Polish HBot

We live during the next scientific and technological revolution. Additive technologies are beginning to penetrate our lives. And as with any change in the technological structure, new equipment manufacturers appear on the scene. They appear, including in those countries that were not previously among the leaders of technical progress. One of such countries is Poland, in which manufacturers of world-class 3D printers appear. One of them, for example, Zortrax, which gained fame several years ago.

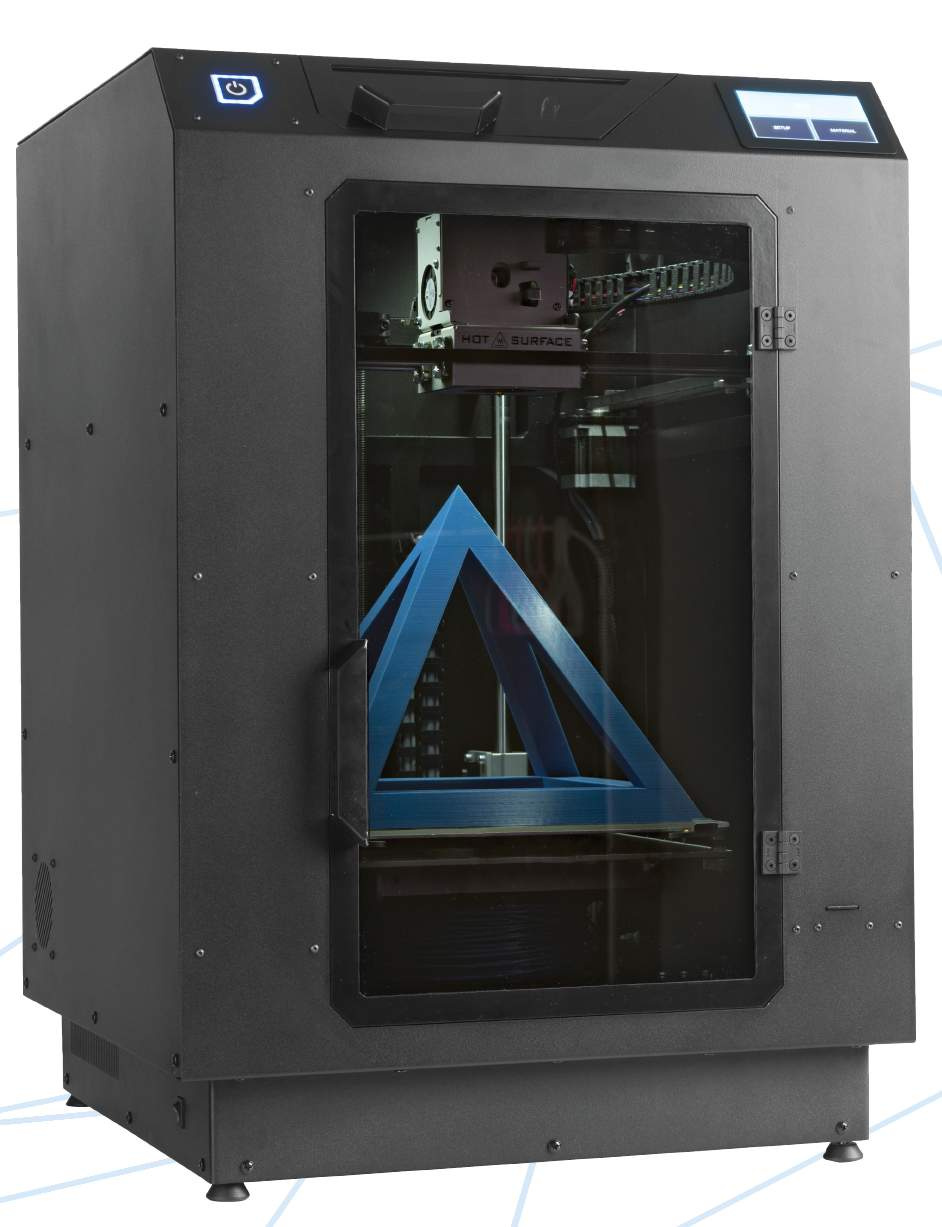

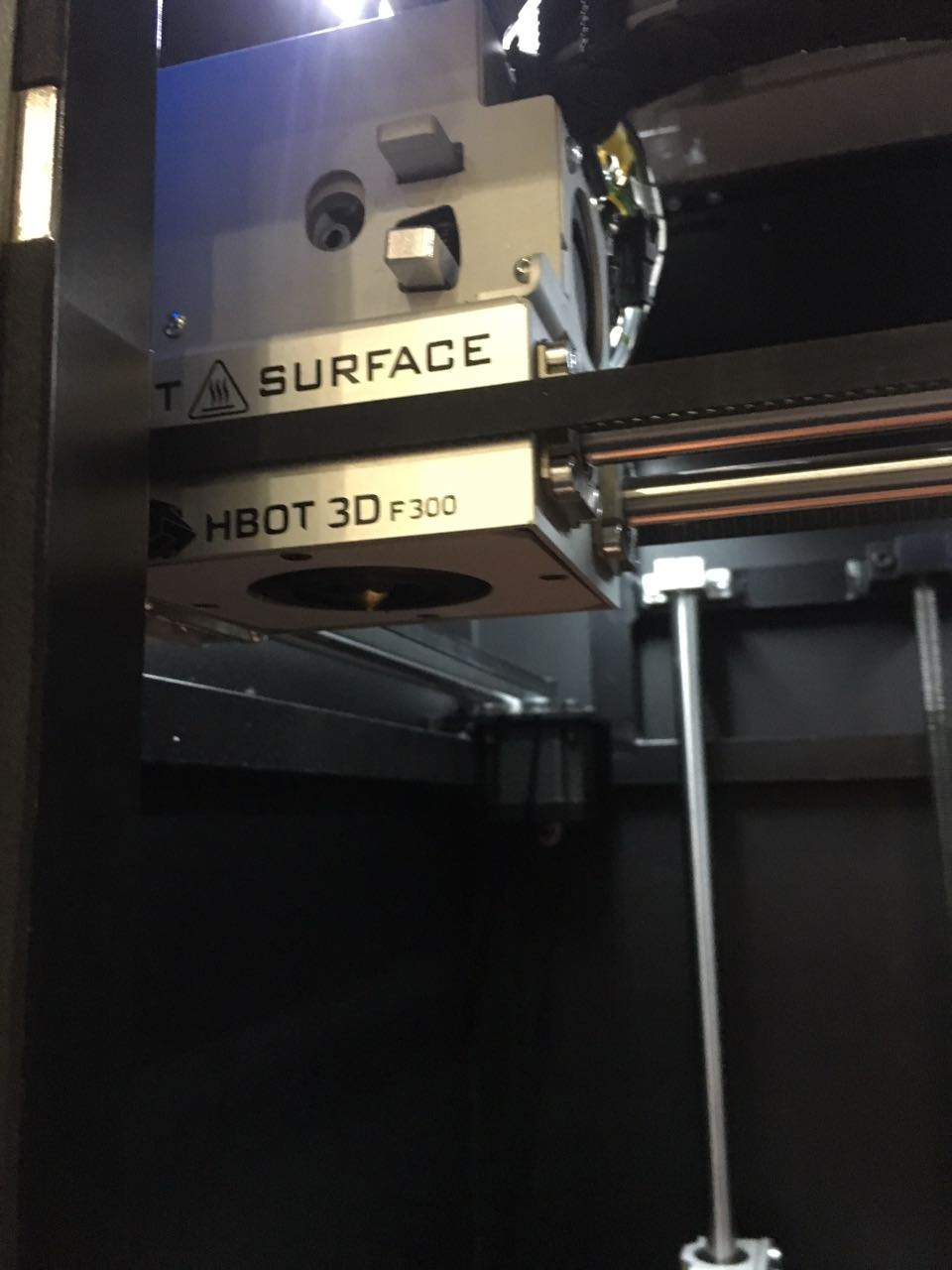

And now goes on the world stage, the manufacturer HBot from the Polish city of Wroclaw. He announced himself, in-house, professional HBot 3D F300 3D printer.

For the first time in Russia, this 3D printer was demonstrated at the recently held Moscow exhibition ROSMOULD 2017.

We visited this exhibition and talked with representatives of the manufacturer, as well as carefully studied the HBOT 3D F300 3D printer. And in this article we want to share with readers our impressions about this very interesting car.

The printer is primarily focused on professional use. We would even say on the production. What is interesting about this printer?

HBot has a large print area of 300x300x300mm. This allows him to create fairly large products. The closed case and the heated table, allow to print plastic with high shrinkage (ABS).

The printer is built on an aluminum frame, on which metal walls are hung. The design on the frame is quite tough, which immediately leads to the conclusion that such decisions will clearly contribute to good accuracy and speed of printing. In a design of the printer metal details are used as much as possible. From which we can conclude that the printer is focused on intensive operation, and not at home use.

The printer is equipped with two transparent doors to access the workspace. Why two? Firstly, in order not to make one huge door with which it will not be very convenient to work. And secondly, thanks to this design, a rigid frame is formed, which will ensure print quality. This is clearly seen in the photo above, where there are two openings, it is just separated by one of the edges of the frame.

The design of the printer is quite minimalistic. On the front surface there is only the power button, and the touch screen control and at the bottom a place for installing an SD card.

All kinematics is based on the h-bot scheme. This is what the printer name tells us. In the photo you can see the lack of printed parts in the design. Only metal, only hardcore. Estimate the thickness of the frame, which can be seen on the back of the printer

The creators of the printer did not hesitate to use thick hardened shafts in the design. This will clearly benefit the print quality of the printer.

Along the Z axis, guides with a diameter of 16mm are used. This avoids any hints of wobbling and greatly adds points in print quality.

In the course of communication, we found out that all components are of European production. Stepper motors such as the production of the Czech Republic, which has always been famous for the high quality of its products. ŠKODA, Česká Zbrojovka, Tatra, Aero Vodochody - the whole world knows the name of these engineering companies.

Build quality can be estimated by the photo.

A 12mm shaft is used along the XY axes, which is also a rather serious decision.

As we understood, the design uses 8 mm wide belts, and not like most 6 mm 3D printers.

Looking at this massive structure, you may get the impression that you cannot achieve high speed here. We all know what measures are used to facilitate the carriage, extruder in other printers.

But here the manufacturer claims a print speed of up to 150 mm / sec. How can this be achieved? And look at the components: powerful stepper motors, wide belts and precision linear bearings, red-hot shafts. All this contributes to high speed and print quality.

The printer uses a direct extruder with a non-standard solution for plastic 2.85 mm. Yes Yes exactly. Apparently the manufacturer has serious arguments for such a decision.

The extruder is optimized for printing with various flexible materials. This is for him no difficulty. It can heat up to 270 ° C, which makes it possible to print the vast majority of plastics on the market.

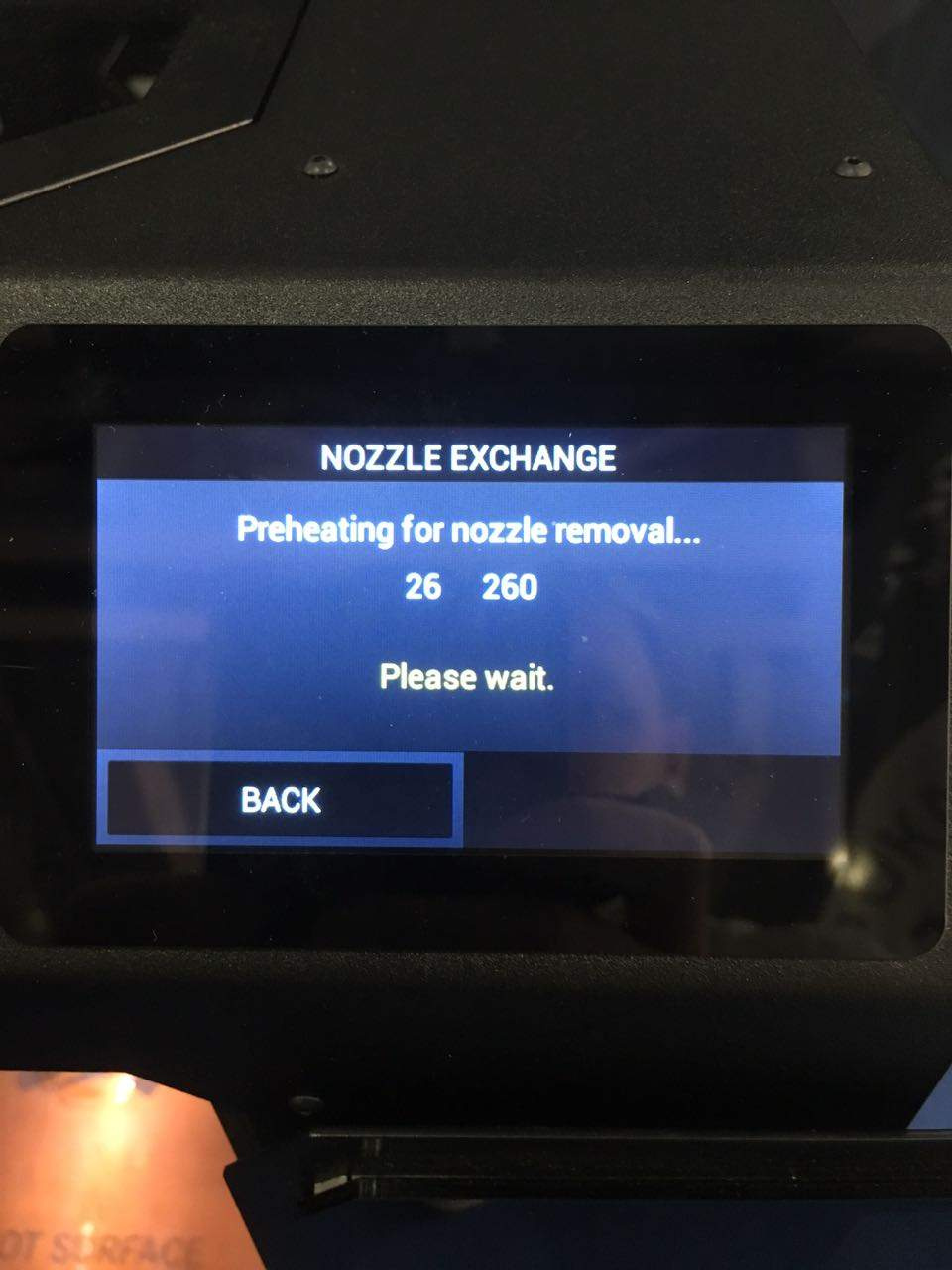

Extruder nozzle removable. Nozzles with different diameters up to 1 mm can be installed. Given the size of the print camera 300x300x300mm, this is a very useful factor when printing large models. What is the use? When printing large products, printing time becomes critical. In order to reduce printing time, you can use nozzles of larger diameter. This feature is implemented in this printer.

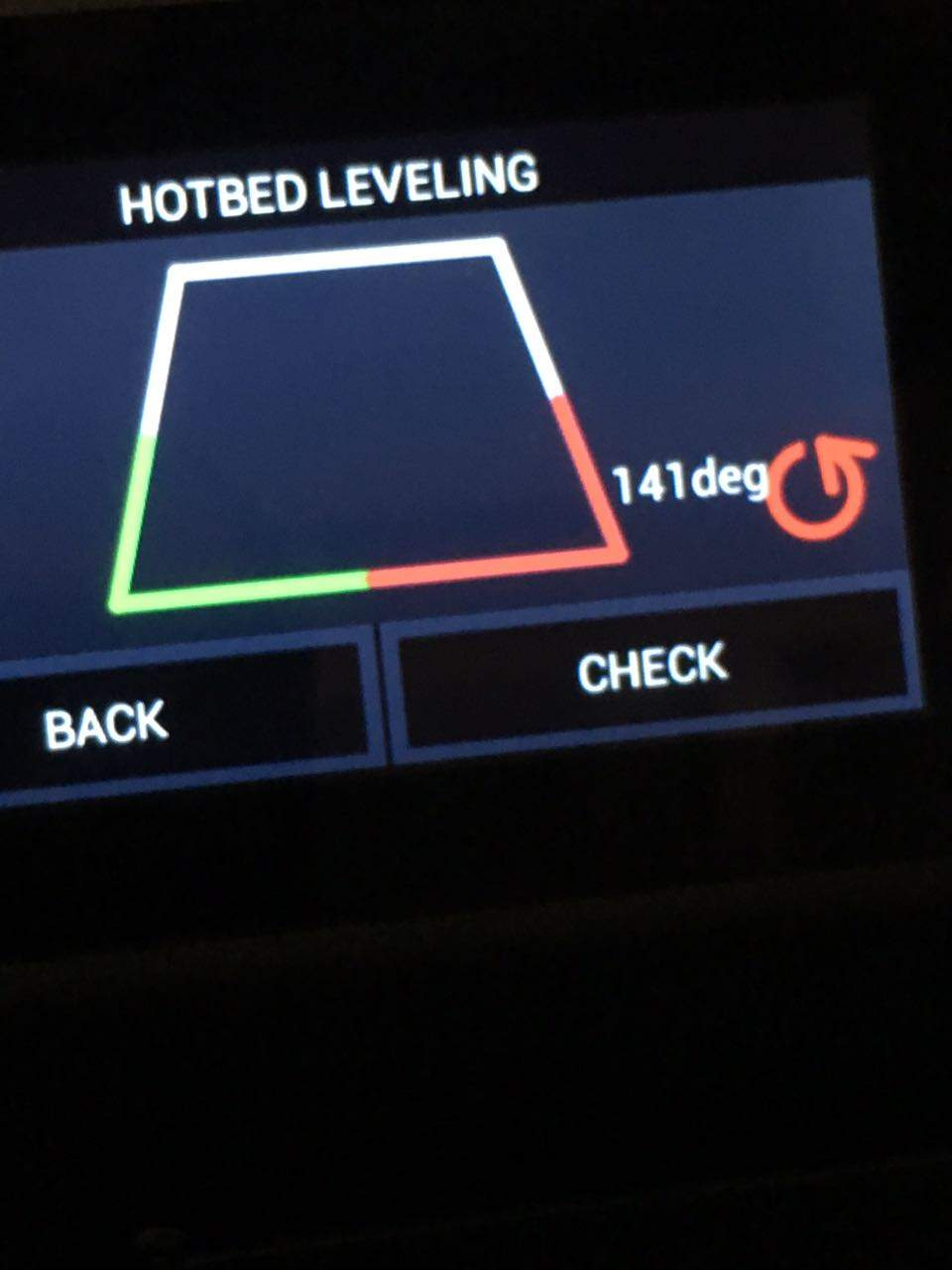

The table at the printer is heated with auto calibration. Autocalibration solved quite interesting. After passing through the four points on the screen, it is displayed how many degrees to turn the adjusting screw to the corresponding place on the table.

Further, the operation is repeated, and if necessary, the adjustment is performed more accurately. Everything is quite clear and simple.

Video calibration process.

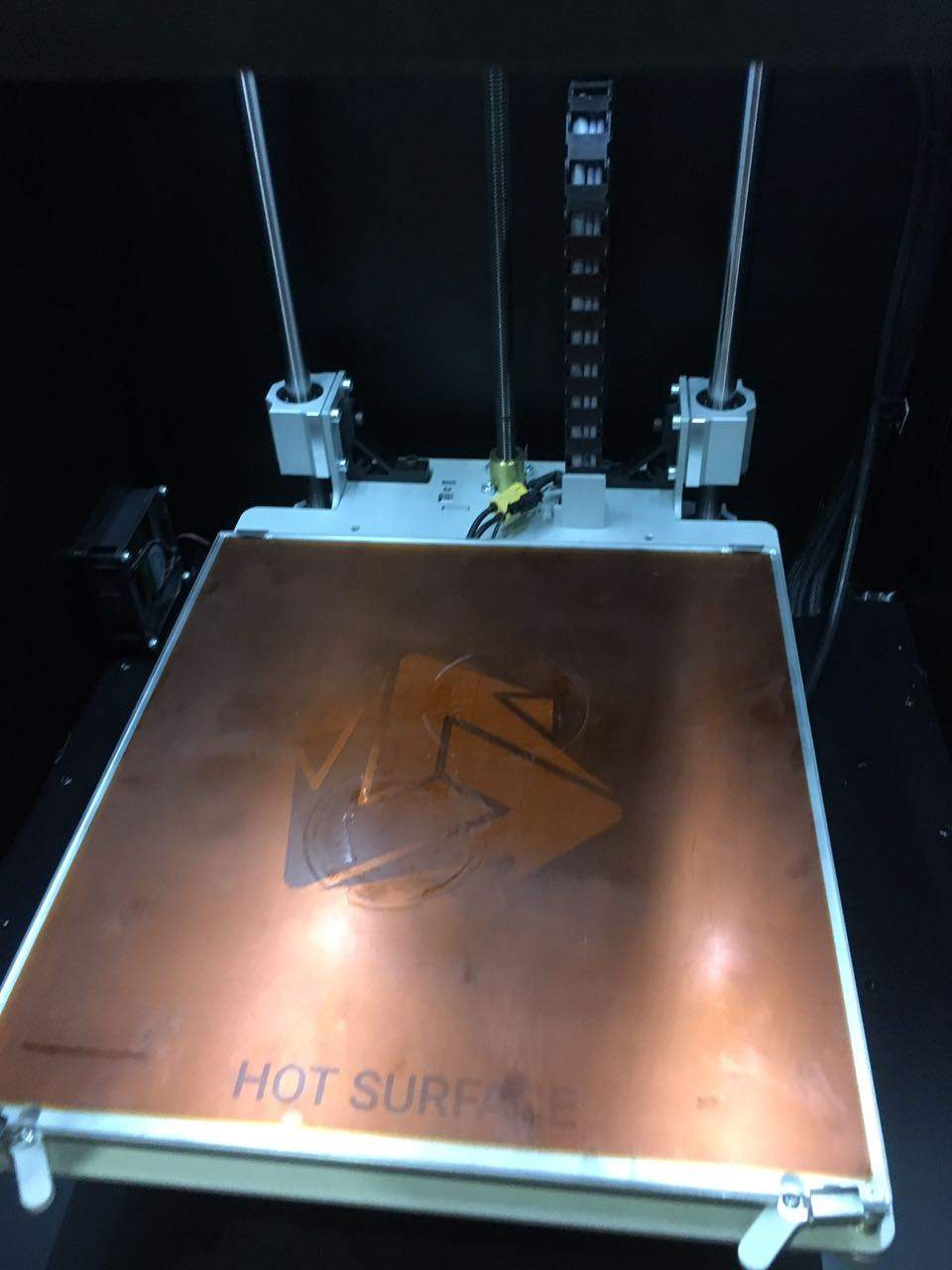

The heated table has a removable glass surface. The photo has a Kapton sheet stuck on it to increase adhesion. The manufacturer offers two quality adhesion solutions.

The first is a kapton tape.

The second is DIMAFIX lacquer. This decision was not widely encountered in Russia.

Judging by the manufacturer from Spain, this is one of the variations on the theme of mega-popular lacquer Nelly.

You can control a 3D printer as standard - via a usb cable. There is the option of remote control over a local network, via an Ethernet interface. Naturally, there is actually a mandatory port in each 3D printer for an SD card.

Electronics in the printer of its own design. Produced by the manufacturer independently in Poland. And not, like many 3D printers, a Chinese variation on the Arduino.

As we said above, the printer is equipped with a touch screen to control. The menu is quite simple and intuitive.

Below is the photo of the settings menu - SETUP. As you can see, besides the calibration menu of the heated table (which we described earlier), there is a menu for changing the nozzle.

Nozzle Change Menu

As you know, the nozzle must be unscrewed in a heated state. Using this menu, the printer heats the nozzle to the optimum temperature for a replacement operation.

We did not begin to remove all possible modes in the menu, because it is very simple. And it can be mastered by any operator of a 3D printer without problems.

The printer can use as standard software. So own software from the manufacturer.

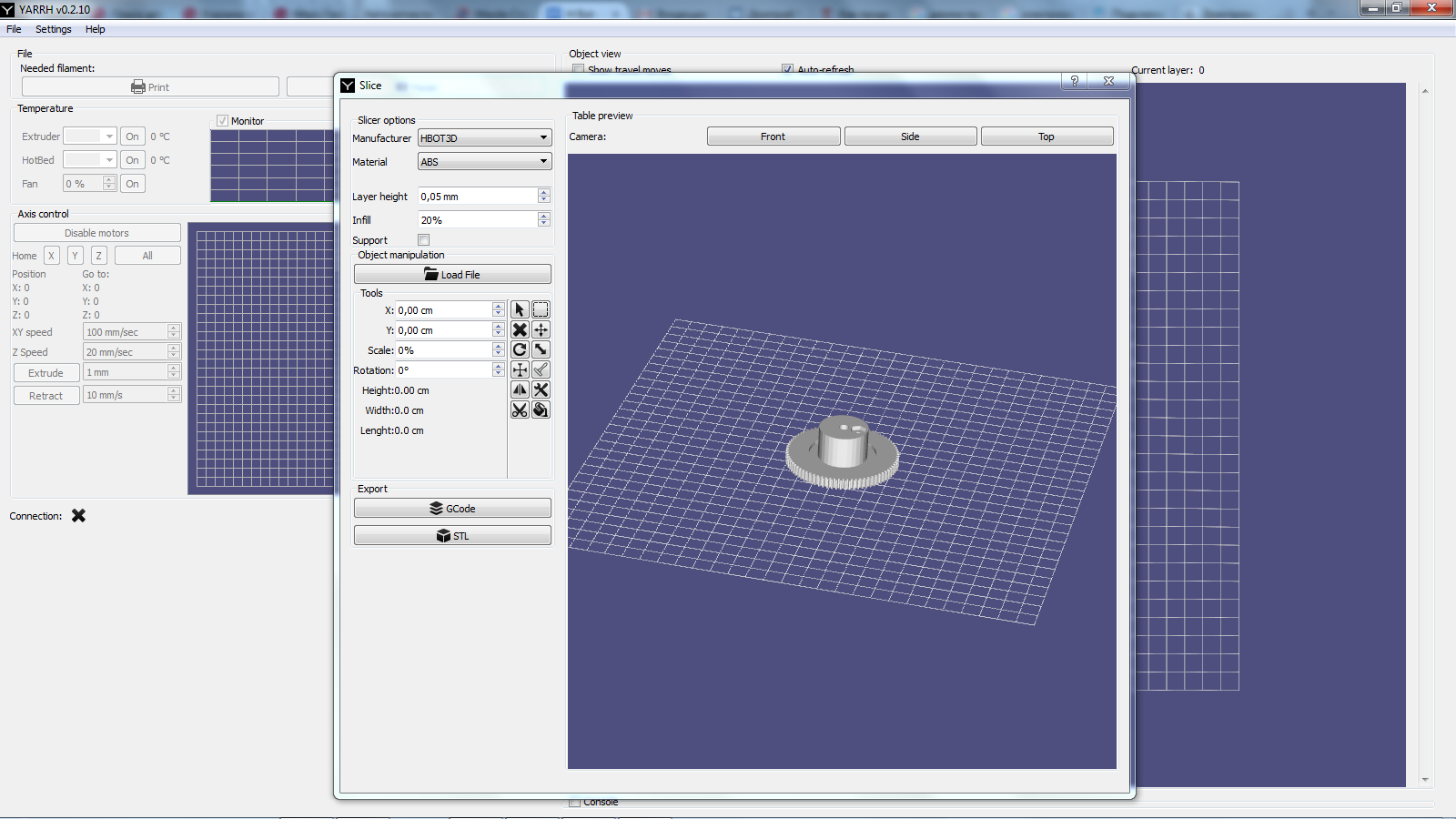

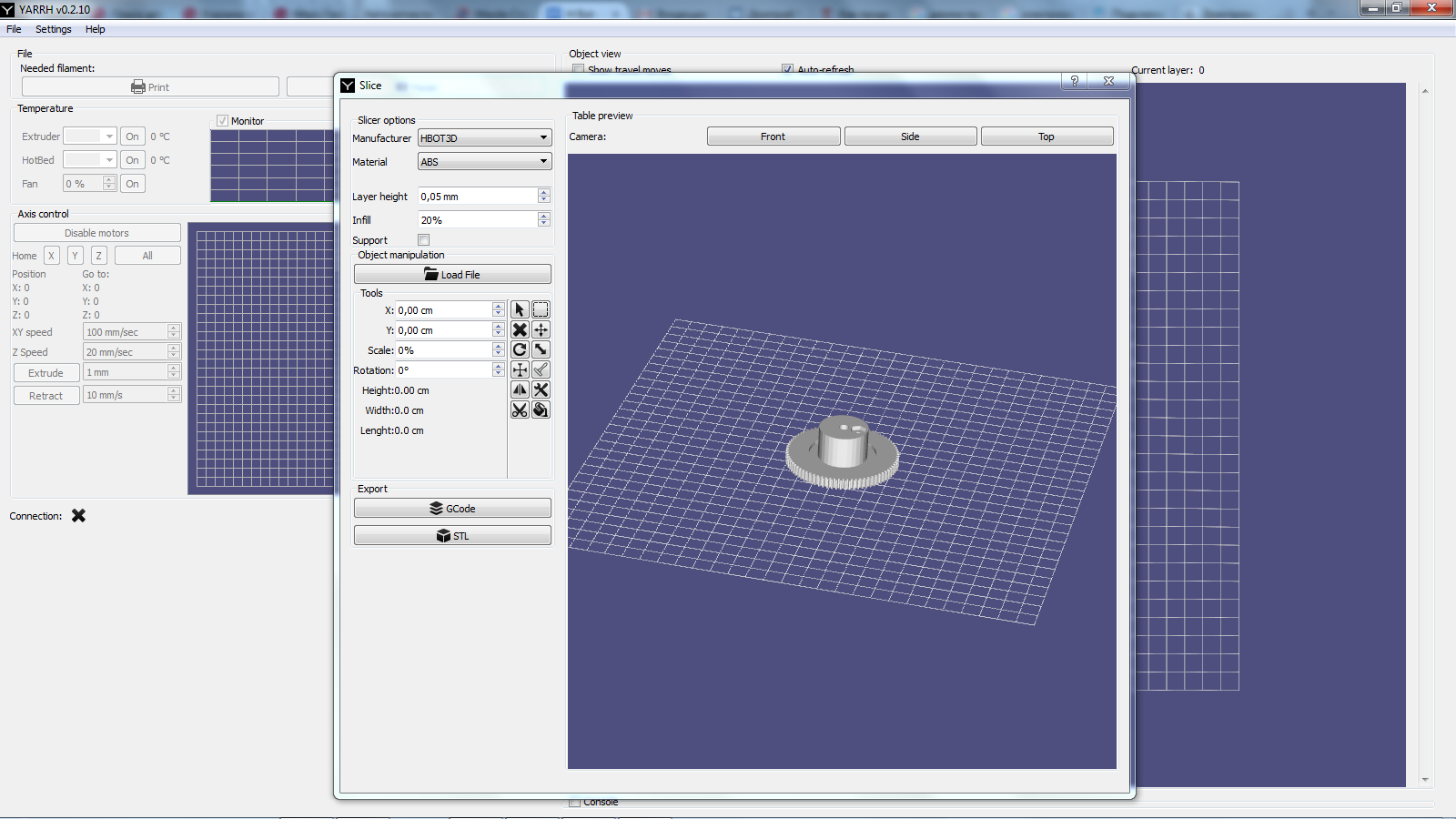

The program is called YARRH and can be downloaded for free from the website of the printer manufacturer.

Works and "slitsit" program quickly. This is a considerable plus compared to many free programs that work unhurriedly, to put it most correctly.

In addition, the printer is supplied with a commercial slicer Simplify3D for free.

Print

A small video about the printing process, which you can read.

Below are examples of products printed on the HBOT 3D F300 3D printer.

What are our personal impressions of the printer? Qualitatively assembled, professional equipment. The use of components made in Europe immediately leaves the impression that this is not a cheap hack, but created for serious work. The overall reasonableness of the design, and ease of use, make it clear that the manufacturer has created a finished product, ready to work out of the box.

We personally liked the printer very much. Your opinion, readers, can make a photo in which we tried to show the most interesting decisions of designers.

Our company is already engaged in signing a dealer agreement with the manufacturer. In the near future it will be signed. Orders for this equipment are accepted. Approximate delivery time - 25 working days. You can place an order either through our website or by e-mail sales@3dtool.ru .

And now goes on the world stage, the manufacturer HBot from the Polish city of Wroclaw. He announced himself, in-house, professional HBot 3D F300 3D printer.

For the first time in Russia, this 3D printer was demonstrated at the recently held Moscow exhibition ROSMOULD 2017.

We visited this exhibition and talked with representatives of the manufacturer, as well as carefully studied the HBOT 3D F300 3D printer. And in this article we want to share with readers our impressions about this very interesting car.

The printer is primarily focused on professional use. We would even say on the production. What is interesting about this printer?

Specifications

- Material used for 3D printing: PLA, ABS, ABS, ASA, HIPS, H-WOOD, PET-G, H-GLASS, TPU.

- Printing area: 300 x 300 x 300mm;

- Layer height: from 50 microns;

- Thread Diameter: 2.85mm;

- Extruder positioning accuracy: 0.1 mm;

- The diameter of the nozzle: 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm, 1 mm;

- Print speed: up to 150 mm / s;

- Availability of heated platform: Yes,

- Power of a heating element of a platform: 300 W;

- Number of print heads: 1;

- Connecting a 3D printer to a computer: USB, SD;

- Supported file formats: STL, OBJ, AMF;

- Power consumption: 480 W;

- Power supply: 110 - 230 VAC (± 10%);

- Dimensions: 560 x 570 x 700 mm;

HBot has a large print area of 300x300x300mm. This allows him to create fairly large products. The closed case and the heated table, allow to print plastic with high shrinkage (ABS).

Housing

The printer is built on an aluminum frame, on which metal walls are hung. The design on the frame is quite tough, which immediately leads to the conclusion that such decisions will clearly contribute to good accuracy and speed of printing. In a design of the printer metal details are used as much as possible. From which we can conclude that the printer is focused on intensive operation, and not at home use.

The printer is equipped with two transparent doors to access the workspace. Why two? Firstly, in order not to make one huge door with which it will not be very convenient to work. And secondly, thanks to this design, a rigid frame is formed, which will ensure print quality. This is clearly seen in the photo above, where there are two openings, it is just separated by one of the edges of the frame.

The design of the printer is quite minimalistic. On the front surface there is only the power button, and the touch screen control and at the bottom a place for installing an SD card.

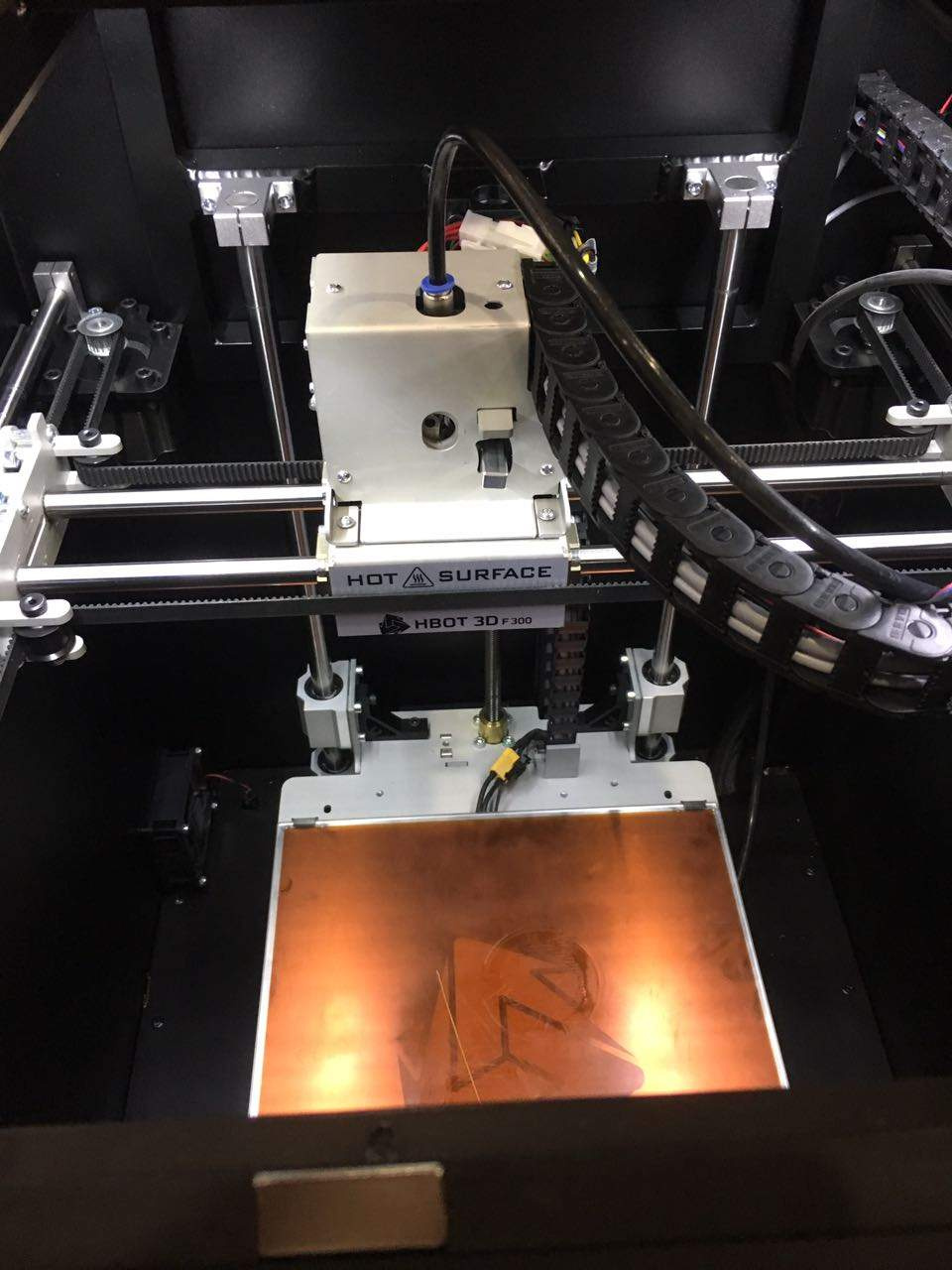

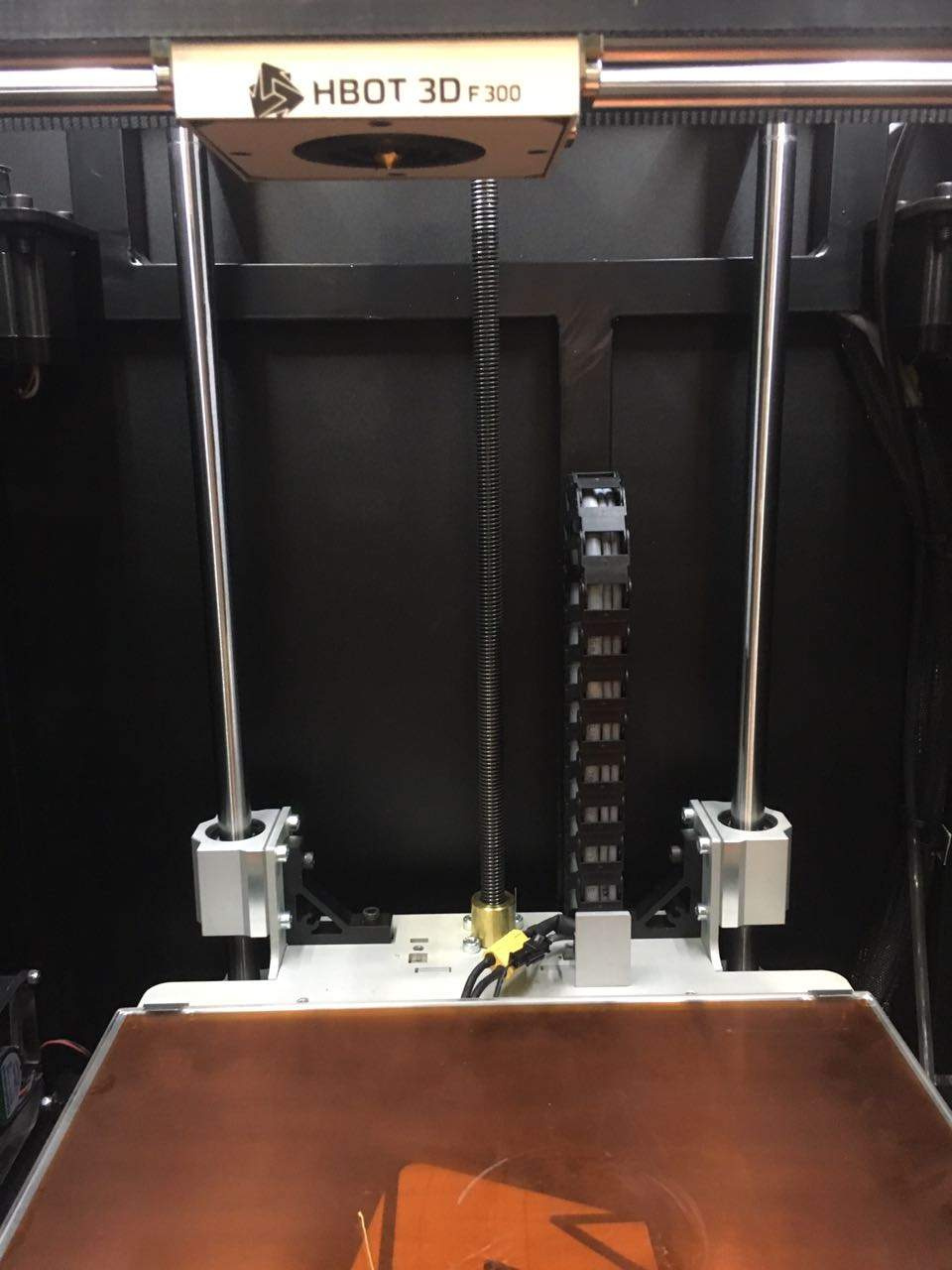

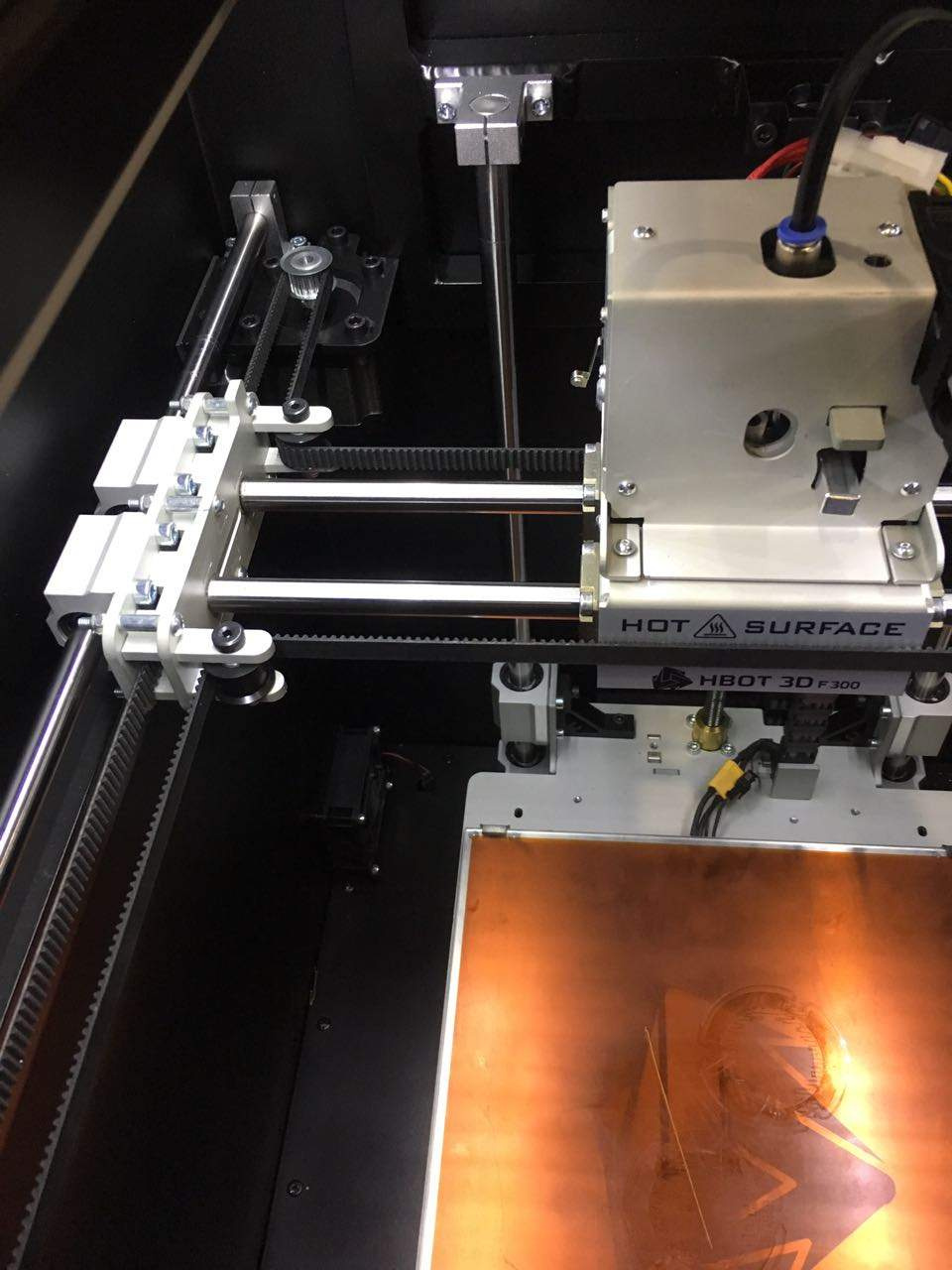

Mechanics

All kinematics is based on the h-bot scheme. This is what the printer name tells us. In the photo you can see the lack of printed parts in the design. Only metal, only hardcore. Estimate the thickness of the frame, which can be seen on the back of the printer

The creators of the printer did not hesitate to use thick hardened shafts in the design. This will clearly benefit the print quality of the printer.

Along the Z axis, guides with a diameter of 16mm are used. This avoids any hints of wobbling and greatly adds points in print quality.

In the course of communication, we found out that all components are of European production. Stepper motors such as the production of the Czech Republic, which has always been famous for the high quality of its products. ŠKODA, Česká Zbrojovka, Tatra, Aero Vodochody - the whole world knows the name of these engineering companies.

Build quality can be estimated by the photo.

A 12mm shaft is used along the XY axes, which is also a rather serious decision.

As we understood, the design uses 8 mm wide belts, and not like most 6 mm 3D printers.

Looking at this massive structure, you may get the impression that you cannot achieve high speed here. We all know what measures are used to facilitate the carriage, extruder in other printers.

But here the manufacturer claims a print speed of up to 150 mm / sec. How can this be achieved? And look at the components: powerful stepper motors, wide belts and precision linear bearings, red-hot shafts. All this contributes to high speed and print quality.

Extruder

The printer uses a direct extruder with a non-standard solution for plastic 2.85 mm. Yes Yes exactly. Apparently the manufacturer has serious arguments for such a decision.

The extruder is optimized for printing with various flexible materials. This is for him no difficulty. It can heat up to 270 ° C, which makes it possible to print the vast majority of plastics on the market.

Extruder nozzle removable. Nozzles with different diameters up to 1 mm can be installed. Given the size of the print camera 300x300x300mm, this is a very useful factor when printing large models. What is the use? When printing large products, printing time becomes critical. In order to reduce printing time, you can use nozzles of larger diameter. This feature is implemented in this printer.

Table

The table at the printer is heated with auto calibration. Autocalibration solved quite interesting. After passing through the four points on the screen, it is displayed how many degrees to turn the adjusting screw to the corresponding place on the table.

Further, the operation is repeated, and if necessary, the adjustment is performed more accurately. Everything is quite clear and simple.

Video calibration process.

The heated table has a removable glass surface. The photo has a Kapton sheet stuck on it to increase adhesion. The manufacturer offers two quality adhesion solutions.

The first is a kapton tape.

The second is DIMAFIX lacquer. This decision was not widely encountered in Russia.

Judging by the manufacturer from Spain, this is one of the variations on the theme of mega-popular lacquer Nelly.

Interfaces

You can control a 3D printer as standard - via a usb cable. There is the option of remote control over a local network, via an Ethernet interface. Naturally, there is actually a mandatory port in each 3D printer for an SD card.

Electronics

Electronics in the printer of its own design. Produced by the manufacturer independently in Poland. And not, like many 3D printers, a Chinese variation on the Arduino.

Control screen

As we said above, the printer is equipped with a touch screen to control. The menu is quite simple and intuitive.

Below is the photo of the settings menu - SETUP. As you can see, besides the calibration menu of the heated table (which we described earlier), there is a menu for changing the nozzle.

Nozzle Change Menu

As you know, the nozzle must be unscrewed in a heated state. Using this menu, the printer heats the nozzle to the optimum temperature for a replacement operation.

We did not begin to remove all possible modes in the menu, because it is very simple. And it can be mastered by any operator of a 3D printer without problems.

Software

The printer can use as standard software. So own software from the manufacturer.

The program is called YARRH and can be downloaded for free from the website of the printer manufacturer.

Works and "slitsit" program quickly. This is a considerable plus compared to many free programs that work unhurriedly, to put it most correctly.

In addition, the printer is supplied with a commercial slicer Simplify3D for free.

A small video about the printing process, which you can read.

Below are examples of products printed on the HBOT 3D F300 3D printer.

General impressions

What are our personal impressions of the printer? Qualitatively assembled, professional equipment. The use of components made in Europe immediately leaves the impression that this is not a cheap hack, but created for serious work. The overall reasonableness of the design, and ease of use, make it clear that the manufacturer has created a finished product, ready to work out of the box.

We personally liked the printer very much. Your opinion, readers, can make a photo in which we tried to show the most interesting decisions of designers.

Our company is already engaged in signing a dealer agreement with the manufacturer. In the near future it will be signed. Orders for this equipment are accepted. Approximate delivery time - 25 working days. You can place an order either through our website or by e-mail sales@3dtool.ru .

All Articles