Bolt. Leapfrog Bolt

Good afternoon, dear readers of Geektimes! Last autumn, a rather interesting 3D printer Leapfrog Bolt was presented. And our company received one of the first “live” printers in Russia that can be “touched” and tested.

Its main distinguishing feature is two independent extruders that move along the same X axis. This gives the 3D printer the ability to print in the following modes:

• Conventional single nozzle printing

• Printing 2 materials

• Simultaneous printing of two parts at the same time

• Mirror print mode of two parts

Leapfrog Bolt is positioned as a professional solution for production and design tasks.

Here is a complete list of technical specifications:

• The material used for 3D printing: ABS, PLA, HIPS, PVA, PET, PP, PC, Nylon, Woodplastic, Birckplastic and many others.

• Printing area, mm: 320x330x205 (when printed with one extruder), 320x300x205 (when printed with two extruders).

• Body Material: Aluminum;

• Layer thickness: 0.05 - 0.35 mm (Layer thickness is adjusted by the printer software settings);

• Positioning accuracy: XY: 8 microns; Z: 10 microns;

• Availability of heated platform: Yes;

• Printing platform: 8 mm tempered glass;

• Number of printheads: 2;

• Diameter of the nozzle: 0.35 mm;

• Compatibility with software: Windows, Mac OS X, Linux;

• Print speed: up to 6 mm3 / s;

• Supported formats: STL, OBJ;

• Software: Materialize;

• Touch screen: 7 ”;

• Built-in WEB-camera: Yes;

• Connecting a 3D printer to a computer: The printer connects to the computer via a USB cable, USB connector, Wi-Fi, network (UTP);

• Overall: 723mmx831mmx801mm;

• Weight: 61 kg;

• Power consumption: 400W;

• Warranty: 1 year;

Let's look at Bolt and its features. As usual, let's start with the look.

This little white one on the left is the Leapfrog Bolt . Looks solid, is not it? Appearance and corresponds to the weight - 61 kg. As if confirming Boris Borzva’s famous phrase - “Weight is reliability. Weight is good ... "

Indeed, the printer with all its appearance shows that this is a serious industrial equipment. And not a toy for girls - office managers.

The printer housing is assembled on an aluminum frame, on which plastic decorative panels are fixed. Examine this monster from all sides. Front view.

The printer is made in a fairly concise design. A large part of the front surface of a 3D printer is taken by a transparent door that closes the work area. The door opens simply, for this it is enough to take it by the bottom edge and fold it up. No pens that complicate the design and tend to be cut off by “very strong” users. The large transparent surface allows you to observe the printing process, even while being at a distance from the printer.

On the front surface is also located 7 "touch screen control. At the bottom of the USB port for Flash-cards and the power button, with a nice blue backlight.

On the right side of the printer, located in a niche, two coils with plastic.

As you can see, a niche allows you to install large coils up to one kilogram.

Installation of plastic is made conveniently and does not cause difficulties for anyone.

Left view of the printer.

There are no coils, just a blank wall with a logo. According to the logic of simplified design, it would make sense to place the plastic coils on different sides of the printer, as is often done.

Extruders are independent and each of them work from their side. But the designers were guided primarily by the ease of use of the equipment.

Agree, it is much more convenient to change plastic on one side. And do not run around a fairly large printer. And when placing the machine in the room, you will need to provide access only to the front and one side area, and not from all sides. This can be quite critical in a small room, given the size of the Leapfrog .

Open the lid and see what's inside.

As we can see, the workspace has a blue backlight. Qualitatively made, solid massive details, do not leave behind a feeling of structural fragility.

Even the door mount looks very reliable, compared to other printers, which often have a weak spot.

It is seen that the design is designed for industrial use. Inspect the "insides".

The left carriage houses the drives for the drives of extruders along the X axis. Each extruder moves along the X axis using a separate drive belt. All construction is made by stamping from three-millimeter metal.

Right carriage similar design. Only naturally without engines.

A little higher to the right is the HEPA filter that cleans the air from the fumes that occur when printing.

The desktop is made of tempered glass. It is easy enough to remove it, having turned two clamps.

The working surface can heat up to 90C. This is sufficient for printing with most plastics. And given the fully enclosed print chamber with temperature control, you can print without any problems using any materials, including those with high shrinkage. Such as ABS and Nylon.

For ease of use of the printer, the calibration table is semi-automatic. The process is very simple and will not cause problems even for a novice user.

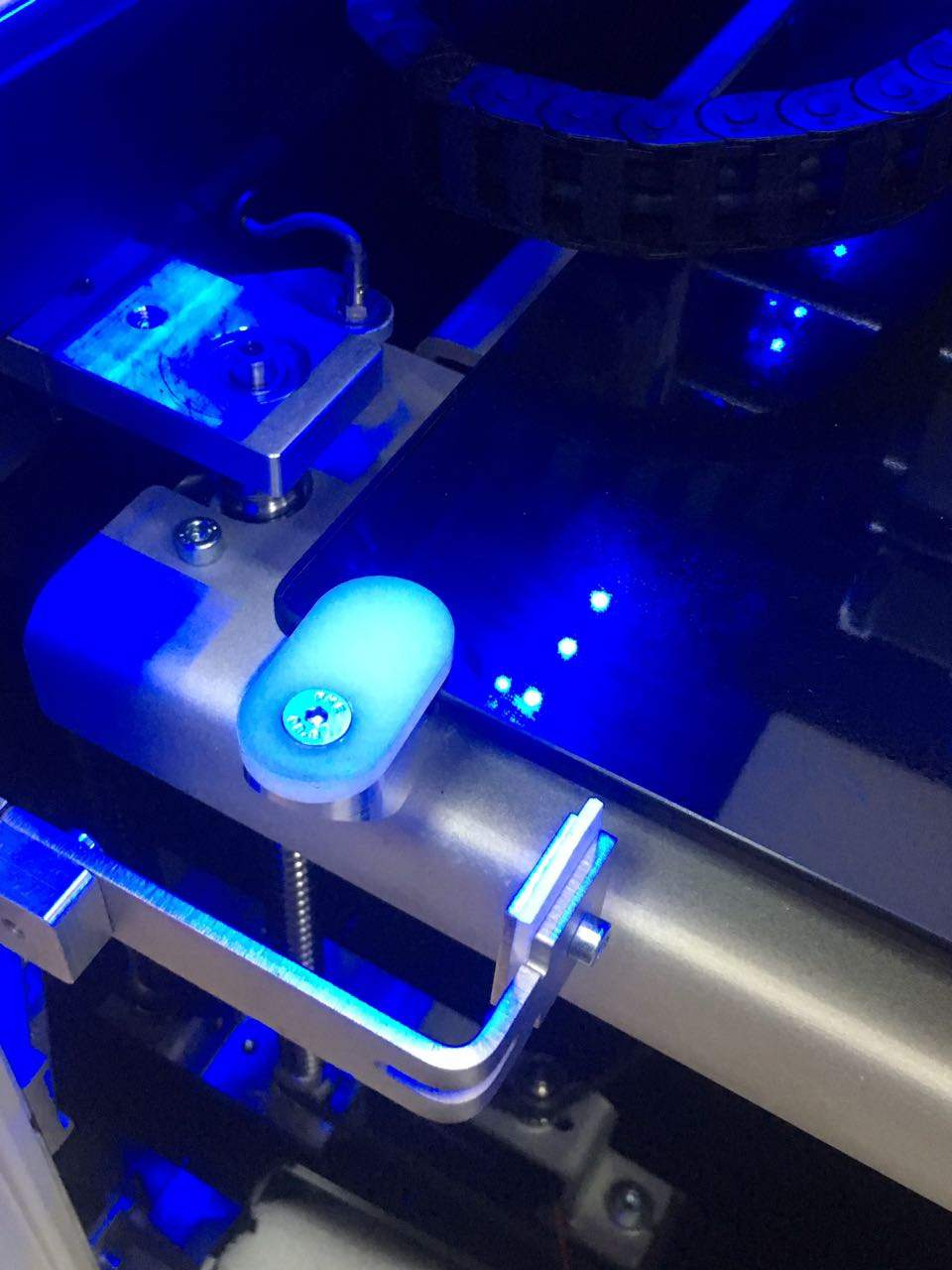

View of the table on the right side.

Below is a photo of the table on the left side. You can observe the "diapers", for cleaning the nozzle from plastic, mounted on the L-shaped bracket. With the help of this node, the plastic from the nozzle flowing out of work is cleaned. This allows you to avoid building a technological "tower", which greatly reduces the time of two-material printing. And improves its quality.

The table is moved using ball screws located on both sides.

Below in the photo you can see the drive unit for ball screw. The same stamped construction, similar to drives on the X axis. Everything looks solid and reliable.

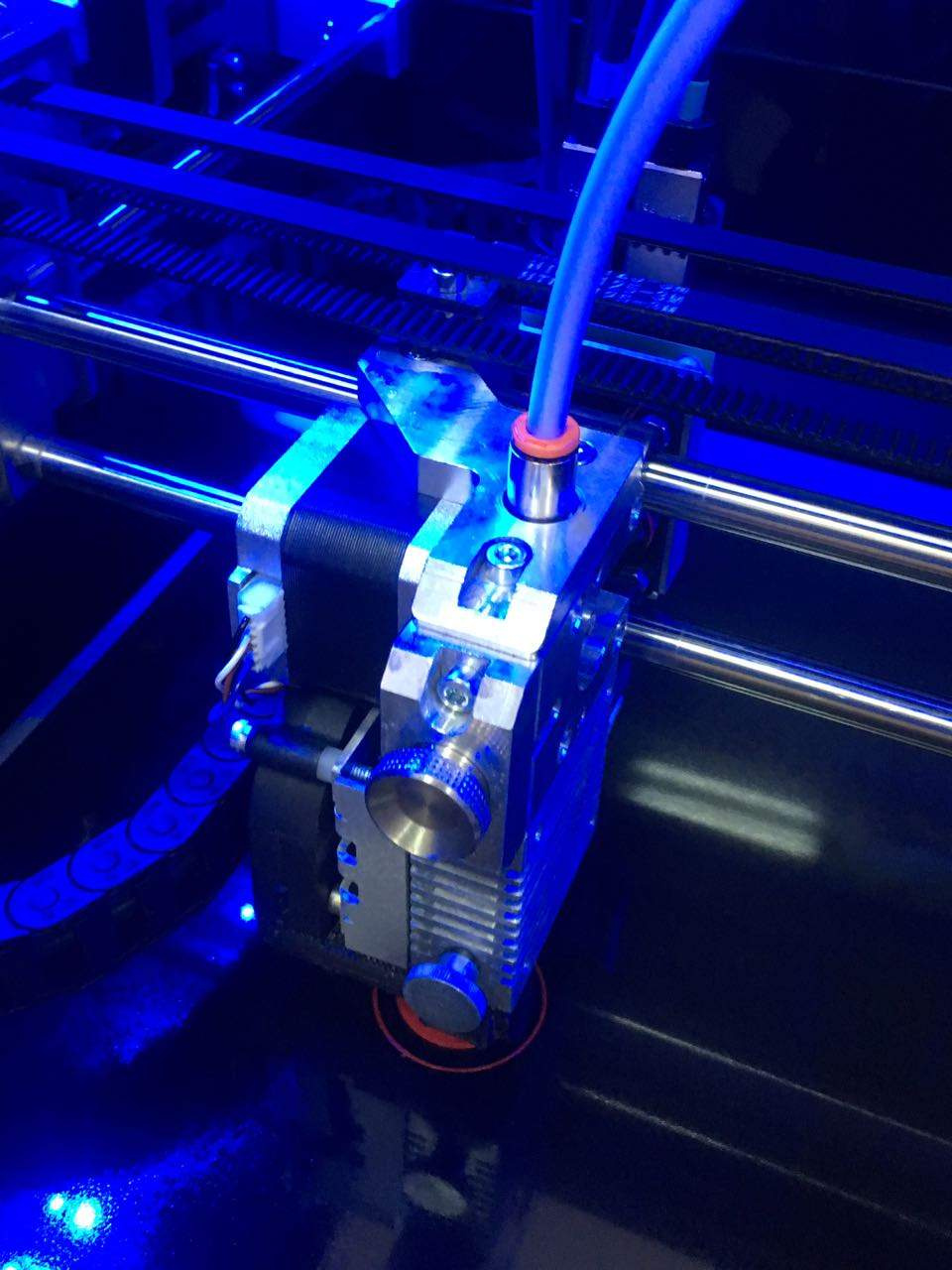

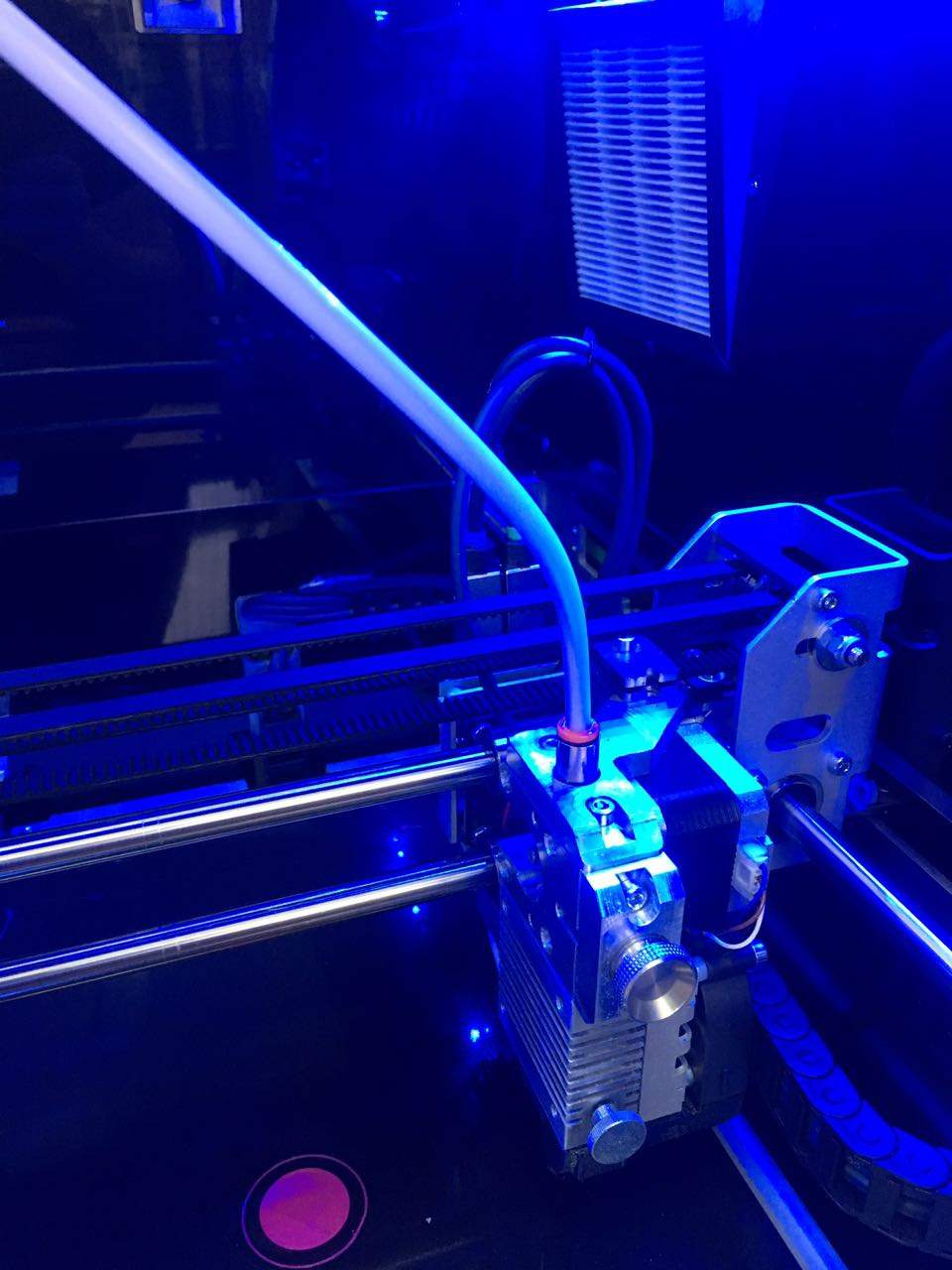

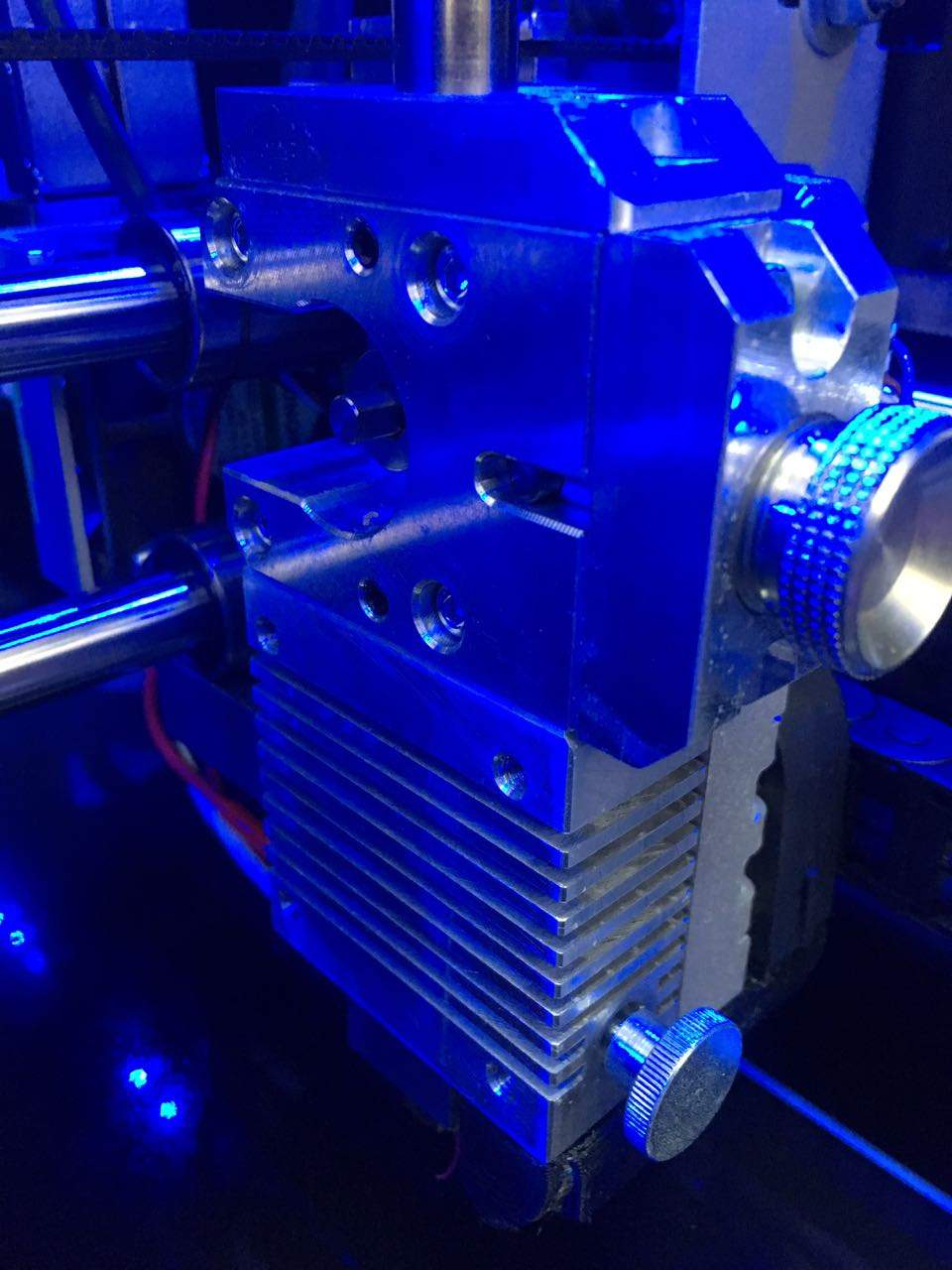

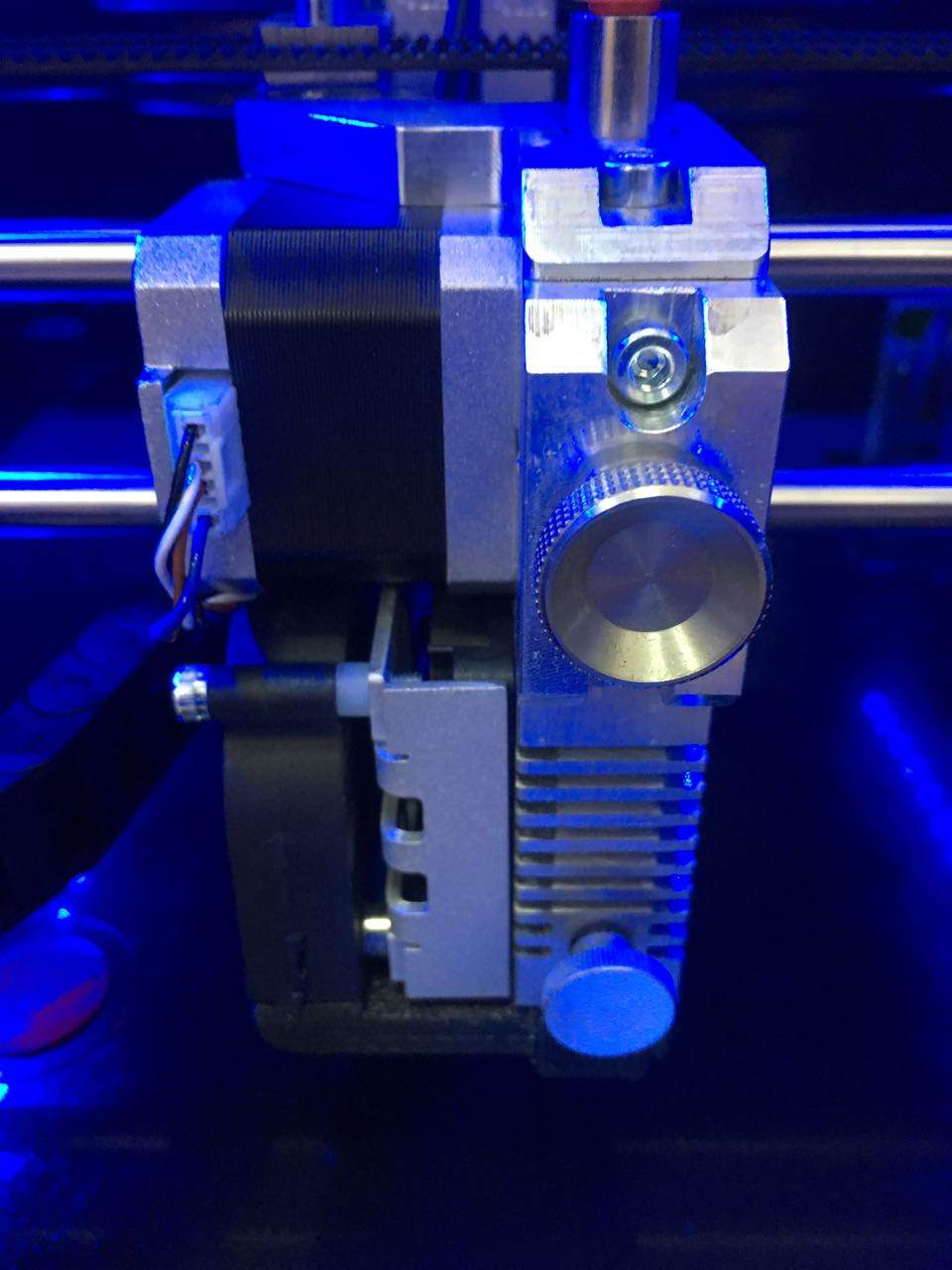

Let us turn to that part of the printer, which actually speaks and prints. That is, to the extruder. Leapfrog Bolt is equipped with two direct extruders. Their design is identical, except that one is a mirror image of the second.

In a standard complete set the nozzle can heat up to 265. This allows you to print most materials. There is also a high-temperature modification that can heat up to 360 ° C. This will allow printing with materials with a high melting point.

Another great feature of Leapfrog Bolt . The design of the extruder allows you to quickly change the hot-end with the nozzle. In order to install a nozzle with a different diameter, we do not need to risk getting burned. After all, the nozzle is usually replaced in a heated state with a special key. It is enough to disconnect one connector and turn the lock.

After that, the entire node can be pulled down. This can be done in a cold state and without the use of special tools. For a professional device, in which it may be necessary to frequently change the diameter of the nozzle, for different tasks, a very timely decision. And of course, reducing the risk of burn is a very important advantage.

In the photo you can see the handle lock handle. It is located at the bottom of the extruder.

As we wrote above, the left and right extruder have a mirror design. Movement along the Y axis is common. But on the X axis, each of the extruders can move independently of the other. Thanks to this solution, the 3D printer can print in synchronous and mirror mode.

With synchronous printing, absolutely identical parts are created on both sides of the desktop.

In mirror print mode, parts are mirror copies. This is true when we need to create, for example, left and right symmetrical parts.

After inspecting the "insides" of the printer, a strong feeling of reliability and thoughtfulness of the structure was formed. Good quality and solidity can be seen in every detail.

With the device sorted out. It remains to learn how to manage a 3D printer, and what its capabilities.

The printer is controlled via the touch screen. The interface is thought out and easy to learn. Everything is quite clear. This can be seen in the photo below.

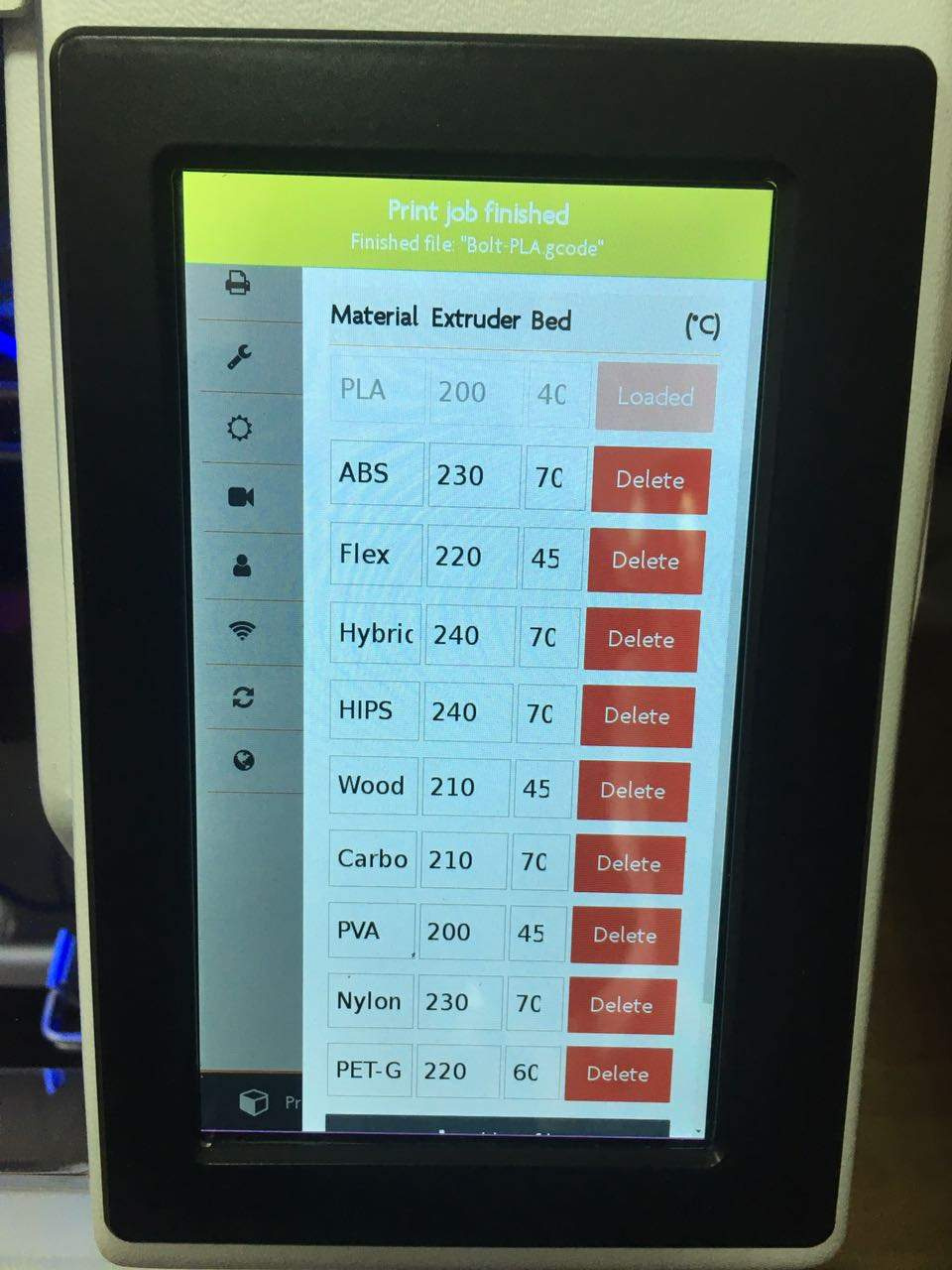

The choice of material for printing. Profiles of all basic materials are initially registered in the printer. You can add your own or remove embedded plastic profiles.

The screen during the printing process, in addition to the progress bar, has a visual display of the model that is currently on the desktop. You can also see the elapsed and predicted printing time.

The printer is equipped with a video camera. With the help of which, you can remotely monitor the printing process. You can also display the image on the control screen.

Printer screen after printing.

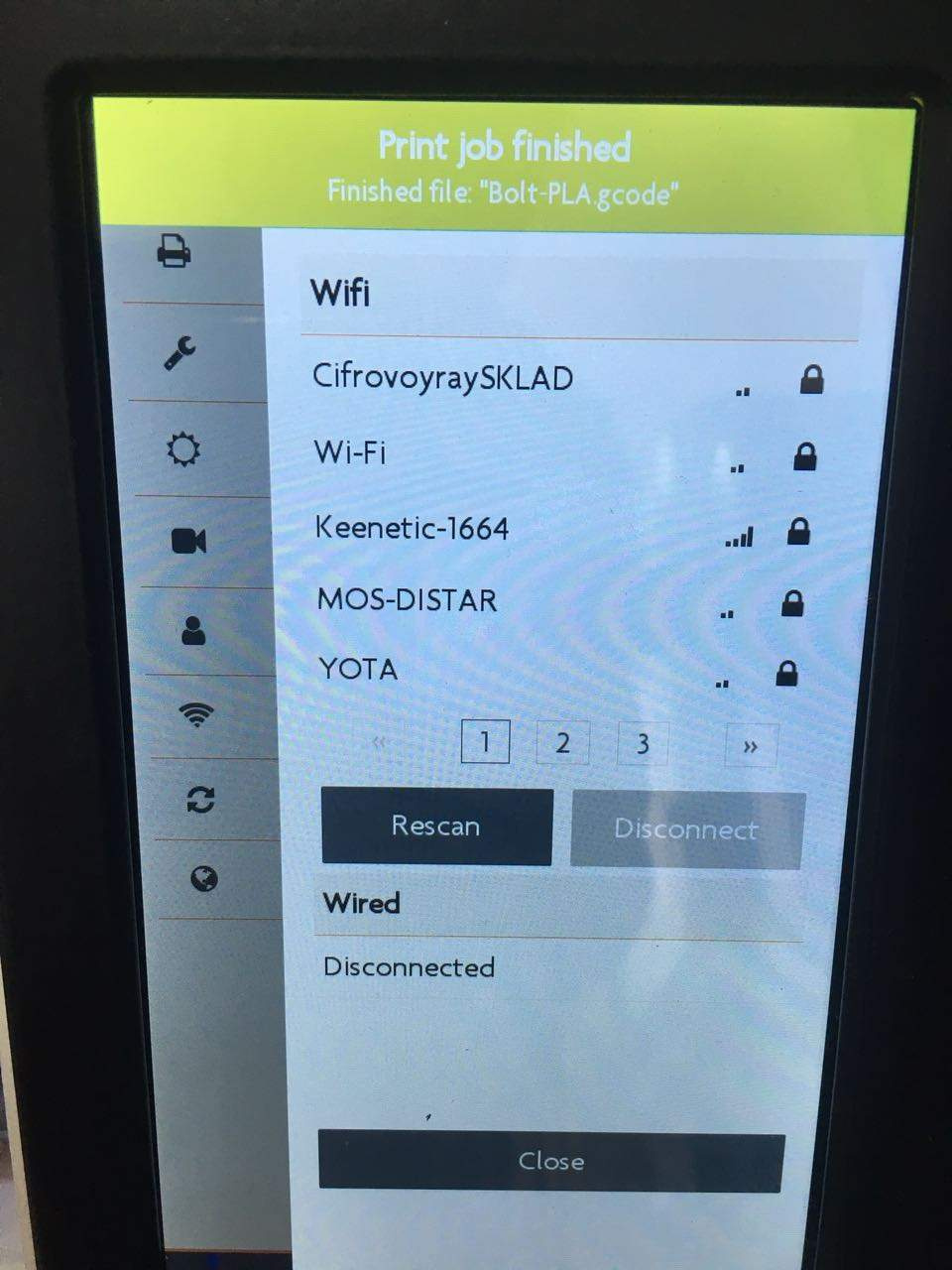

Wifi network selection screen. The printer is equipped with a wireless module that allows you to remotely control printing using a web interface.

In addition to WiFi, you can use a standard Ethernet network interface for remote control.

Remote control allows full setup before the printing process, as well as monitoring with a video camera. Using the Web interface does not require the installation of additional software. This allows you to control the printer from any computer, regardless of the operating system installed. In addition, the management process is available from any smartphone, without installing additional programs.

Naturally, the printer is equipped with a standard USB-interface.

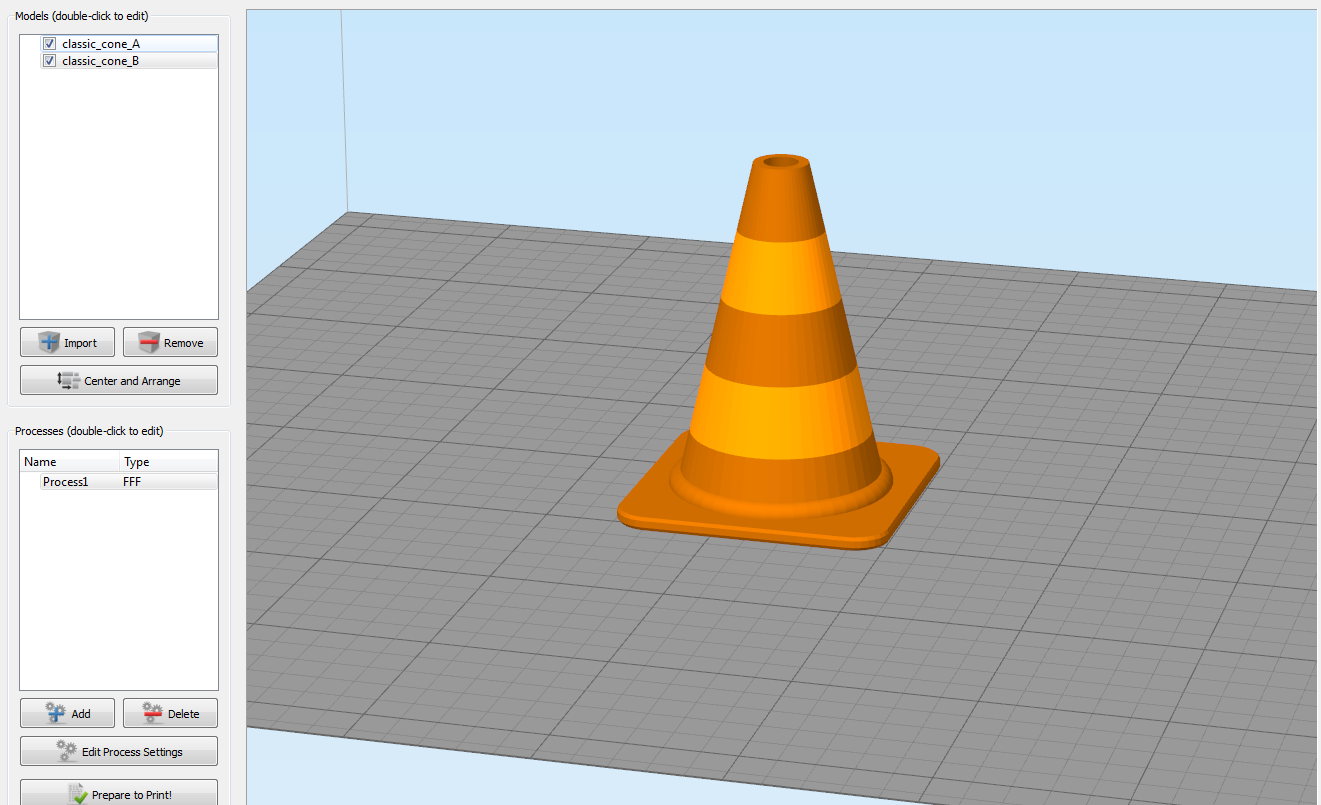

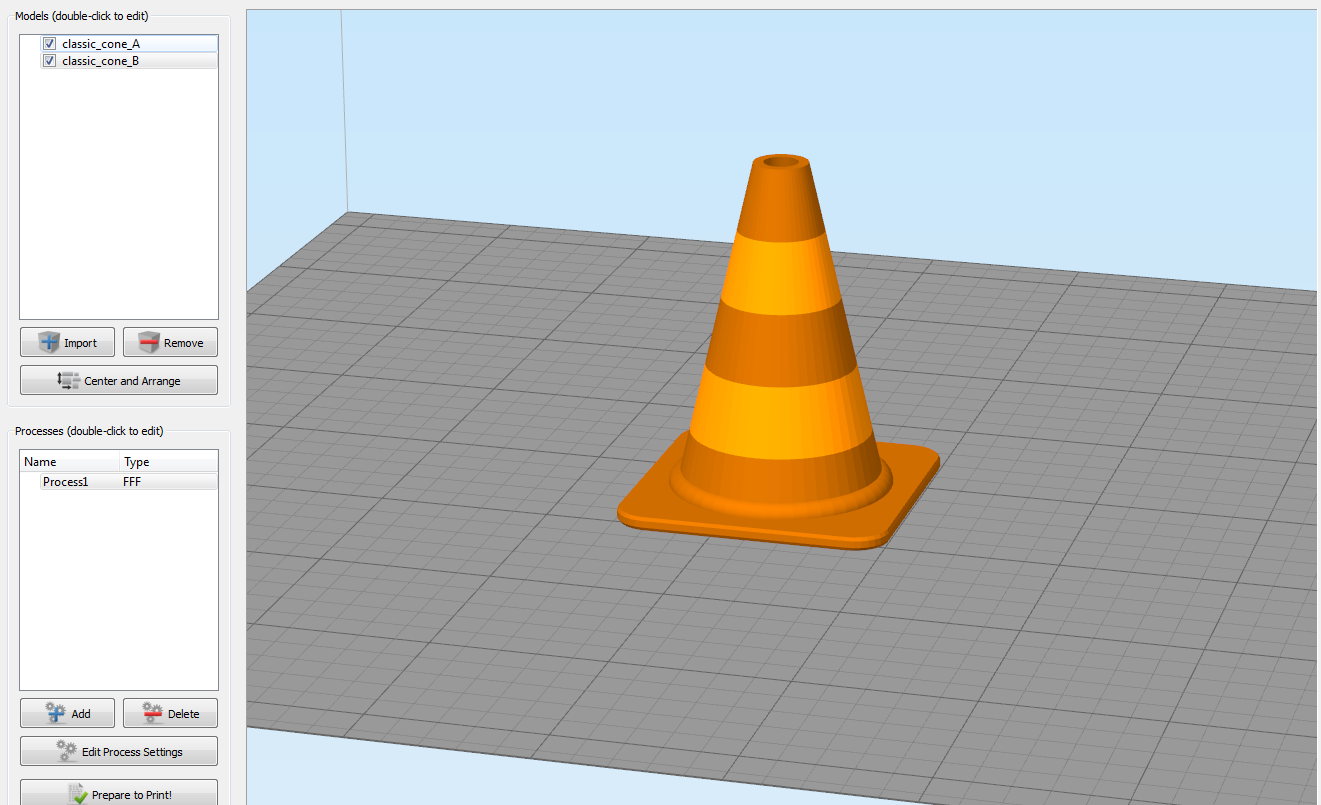

You can prepare a model for printing in almost any slicer. The printer itself before purchase can be packaged as in the original Creatr slicer . It can be downloaded free of charge from the manufacturer’s website.

You can also choose a complete set of all well-known commercial slicer Simplify3D . Printer buyers get it for free.

Print

Video of the printing process.

We decided to test the version of synchronous printing. In real use when printing multiple products, this results in a two-time saving of printing time. Two parts printed in synchronized mode.

Some people may have questions about print quality due to the massiveness of extruders. But the photo below closes all such questions. Parts created by Leapfrog Bolt have excellent surface and geometry.

At the end of the printing process, the 3D printer gave us two identical parts that differ only in color.

Exact printer mechanics produce excellent print quality.

Impressions of Leapfrog Bolt:

Reliable, solidly made, thoughtful machine for professional use.

Of the obvious advantages:

• Large print area;

• Printing 2 materials at high speed;

• Synchronous mode;

• Mirror mode;

• Convenient operation using the touch screen;

• Ability to remote control via the Web-interface;

• Ease of maintenance;

What do we have in the end? Large 3D printer designed for professional use. Buying a home will be overkill. But where you need to print a small series of parts, and the full set of features described above, Bolt will be in its place. Remote control is created so that several people can use the printer. For example, design or design department of the company.

You can see live and purchase Leapfrog Bolt at the office of our company 3Dtool at the address: Moscow, ul. Dorogobuzhskaya d. 14, bld. 40, 3 floor, office 303 (2nd entrance).

Photos of the Leapfrog Bolt printer are made at the 3Dtool service center, where all 3D printers are tested before being sent to customers.

More information about the printer can be found on our website 3Dtool.ru .

What is it?

Its main distinguishing feature is two independent extruders that move along the same X axis. This gives the 3D printer the ability to print in the following modes:

• Conventional single nozzle printing

• Printing 2 materials

• Simultaneous printing of two parts at the same time

• Mirror print mode of two parts

Leapfrog Bolt is positioned as a professional solution for production and design tasks.

Here is a complete list of technical specifications:

• The material used for 3D printing: ABS, PLA, HIPS, PVA, PET, PP, PC, Nylon, Woodplastic, Birckplastic and many others.

• Printing area, mm: 320x330x205 (when printed with one extruder), 320x300x205 (when printed with two extruders).

• Body Material: Aluminum;

• Layer thickness: 0.05 - 0.35 mm (Layer thickness is adjusted by the printer software settings);

• Positioning accuracy: XY: 8 microns; Z: 10 microns;

• Availability of heated platform: Yes;

• Printing platform: 8 mm tempered glass;

• Number of printheads: 2;

• Diameter of the nozzle: 0.35 mm;

• Compatibility with software: Windows, Mac OS X, Linux;

• Print speed: up to 6 mm3 / s;

• Supported formats: STL, OBJ;

• Software: Materialize;

• Touch screen: 7 ”;

• Built-in WEB-camera: Yes;

• Connecting a 3D printer to a computer: The printer connects to the computer via a USB cable, USB connector, Wi-Fi, network (UTP);

• Overall: 723mmx831mmx801mm;

• Weight: 61 kg;

• Power consumption: 400W;

• Warranty: 1 year;

Appearance

Let's look at Bolt and its features. As usual, let's start with the look.

This little white one on the left is the Leapfrog Bolt . Looks solid, is not it? Appearance and corresponds to the weight - 61 kg. As if confirming Boris Borzva’s famous phrase - “Weight is reliability. Weight is good ... "

Indeed, the printer with all its appearance shows that this is a serious industrial equipment. And not a toy for girls - office managers.

The printer housing is assembled on an aluminum frame, on which plastic decorative panels are fixed. Examine this monster from all sides. Front view.

The printer is made in a fairly concise design. A large part of the front surface of a 3D printer is taken by a transparent door that closes the work area. The door opens simply, for this it is enough to take it by the bottom edge and fold it up. No pens that complicate the design and tend to be cut off by “very strong” users. The large transparent surface allows you to observe the printing process, even while being at a distance from the printer.

On the front surface is also located 7 "touch screen control. At the bottom of the USB port for Flash-cards and the power button, with a nice blue backlight.

On the right side of the printer, located in a niche, two coils with plastic.

As you can see, a niche allows you to install large coils up to one kilogram.

Installation of plastic is made conveniently and does not cause difficulties for anyone.

Left view of the printer.

There are no coils, just a blank wall with a logo. According to the logic of simplified design, it would make sense to place the plastic coils on different sides of the printer, as is often done.

Extruders are independent and each of them work from their side. But the designers were guided primarily by the ease of use of the equipment.

Agree, it is much more convenient to change plastic on one side. And do not run around a fairly large printer. And when placing the machine in the room, you will need to provide access only to the front and one side area, and not from all sides. This can be quite critical in a small room, given the size of the Leapfrog .

Internal organization

Open the lid and see what's inside.

As we can see, the workspace has a blue backlight. Qualitatively made, solid massive details, do not leave behind a feeling of structural fragility.

Even the door mount looks very reliable, compared to other printers, which often have a weak spot.

It is seen that the design is designed for industrial use. Inspect the "insides".

The left carriage houses the drives for the drives of extruders along the X axis. Each extruder moves along the X axis using a separate drive belt. All construction is made by stamping from three-millimeter metal.

Right carriage similar design. Only naturally without engines.

A little higher to the right is the HEPA filter that cleans the air from the fumes that occur when printing.

Desktop

The desktop is made of tempered glass. It is easy enough to remove it, having turned two clamps.

The working surface can heat up to 90C. This is sufficient for printing with most plastics. And given the fully enclosed print chamber with temperature control, you can print without any problems using any materials, including those with high shrinkage. Such as ABS and Nylon.

For ease of use of the printer, the calibration table is semi-automatic. The process is very simple and will not cause problems even for a novice user.

View of the table on the right side.

Below is a photo of the table on the left side. You can observe the "diapers", for cleaning the nozzle from plastic, mounted on the L-shaped bracket. With the help of this node, the plastic from the nozzle flowing out of work is cleaned. This allows you to avoid building a technological "tower", which greatly reduces the time of two-material printing. And improves its quality.

The table is moved using ball screws located on both sides.

Below in the photo you can see the drive unit for ball screw. The same stamped construction, similar to drives on the X axis. Everything looks solid and reliable.

Extruder

Let us turn to that part of the printer, which actually speaks and prints. That is, to the extruder. Leapfrog Bolt is equipped with two direct extruders. Their design is identical, except that one is a mirror image of the second.

In a standard complete set the nozzle can heat up to 265. This allows you to print most materials. There is also a high-temperature modification that can heat up to 360 ° C. This will allow printing with materials with a high melting point.

Another great feature of Leapfrog Bolt . The design of the extruder allows you to quickly change the hot-end with the nozzle. In order to install a nozzle with a different diameter, we do not need to risk getting burned. After all, the nozzle is usually replaced in a heated state with a special key. It is enough to disconnect one connector and turn the lock.

After that, the entire node can be pulled down. This can be done in a cold state and without the use of special tools. For a professional device, in which it may be necessary to frequently change the diameter of the nozzle, for different tasks, a very timely decision. And of course, reducing the risk of burn is a very important advantage.

In the photo you can see the handle lock handle. It is located at the bottom of the extruder.

As we wrote above, the left and right extruder have a mirror design. Movement along the Y axis is common. But on the X axis, each of the extruders can move independently of the other. Thanks to this solution, the 3D printer can print in synchronous and mirror mode.

With synchronous printing, absolutely identical parts are created on both sides of the desktop.

In mirror print mode, parts are mirror copies. This is true when we need to create, for example, left and right symmetrical parts.

After inspecting the "insides" of the printer, a strong feeling of reliability and thoughtfulness of the structure was formed. Good quality and solidity can be seen in every detail.

Control

With the device sorted out. It remains to learn how to manage a 3D printer, and what its capabilities.

The printer is controlled via the touch screen. The interface is thought out and easy to learn. Everything is quite clear. This can be seen in the photo below.

The choice of material for printing. Profiles of all basic materials are initially registered in the printer. You can add your own or remove embedded plastic profiles.

The screen during the printing process, in addition to the progress bar, has a visual display of the model that is currently on the desktop. You can also see the elapsed and predicted printing time.

The printer is equipped with a video camera. With the help of which, you can remotely monitor the printing process. You can also display the image on the control screen.

Printer screen after printing.

Interfaces

Wifi network selection screen. The printer is equipped with a wireless module that allows you to remotely control printing using a web interface.

In addition to WiFi, you can use a standard Ethernet network interface for remote control.

Remote control allows full setup before the printing process, as well as monitoring with a video camera. Using the Web interface does not require the installation of additional software. This allows you to control the printer from any computer, regardless of the operating system installed. In addition, the management process is available from any smartphone, without installing additional programs.

Naturally, the printer is equipped with a standard USB-interface.

Software

You can prepare a model for printing in almost any slicer. The printer itself before purchase can be packaged as in the original Creatr slicer . It can be downloaded free of charge from the manufacturer’s website.

You can also choose a complete set of all well-known commercial slicer Simplify3D . Printer buyers get it for free.

Video of the printing process.

We decided to test the version of synchronous printing. In real use when printing multiple products, this results in a two-time saving of printing time. Two parts printed in synchronized mode.

Some people may have questions about print quality due to the massiveness of extruders. But the photo below closes all such questions. Parts created by Leapfrog Bolt have excellent surface and geometry.

At the end of the printing process, the 3D printer gave us two identical parts that differ only in color.

Exact printer mechanics produce excellent print quality.

Impressions of Leapfrog Bolt:

Reliable, solidly made, thoughtful machine for professional use.

Of the obvious advantages:

• Large print area;

• Printing 2 materials at high speed;

• Synchronous mode;

• Mirror mode;

• Convenient operation using the touch screen;

• Ability to remote control via the Web-interface;

• Ease of maintenance;

What do we have in the end? Large 3D printer designed for professional use. Buying a home will be overkill. But where you need to print a small series of parts, and the full set of features described above, Bolt will be in its place. Remote control is created so that several people can use the printer. For example, design or design department of the company.

You can see live and purchase Leapfrog Bolt at the office of our company 3Dtool at the address: Moscow, ul. Dorogobuzhskaya d. 14, bld. 40, 3 floor, office 303 (2nd entrance).

Photos of the Leapfrog Bolt printer are made at the 3Dtool service center, where all 3D printers are tested before being sent to customers.

More information about the printer can be found on our website 3Dtool.ru .

All Articles