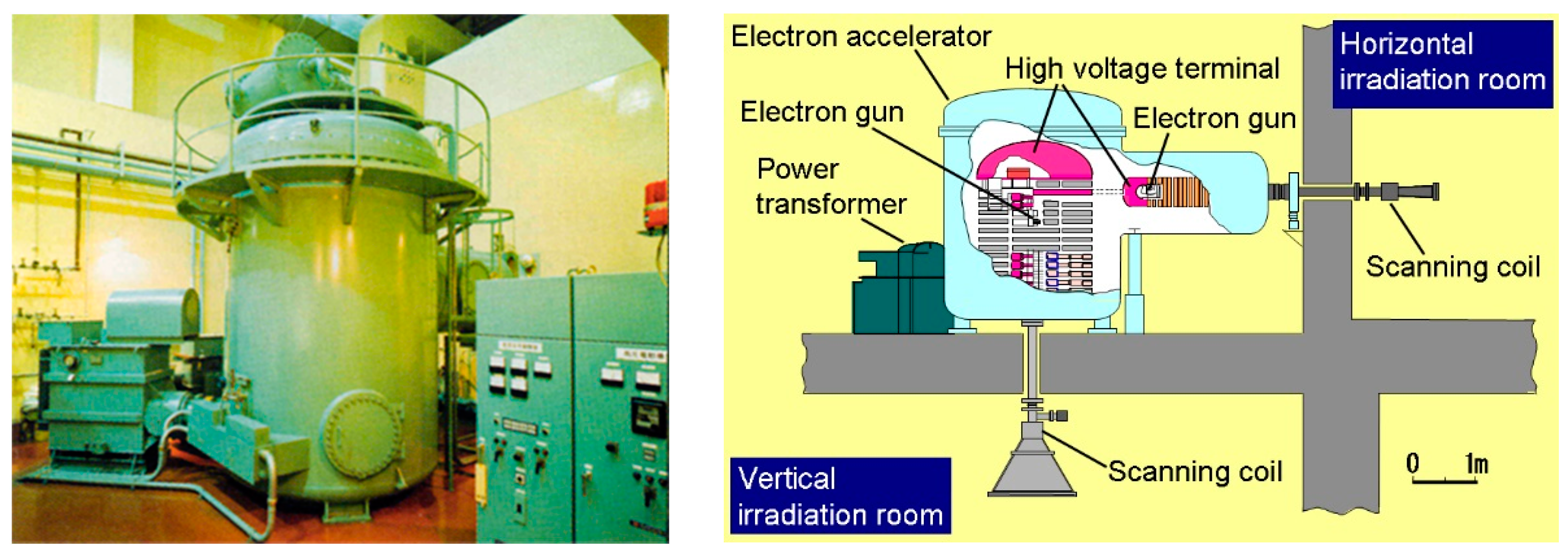

However, mainly plastics are irradiated at such electrostatic electron accelerators with an energy of 0.7-1.5 MeV, due to their extremely high dose productivity.

In the 1960s, collimated gamma-based sources of radiocobalt were the primary means of radiotherapy.

Cobalt 60 is actively used in medicine, mainly in the field of cancer therapy. Although this radioisotope is now practically extruded from standard radiation therapy with accelerator sources of ionizing radiation, it is still widely used in gamma knives and brachytherapy.

The principle of operation and the real gamma knife. In the photo, obviously, mock sources, otherwise the photographer would get a few rem at best.

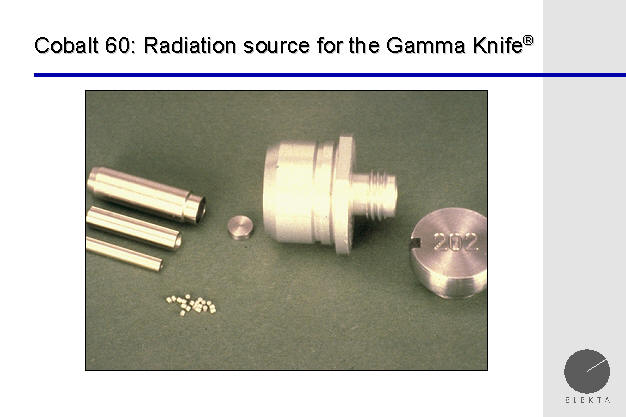

Gamma Knife is a device for radiosurgery of tumors in the brain. Technically, the installation consists of several hundred collimated sources of gamma radiation, covered by an absorbing curtain, located around the patient's head. For therapy, point source beams intersect at the tumor, thereby creating the necessary dose rate in this place. It is for the gamma knife that cobalt-60 with high specific activity is needed. The advantage of 60Co here is the high energy of gamma radiation, weakly absorbed by the tissue and almost monoenergetic radiation, unlike many other medical isotopes.

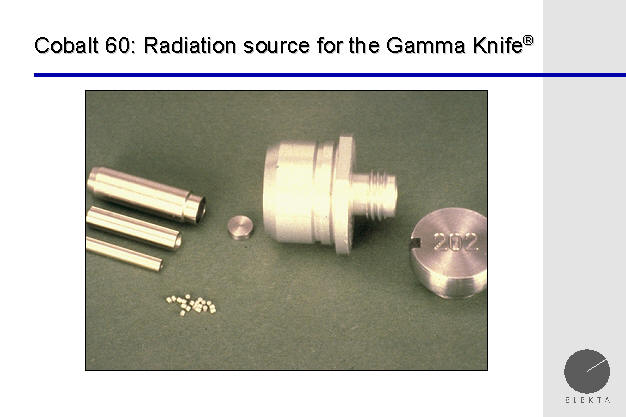

Another image of a gamma knife and the standard source used in it. Cobalt is small pieces of material at the bottom of the source image, the rest is shells and collimator.

The second major use of cobalt in medicine is brachytherapy - the insertion of several capsules with a radioisotope into the tumor for internal irradiation, especially for those cases when a source with high-energy gamma radiation (for example, breast cancer) is needed. Here, 60Co has the advantages of less radiation damage to surrounding organs and the possibility of recruiting large doses.

Radioactive source for cancer brachytherapy, installed in the patient's body.

Cobalt is a convenient isotope for creating powerful gamma-radiation fields, which are mainly used to study changes in the properties of materials and equipment under the influence of gamma radiation. For example, improving the properties of plastics or determining the radiation resistance of microcircuits. About 30 such irradiation facilities work in laboratories around the world.

In addition, cobalt 60 is one of the metrological standards on which all equipment for measuring the power of gamma radiation is calibrated.

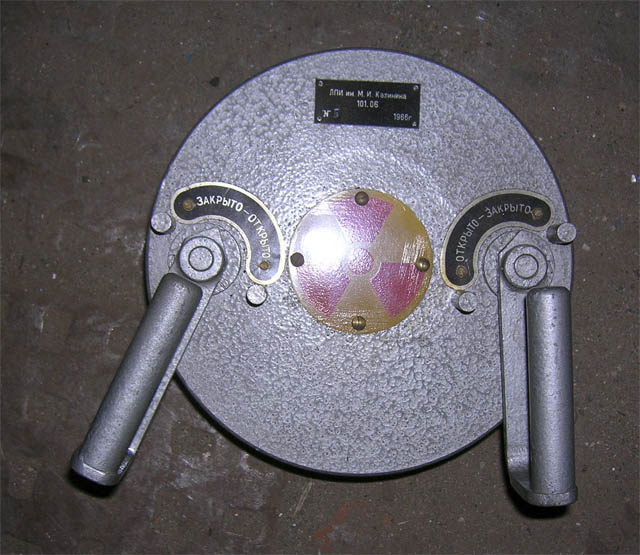

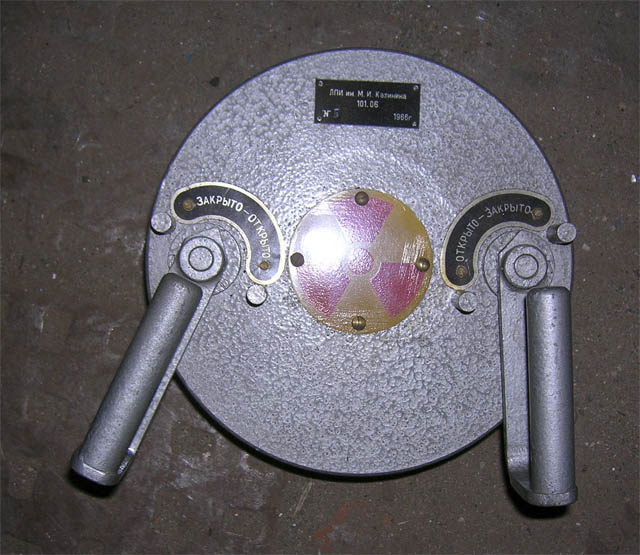

A typical laboratory for calibrating measuring instruments is on the left a source in protection (the electric drive of the shutter is visible), a trolley for moving the instrument with an installed calibration radiometer.

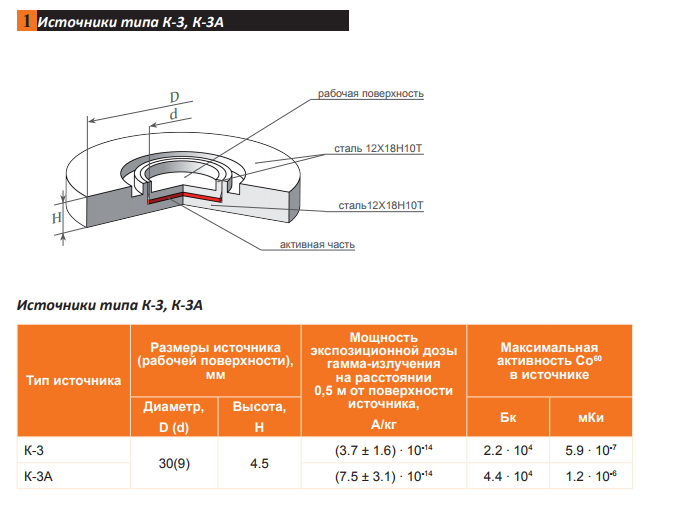

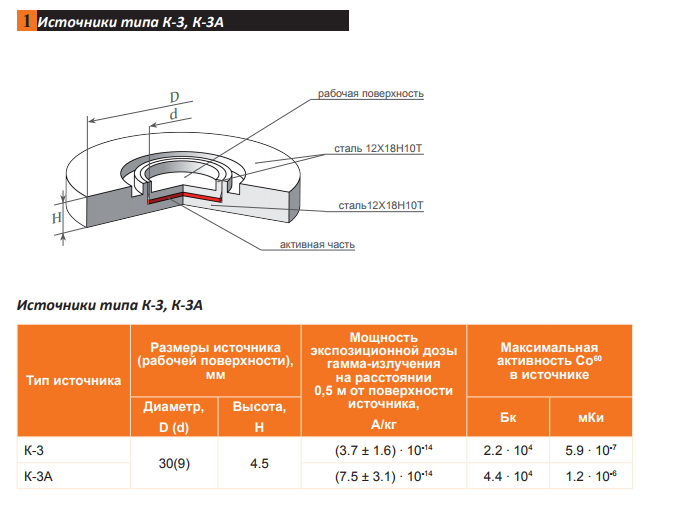

One of the standard sources for which dosimeters and radiometers are tested and calibrated in our country.

But scientists can use other toys, such as the 400 gigawatt pulsed gamma radiation source HERMES-III

Despite the fact that the last decades of 60Co-based ionizing radiation sources are being squeezed out of some niches by accelerating radiation sources, this cheap and convenient isotope remains a widely used source of gamma radiation. For the nuclear industry, in turn, it is one of the most important products that is in demand outside the industry itself. The wider use of cobalt, however, is hampered by the complexity and costly security measures that must be taken when transporting and using radioactive materials.

PS And about the cobalt bomb. This widely publicized idea from the 50s actually has little practical meaning. Firstly, in modern nuclear munitions there is not a large amount of excess neutrons to activate noticeable amounts of cobalt, secondly, this process of activation by fast neutrons is not very effective, thirdly nuclear munitions due to fission stages and so gives large volumes of radionuclides, moreover, different, finally, exponential profiles of precipitations of a nuclear explosion lead to the fact that, even by increasing the number of radionuclides by 2-3 times, we slightly increase the contaminated area.

Panoramic cobalt 60 irradiator lowered into the pool for maintenance. Such an irradiator is capable of creating dose rates of up to 2 million X-rays per hour at a distance of 20 cm from the surface.

Production

Cobalt 60 is an activation isotope, i.e. it is obtained as a result of neutron absorption by natural cobalt 59. This process has maximum efficiency (37 barn) on thermal neutrons, therefore, in general, almost any reactor is suitable for production.

The largest 60Co manufacturers in the world are channel reactors - heavy water CANDU (Canadian Bruce NPP, Korean Wolsong and Argentinian Embalse) and water-graphite RBMK installed at Leningrad NPP. The advantage of channel reactors is the ability to unload and load irradiated targets, regardless of the reactor operating cycle.

Target for cobalt irradiation in an American ATR reactor.

By the way, one of the last significant changes in the cobalt market was a project for the production of this isotope in blankets of the BN-800 reactor, which provides a large neutron flux and allows you to get a product with high specific activity faster. However, the first product will not appear before 2019.

The process of producing cobalt-60 itself is relatively simple (relative to 238Pu, for example). Various forms of metallic cobalt (shot, wire, cylindrical elements) are placed in a zirconium or stainless steel target, installed in an irradiation device, and lowered into the reactor. After exposure to the desired activity, the targets are removed, opened in the hot chamber. Cobalt-60 is sorted by activity and repacked into sources, after which it is shipped to the customer.

Elements of natural cobalt, double-walled case, device for transporting canisters and a container with 27 cm walls of lead and steel for transportation weighing almost 6 tons.

The total production of cobalt 60 in the world today is about 75 million curies per year, which is divided into two types: cobalt with low and medium activity (up to 100 curie per gram) and highly active cobalt (250+ curie per gram). The latter is considered a high-tech product and is used mainly in medical applications, its release is ~ 2.5 million curies per year. With the cost of one curie of low-level cobalt about $ 2 per curie and highly active about $ 25 per curie, the total market for this isotope is ~ $ 200 million, surpassing the molybdenum market of 99Mo and nuclear-doped silicon. By the way, in terms of cost, it looks like it is the cheapest (or one of the cheapest) radioactive gamma emitter - at least several times cheaper than 137Cs and 90Sr in terms of 1 curie.

Irradiated cobalt targets with high specific activity in the holding pool of Bruce NPP

Why is 60Co so much in demand (and the market is growing at a rate of 4% per year)? Cobalt 60 decays into 60Ni by emitting gamma quanta with an energy of ~ 1.3 MeV, which penetrate deeply into almost any material and at the same time have a high ionizing ability. During sterilization, for example, this allows you to “light up” large volumes of the product at once, and when measuring the thickness of a material, it is possible to measure very thick metal parts that are inaccessible to X-ray installations.

The growth of specific activity of cobalt targets when irradiated in a reactor with a flow of 10 ^ 14 n / cm ^ 2 * c

In addition, cobalt 60 has a rather convenient half-life of 5.27 years. On the one hand, the higher the half-life, the longer the source works, but on the other hand, the harder and more expensive the process of its burial. In the case of 60Co, a typical case for a panoramic feed (about them below), containing at the beginning about 6000-8000 Ci (100 grams of cobalt specific activity 60-80 Ci / g) after 20 years of use has 431-576 Ci and can be released from the category radioactive waste in 120-130 years, i.e. does not require expensive underground burial, but only storage. At the same time, gamma-emitting isotopes with an even shorter half-life, for example, 22Na with a half-life of 2.6 years and 192Ir with a half-life of 78 days are no longer so convenient in terms of replacement frequency and associated logistic volumes (sodium, moreover, is widely used due to chemical activity and swelling of sources from the decay product - neon).

Some more containers for the transportation of cobalt 60. Every year around 1000 transports of similar containers are carried out in the world.

The main competitor of 60Co is the not unknown fragmentation isotope 137Cs. The advantages of cobalt here include:

- A simpler production process that does not require radiochemistry

- Twice the big energy of gamma radiation

- Cesium is an extremely chemical active and volatile element.

- The release of cesium 137 from the category of radioactive waste will take hundreds of years.

Where does Cobalt 60 apply?

Sterilization

The main market in which 60Co is used is the sterilization of medical products and a variety of foods, such as spices, seafood and mangoes. Typically, these operations are performed at centralized sterilization stations, where a panoramic feed is installed, containing 2-4 million curies of cobalt 60 and a conveyor transporting the sterilized products around this feed.

Panoramic feeds are collected from such stainless steel canisters with cobalt tablets. The case usually has a double wall and is checked for tightness.

Gamma sterilization has two similar alternatives - x-ray sterilization and electron beam sterilization. Technological difference of the last two types in the use of a small accelerator to create a stream of electrons (and as an option - X-rays from this stream of electrons). The advantage of cobalt sterilization here is a simpler device and the ability to work with large volumes of irradiated material, and the disadvantage is the inability to “turn off” the radiation (although this is solved by immersing irradiators in a pool of water), working with large amounts of radioactive material and lower available doses compared to with electron beam.

Outline of a typical gamma sterilization center. The conveyor with the irradiated products moves around the panoramic feed, the processing chamber is surrounded on all sides by bio-protection, and the panoramic feed can be lowered down into the pool for work with the equipment of the radiation chamber. Cobalt canister replacement is also carried out under water.

For a typical panoramic sterilizer, the exposure time ranges from a few seconds (for example, it takes so much to sterilize insects to suppress their population in nature) to 10 hours for pharmaceutical kits for intravenous infusion or surgical equipment. At the same time in the sterilization chamber on the conveyor can be up to several tons, i.e. The overall performance of this method is quite high.

Video about the work of the gamma sterilization center.

However, despite the shortcomings of sterilization with an electron beam (they can also include the cost of electricity and work only with a layer of 2-3 cm), this method gradually wins the market from cobalt sterilization due to the possibility to put the accelerator in principle at every large hospital and have no problems with logistics.

The IAEA estimates that around 200 large sterilization centers with panoramic feeds operate in the world.

Industrial application

There are several areas where cobalt 60 sources are used in industry. The oldest and most developed are thickness gauges and density meters. As the name implies, the thickness of a material with a known density or density at a known thickness (for example, the ore content in the pulp) is determined by the absorption of gamma radiation from the source to the detector. In the world, tens of thousands of similar devices are used, supplied mainly with sources with 137Cs and 60Co, although isotopes such as 22Na are sometimes used. At the same time, in comparison with panoramic feeds, the content of radioactive isotopes here is small - usually 1 ... 10 curie.

Along with other uses one of the most active is the measurement of the density and moisture of the soil.

An even more common application of sources with cobalt 60 is gamma flaw detection - mostly thick welds (from 20 to 200 mm). The technology is similar to obtaining x-ray images, only a large thickness of the metal requires the use of radiation with greater energy than the x-ray tube can give. Gamma flaw detectors come in different capacities (calculated for different metal thicknesses) and usually contain from 10 to 400 curie of cobalt 60. Also, the shorter-lived isotopes of selenium 75 and iridium 192 are used.

Portable rays of death, also known as gamma flaw detector heads

In addition to the above, sources with cobalt are used (albeit narrow) as altimeters, for example, the landing device of the Soyuz spacecraft is equipped with a similar device that measures the flux of gamma rays reflected from the surface and evaluates the distance to it. This technology is also used to measure the height of bulk substances in tanks, although I did not find any specific examples of production where such a meter would be installed.

Externally, the "Cactus" is not particularly remarkable.

Finally, an important application is the irradiation of plastic polymers to improve their properties. Judging by this pamphlet, all properties of plastics are improved drastically due to the formation of transverse chemical bonds. Basically, the dose set is achieved using beta radiation (i.e., the electron beam from the accelerator), but about 25% of such operations are performed using panoramic emitters, similar to those used in sterilization (moreover, some gamma sterilization centers plastics are irradiated on the same equipment).

However, mainly plastics are irradiated at such electrostatic electron accelerators with an energy of 0.7-1.5 MeV, due to their extremely high dose productivity.

The medicine

In the 1960s, collimated gamma-based sources of radiocobalt were the primary means of radiotherapy.

Cobalt 60 is actively used in medicine, mainly in the field of cancer therapy. Although this radioisotope is now practically extruded from standard radiation therapy with accelerator sources of ionizing radiation, it is still widely used in gamma knives and brachytherapy.

The principle of operation and the real gamma knife. In the photo, obviously, mock sources, otherwise the photographer would get a few rem at best.

Gamma Knife is a device for radiosurgery of tumors in the brain. Technically, the installation consists of several hundred collimated sources of gamma radiation, covered by an absorbing curtain, located around the patient's head. For therapy, point source beams intersect at the tumor, thereby creating the necessary dose rate in this place. It is for the gamma knife that cobalt-60 with high specific activity is needed. The advantage of 60Co here is the high energy of gamma radiation, weakly absorbed by the tissue and almost monoenergetic radiation, unlike many other medical isotopes.

Another image of a gamma knife and the standard source used in it. Cobalt is small pieces of material at the bottom of the source image, the rest is shells and collimator.

The second major use of cobalt in medicine is brachytherapy - the insertion of several capsules with a radioisotope into the tumor for internal irradiation, especially for those cases when a source with high-energy gamma radiation (for example, breast cancer) is needed. Here, 60Co has the advantages of less radiation damage to surrounding organs and the possibility of recruiting large doses.

Radioactive source for cancer brachytherapy, installed in the patient's body.

The science

Cobalt is a convenient isotope for creating powerful gamma-radiation fields, which are mainly used to study changes in the properties of materials and equipment under the influence of gamma radiation. For example, improving the properties of plastics or determining the radiation resistance of microcircuits. About 30 such irradiation facilities work in laboratories around the world.

In addition, cobalt 60 is one of the metrological standards on which all equipment for measuring the power of gamma radiation is calibrated.

A typical laboratory for calibrating measuring instruments is on the left a source in protection (the electric drive of the shutter is visible), a trolley for moving the instrument with an installed calibration radiometer.

One of the standard sources for which dosimeters and radiometers are tested and calibrated in our country.

But scientists can use other toys, such as the 400 gigawatt pulsed gamma radiation source HERMES-III

findings

Despite the fact that the last decades of 60Co-based ionizing radiation sources are being squeezed out of some niches by accelerating radiation sources, this cheap and convenient isotope remains a widely used source of gamma radiation. For the nuclear industry, in turn, it is one of the most important products that is in demand outside the industry itself. The wider use of cobalt, however, is hampered by the complexity and costly security measures that must be taken when transporting and using radioactive materials.

PS And about the cobalt bomb. This widely publicized idea from the 50s actually has little practical meaning. Firstly, in modern nuclear munitions there is not a large amount of excess neutrons to activate noticeable amounts of cobalt, secondly, this process of activation by fast neutrons is not very effective, thirdly nuclear munitions due to fission stages and so gives large volumes of radionuclides, moreover, different, finally, exponential profiles of precipitations of a nuclear explosion lead to the fact that, even by increasing the number of radionuclides by 2-3 times, we slightly increase the contaminated area.

All Articles