Twisted carbon nanotubes give out up to 250 W per kilogram

Obtaining electricity by mechanical means is a very important task, since there are many things in the surrounding world that are in constant motion: from sea waves to clothing on the human body. The importance of the task attracts a huge number of researchers to this area. As a result, there are now several ways to collect mechanical energy, but many of them have certain drawbacks.

For example, electromagnetic energy generators suffer from low power density and high watt cost if scaled to millimeter size. Piezoelectric and ferroelectric harvesters are well suited for high-frequency small deformations, especially at resonating ultrahigh frequencies, but they lack the elasticity to collect energy from large deformations. There are still promising triboelectric harvesters, as well as methods for collecting the generation of electricity from the interaction of current fluids, a lot of electrochemical methods, including energy collection from deformation of lithium batteries and ionic polymer-metal composite harvesters.

Rubber-based dielectrics are best suited for energy recovery from large mechanical stretch. A thin sheet of elastomer is placed in a sandwich between two deformable electrodes. A voltage is applied to charge a highly elastic capacitor ( ) about 1000 V, as a result of which the capacitor receives a charge . When stretched, the rubber dielectric becomes thinner, while its capacitance resistance increases ( ), due to which there is a change in the potential difference . So is the generation of energy.

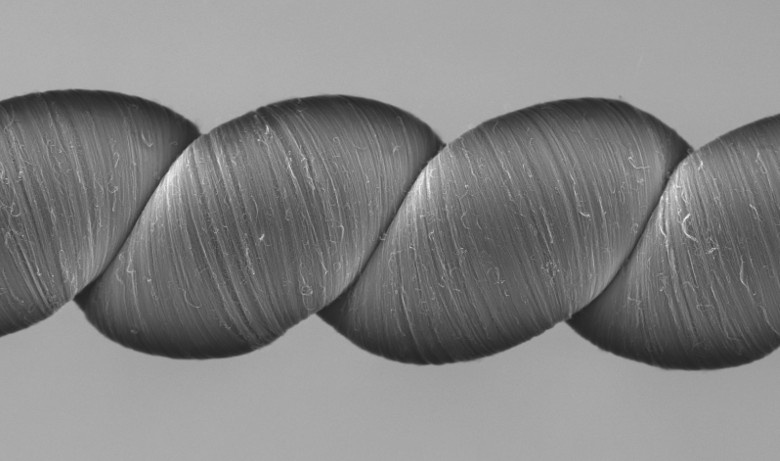

A large international team of scientists from the University of Texas at Dallas, Hanyan University (Seoul) and other educational institutions and research centers were able to improve this type of flexible dielectrics using twisted nanotubes . With their help, we managed to reduce the large voltage that had previously been used to charge the elastomer.

Scientists have demonstrated twisted nanotubes, which give up to 250 W per kilogram without the need for external power supply with a peak efficiency of 30 Hz, as well as up to 41.2 joules per kilogram per mechanical cycle, if normalized to the weight of nanotubes.

According to scientists, such a high output power is due to an extremely dense twist of nanotubes. As the spin density increases, they actually turn into a winding — and the efficiency characteristics drastically improve.

Figure 1A below shows the different methods for twisting the nanotubes, but in reality, conical twisting was used (the first one on the left). The diameter of the harvester is from 50 to 70 microns.

Figure 1F shows that unwinding the nanotube by 8.5% (ie, 500 revolutions per meter) does not lead to the loss of the winding effect, but only leads to an increase in the diameter of the winding and reduces the tightness caused by the twisting. But at the same time, the reversible elongation range (tensile strain range) increases from 30% to 50%, and the resistance-dependent change in resistance increases from 30% to 36%.

According to scientists, such harvesters can be used in different areas:

- collection of sea wave energy

- conversion of heat energy into electricity (along with heat-driven artificial muscles)

- Nanotubes can be embedded in fabric and used to power the LED and to recharge the built-in capacitor

It is important to note that this is not a purely theoretical study. Scientists really collected the current generator of energy from sea waves on swirling nanotubes and tested it in the Sea of Japan. At a water temperature of 13 ° C, the frequency of the waves from 0.9 Hz to 1.2 Hz, the generator between the balloon and the sinker was limited to a maximum stretch of 25%. A ten-centimeter module with twisted nanotubes weighing 1.08 mg showed a peak voltage of 46 mV and an average output power of 1.79 µW. As shown in Figure 4B, with more harvesters, the voltage can increase to any value.

“If our twistronic harvesters can be made cheaper, they can collect huge amounts of energy from the waves of the sea,” said Dr. Ray Baugman, director of the NanoTech Institute and one of the authors of the scientific work. - However, at the moment they are best suited for powering sensors and sensory communications. A harvester on twisted carbon nanotubes weighing only 31 mg can provide the energy needed to transfer 2-kilobyte data packets to a distance of up to 100 meters every 10 seconds on the Internet of Things. ”

The scientific article was published on August 25, 2017 in the journal Science (doi: 10.1126 / science.aam8771, pdf ). It describes the process of manufacturing twisted nanotubes. Among the 29 authors of the article are Yulia Bykova from the Center for Nanoscience and Technologies Lintec of America in Richardson (Texas), which is also nice, after all, the Russian education system still gives some result.

All Articles